I am currently working on a two-way ported passive design to act as my surrounds. This is my third design project and fourth build project (I built a predesigned Micro-Marty sub).

My first design and build was a fairly large two way build for my main L/R with Dayton RS-225-8 woofers and RST28A tweeters designed for a college project. I designed them with the help of a super friendly redditor. All design work was based on factory data and diffraction/enclosure simulations. It turned out good for my expectations.

My second build was a MTM center speaker using the same tweeter as before, but two RS150-4 woofers. Same thing, all just theoretical/simulation data used to design.

This go around I am using the RS150-8 and RST28A, but am trying to improve my process by taking and using my own measurements.

For FRD measurements I have a Dayton EMM-6 and Scarlett 2i2, I built a turntable/spinorama style stand to allow for off-axis measurements while keeping my drivers at the center of rotation. For ZMA I am just using a make shift DATs with resistors and my 2i2. I follow this guide here.

So far I have learned a decent amount and made quiet a few improvements that I will then propagate to my previous builds.

1. During initial impedance measurements I had a weird peak/dip in my woofer's impedance. Found it to be a cabinet resonance. Gluing a brace/strip of MDF between my two side walls fixed that. I am sure that is an issue for my 8in mains that can be fixed.

2. I found during initial farfield measurements of my tweeter that I had some pretty nasty peaks and dips from about 2-6 kHz. I found out part of my issue was having a surface mounted instead of flush mounted tweeter. I fixed that, and my results got better but still some improvement left on the table. I at the same time went ahead and flush mounted the tweeter on all my previous builds.

3. In a continued effort to fix my tweeter dip, I rounded my edges with a 1/2in radius roundover bit. I will eventually roundover the edges on all my other builds too. The result I got from this was slight improvement in my 2.5-4 kHz dip, but not much. It did also decrease the hard fall off I had above 10 kHz by a significant amount.

Here is an album that shows some of my measurements throughout my process and what the actual speakers look like.

So now I am trying to figure out what else I can do or should be looking for before taking a final spin measurement and starting crossover design.

I still have a significant dip between 2.5-4 kHz. I believe the biggest culprit here is having a symmetrical/centered tweeter. I know the obvious answer is make my tweeter off center, but that also sets me back a lot because it means cutting off my baffle, cutting a new one, and then repeating the counter sink and round over process. I was suggested at looking into a waveguide if I don't want to rebuild the baffle entirely, but I haven't found any that would fit on my 7.5in wide baffle that also has the proper mounting for the RST28A. I will likely look into the SEOS-8 for when I go to revise my mains build, as it will fit on those.

There are a couple of things I know now that it is slightly too late for this go around, unless I want to back track a lot, that I will use going forward. Making my tweeter off center and getting my tweeter as close to my woofer as possible.

So my questions now are:

1. Is there anything I can do to help mitigate my dip that is almost certainly (VituixCAD diffraction simulator agrees) due to my centered tweeter, without cutting off and rebuilding my entire baffle? I have been suggested 3d print a waveguide, but that is a whole can of worms I am not sure I want to spend the time learning about, plus I have heard wave guides have their own trade offs. As well, I was told I could put some F-13 felt around the tweeter, but then I have to find a way to make that aesthetically pleasing.

2. I made my tweeter flush, could I expect any benefit of making my woofer flush as well?

3. How do I properly handle merging my near field and far field woofer measurements seeing as I have a port? The previously listed VituixCAD guide suggests taking SPL nearfield measurements from the woofer and the port, but I am not sure how to handle merging both of those with the farfield.

4. I have largely just been looking at my SPL and ZMA results for things to improve. Are there other factors I should investigate before carrying on?

My first design and build was a fairly large two way build for my main L/R with Dayton RS-225-8 woofers and RST28A tweeters designed for a college project. I designed them with the help of a super friendly redditor. All design work was based on factory data and diffraction/enclosure simulations. It turned out good for my expectations.

My second build was a MTM center speaker using the same tweeter as before, but two RS150-4 woofers. Same thing, all just theoretical/simulation data used to design.

This go around I am using the RS150-8 and RST28A, but am trying to improve my process by taking and using my own measurements.

For FRD measurements I have a Dayton EMM-6 and Scarlett 2i2, I built a turntable/spinorama style stand to allow for off-axis measurements while keeping my drivers at the center of rotation. For ZMA I am just using a make shift DATs with resistors and my 2i2. I follow this guide here.

So far I have learned a decent amount and made quiet a few improvements that I will then propagate to my previous builds.

1. During initial impedance measurements I had a weird peak/dip in my woofer's impedance. Found it to be a cabinet resonance. Gluing a brace/strip of MDF between my two side walls fixed that. I am sure that is an issue for my 8in mains that can be fixed.

