I'm building a 3-way active crossover system and was originally planning on just attaching each driver directly to a single amplifier. However there is non-zero risk here, e.g. if a pair of crossover-to-amplifier cables (they're XLR coming out of a DCX2496) are swapped then I could maybe dump a whole bunch of 30-300Hz into my tweeter and make it Very Unhappy. Amplifier-to-speaker connections will be unswappable because I'm using a Neutrik 8-pole for each channel.

Is there a standard practice for protecting tweeters (and maybe mids), e.g. with a series capacitor? Preferably one that doesn't significantly affect the phase, which a series C will do. Or do people just follow a rigorous start-at-the-bottom sequence and lots of labels when installing crossover-to-amplifier cables?

Is there a standard practice for protecting tweeters (and maybe mids), e.g. with a series capacitor? Preferably one that doesn't significantly affect the phase, which a series C will do. Or do people just follow a rigorous start-at-the-bottom sequence and lots of labels when installing crossover-to-amplifier cables?

This is commonly done since hiccups sometimes happen.

Try a cap in series with the tweeter. Set the corner to be at least an octave below the crossover point. This of course will not protect from the driver being over-driven (that requires different solution e.g. bulb, or polyswitch or zenners). Don't worry too much about the phase shift. Most of the shift occurs up a the corner freq.

Try a cap in series with the tweeter. Set the corner to be at least an octave below the crossover point. This of course will not protect from the driver being over-driven (that requires different solution e.g. bulb, or polyswitch or zenners). Don't worry too much about the phase shift. Most of the shift occurs up a the corner freq.

You would surely get it right?

You could use a controller to ensure there are no errors.

The Sabien Work Station is a good starting point.

You could use a controller to ensure there are no errors.

The Sabien Work Station is a good starting point.

I (finally) pulled the series capacitors out of my cabinets several years ago after seeing (and hearing) how much they messed up phase and frequency response.Or do people just follow a rigorous start-at-the-bottom sequence and lots of labels when installing crossover-to-amplifier cables?

Amplifier-to-speaker connections will be unswappable because I'm using a Neutrik 8-pole for each channel.

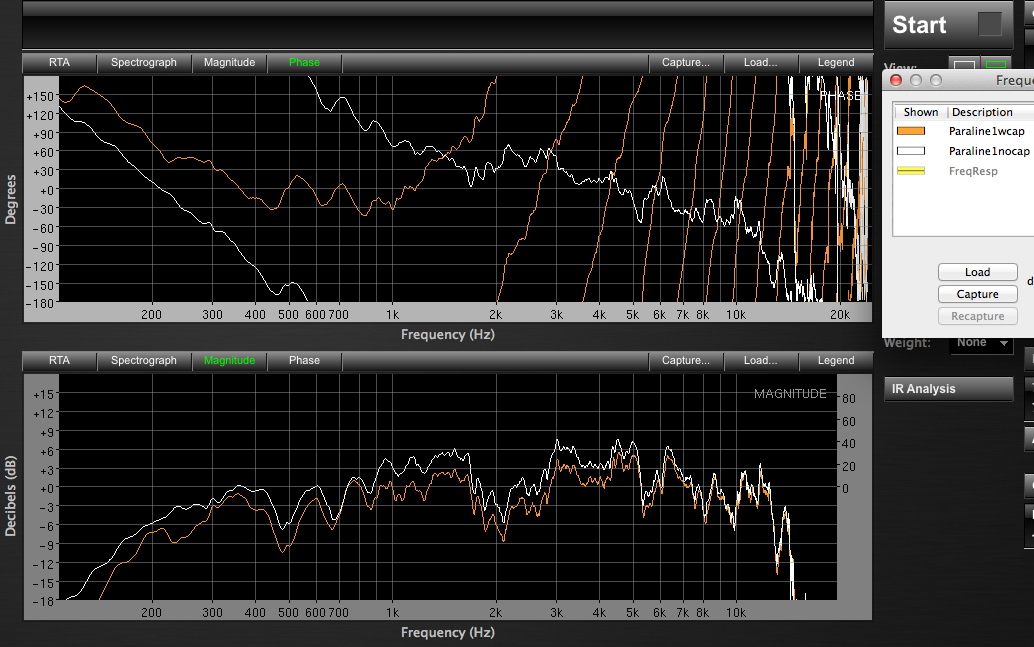

The graphs below show what an 18 mfd series cap does to a 16 ohm horn driver response- nothing like one would expect, and would not afford any protection other than from DC.

On large 4 way systems I used multi connectors between the DSP and amp racks to eliminate human patch error.

On my smaller 3 way system I color code the amps and snake XLRs, but have made some mistakes which I have caught.

As always, I run up a multi-way system starting with the LF amps at low level (like you they are unswappable, using EP6) then MF, and HF- it is easy to notice if HF is coming out of a woofer.

So far, have not lost a HF driver due to mis patch in 40 years of multi-way use.

Art

Attachments

Well, I would hope I would get it right but who knows 😉

And the prices of 47uF MKPs (for 2 octaves below the lowest reasonable crossover point) isn't something that makes me happy when I have 6 tweeters to protect. Given that the protection capacitors EACH cost 2/3 as much as the tweeters that they protect, I think I might just leave them out. I'd have to be clumsy enough to blow 4 of my 6 tweeters before the protection capacitors are economical...

And the prices of 47uF MKPs (for 2 octaves below the lowest reasonable crossover point) isn't something that makes me happy when I have 6 tweeters to protect. Given that the protection capacitors EACH cost 2/3 as much as the tweeters that they protect, I think I might just leave them out. I'd have to be clumsy enough to blow 4 of my 6 tweeters before the protection capacitors are economical...

Confused here..why would you need more than one such cap per HF channel of each active xover

I wouldn't, but there are 6 channels: 6 woofers, 6 mids, 6 tweeters.

My DCX2496 only has six channels. Are you using three units?

Yes.

Sub management is currently done by my receiver but it has only one pre-out for that so maybe one day in future I'll move my subs to a 4th DCX, or eBay the lot and move to a different DSP system with more channels and better analogue stages.

My experience is that accidents (wrong connections of cables and wrong order of power on/off) do happen. The need for protection (at speaker/driver cable) depends on the price and availability of the tweeter. A 20€ driver does not need a 40€ high-class cap. But I would not leave a 300-600€ RAAL ribbon without it.

The protection is not only for mis-wiring. What about DC offset at the power amp output? I'm running ribbon tweeters for an active 3 way, really concerned that the tweeters need protection, but don't want the messed up phase response.

I read from pi speakers crossover design document - an L pad on the tweeter can help damp the peaks caused by a crossover or protection cap. Just a 0.5db L pad... does that make sense?

I read from pi speakers crossover design document - an L pad on the tweeter can help damp the peaks caused by a crossover or protection cap. Just a 0.5db L pad... does that make sense?

The best would be to design the active crossover's transfer function with the added highpass pole of the output cap in mind.

Regards

Charles

Regards

Charles

You can get colour coding rings/inserts for Neutrik XLR sockets and connectors. Also, you could choose a black connector for HF and silver for all the others, for example.

The best would be to design the active crossover's transfer function with the added highpass pole of the output cap in mind.

Regards

Charles

In theory that is the better approach. With the OP's set up it would probably not be possible.

The protection is not only for mis-wiring. What about DC offset at the power amp output? I'm running ribbon tweeters for an active 3 way, really concerned that the tweeters need protection, but don't want the messed up phase response.

I read from pi speakers crossover design document - an L pad on the tweeter can help damp the peaks caused by a crossover or protection cap. Just a 0.5db L pad... does that make sense?

I don't think steady-state offset will be a problem (for now) as I'm driving tweets with LM3886, which claim 1mV (typ) - 10mV (max) input offset, so 20-200mV output offset, or 5mW DC. I can't see it being a problem thermally but am not sure if a slight voicecoil offset will be an issue.

wrt turn-on transients, I'm not sure. I think all my amps have mute input (the mids+highs definitely do) but I haven't arranged a global mute bus to coordinate them with sources; they each just do a little turn-on mute. Amp power-up is requested using the 12V signal line out of my HT receiver.

This L-pad; you mean a pair of capacitors acting as a voltage divider? Unless I'm mistaken, the (approx. 4.5+4.5j) impedance of the tweeter is going to swamp all but an incredibly large parallel C, and still require a very large (33-47uF) series C to keep the roll-off out of my crossover's transition band. 33uF would get me about 800Hz.

The best would be to design the active crossover's transfer function with the added highpass pole of the output cap in mind.

Ignoring difficulties in specifying the digital filter in the presence of this capacitor, that seems somewhat inflexible. It means being locked into one particular crossover frequency and topology with no opportunity to easily adjust xover tuning, which I think is a big reason for having digital actives.

In theory that is the better approach. With the OP's set up it would probably not be possible.

I think the DCX has a 3rd-order option but getting it to sum flat will be a lot harder and certainly more-manual than just setting it up in "link" mode where it adjusts the complementary HP and LP filters to match each other. I'd rather just start with LR4 and know that the C rolloff (if any) is at about 2 octaves below my crossover and somewhere well down in the driver's natural rolloff.

In other words, I want the capacitor to be sonically irrelevant. And not cost me $170 for a set of them. And only be installed if necessary for protection.

Last edited:

Back when I used tweeter caps on my horns, I used polypropylene motor run capacitors. Those are a very high-quality capacitor, and are available commonly up to 100uF at reasonable cost. Like weltersys, I found that having a capacitor in series with the horn drivers had some negative effects, so these days the amp is DC coupled to the horn drivers. That's possible only because the amp (a First Watt J2) has no turn-on thump. Any substantial turn-on thump is likely to damage a horn driver.

Last edited:

Own the responsibility of setting up system correctly and skip the crappy caps, they just get in the way.

Like Art, I have never damaged a tweeter with active system due to operator error in setup.

I have damaged tweeter with amplifier that had nasty turn on/off thump. This should be non issue with LM3886 based amplifier.

Like Art, I have never damaged a tweeter with active system due to operator error in setup.

I have damaged tweeter with amplifier that had nasty turn on/off thump. This should be non issue with LM3886 based amplifier.

I don't know about the response, maybe the impedance of the driver on the horn would tell the tale, but I think something went wrong with this relative phase measurement.The graphs below show what an 18 mfd series cap does to a 16 ohm horn driver response- nothing like one would expect, and would not afford any protection other than from DC.

Yes, for some reason the delay time was changed.I don't know about the response, maybe the impedance of the driver on the horn would tell the tale, but I think something went wrong with this relative phase measurement.

IIRC, I left the cabinet and the mic in exactly the same position.

Although the capacitor should induce a phase lag, normally I'd think the added delay time (no cap 5.92 ms, with cap 6.58 ms) would have flattened out the phase response, but just put it behind by 90 degrees.

Smaart's "Auto sm" will calculate the correct time delay, but in this case it looks like it was somehow mistakenly changed to an incorrect value.

I have had some screen lock ups, the delay time probably reverted to a previous test after rebooting the program, and I did not check the time of the first test after rebooting.

At any rate, the frequency response differences are correct, and show up octaves above what I'd have expected.

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Protection C when using active crossovers?