2. I found during initial farfield measurements of my tweeter that I had some pretty nasty peaks and dips from about 2-6 kHz. I found out part of my issue was having a surface mounted instead of flush mounted tweeter. I fixed that, and my results got better but still some improvement left on the table. I at the same time went ahead and flush mounted the tweeter on all my previous builds.

3. In a continued effort to fix my tweeter dip, I rounded my edges with a 1/2in radius roundover bit. I will eventually roundover the edges on all my other builds too. The result I got from this was slight improvement in my 2.5-4 kHz dip, but not much. It did also decrease the hard fall off I had above 10 kHz by a significant amount.

Here is an album that shows some of my measurements throughout my process and what the actual speakers look like.

So now I am trying to figure out what else I can do or should be looking for before taking a final spin measurement and starting crossover design.

I still have a significant dip between 2.5-4 kHz. I believe the biggest culprit here is having a symmetrical/centered tweeter. I know the obvious answer is make my tweeter off center, but that also sets me back a lot because it means cutting off my baffle, cutting a new one, and then repeating the counter sink and round over process. I was suggested at looking into a waveguide if I don't want to rebuild the baffle entirely, but I haven't found any that would fit on my 7.5in wide baffle that also has the proper mounting for the RST28A. I will likely look into the SEOS-8 for when I go to revise my mains build, as it will fit on those.

There are a couple of things I know now that it is slightly too late for this go around, unless I want to back track a lot, that I will use going forward. Making my tweeter off center and getting my tweeter as close to my woofer as possible.

So my questions now are:

1. Is there anything I can do to help mitigate my dip that is almost certainly (VituixCAD diffraction simulator agrees) due to my centered tweeter, without cutting off and rebuilding my entire baffle? I have been suggested 3d print a waveguide, but that is a whole can of worms I am not sure I want to spend the time learning about, plus I have heard wave guides have their own trade offs. As well, I was told I could put some F-13 felt around the tweeter, but then I have to find a way to make that aesthetically pleasing.

2. I made my tweeter flush, could I expect any benefit of making my woofer flush as well?

3. How do I properly handle merging my near field and far field woofer measurements seeing as I have a port? The previously listed VituixCAD guide suggests taking SPL nearfield measurements from the woofer and the port, but I am not sure how to handle merging both of those with the farfield.

4. I have largely just been looking at my SPL and ZMA results for things to improve. Are there other factors I should investigate before carrying on?

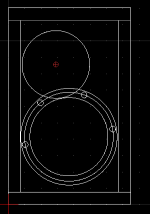

I am starting to consider rebuilding the baffle. Here is what I am thinking, with a flush mounted tweeter tucked under the woofer flange.

This puts my tweeter as close to my woofer as I can and as far off center as I can go without running in to my 1/2in roundover edge

This puts my tweeter as close to my woofer as I can and as far off center as I can go without running in to my 1/2in roundover edge

Attachments

Last edited:

That is pretty much the same configuration (mirror imaged) in a small 2-way i am assembling.

Your midBass is closer to the walls than i like, your tweeter has a quite large bezel, it could also probably be trimmed.

dave

Your midBass is closer to the walls than i like, your tweeter has a quite large bezel, it could also probably be trimmed.

dave

What is the theory/reasoning behind having the mid further from the walls? As for the tweeter bezel, if it wasn't metal, I would trim it. I can order the truncated faceplate for it, but I am in a race to get this done before the snow hits and halts building.

Last edited by a moderator:

I have built prototypes that had the driver too close to the sidewall and it could be heard. Just a small increase in width (15mm or so IIRC) made a bug difference.

Before figuring out where to put the tweeters on the boxes i am workign on was to place the tweeter bezel over the woofer basket, but then Bernie, who has a router, came to my rescue. The bezel is MUCH smaller on my tweeter.

dave

Before figuring out where to put the tweeters on the boxes i am workign on was to place the tweeter bezel over the woofer basket, but then Bernie, who has a router, came to my rescue. The bezel is MUCH smaller on my tweeter.

dave

Re round over: it must be at least the diameter of the frequency, so ~13543"_sec/pi/2500 = ~1.72" round over.I am starting to consider rebuilding the baffle. Here is what I am thinking, with a flush mounted tweeter tucked under the woofer flange.

Re dip: often a standing wave/eigenmode (1/2 WL resonance), so ~13543"_sec/2/2500 = ~2.7", ergo your 2.6" in two planes just ~ increases the dip ~1.4142 or 2x (I forget which ATM). 🙁

In short, either a complete box design rethink based on this chart for the tweeter section and/or do like the pioneers did and damp the (entire) baffle in the tweeter area.

- Home

- Loudspeakers

- Multi-Way

- Progress I have made, and advice I am looking for on my current ported two-way design