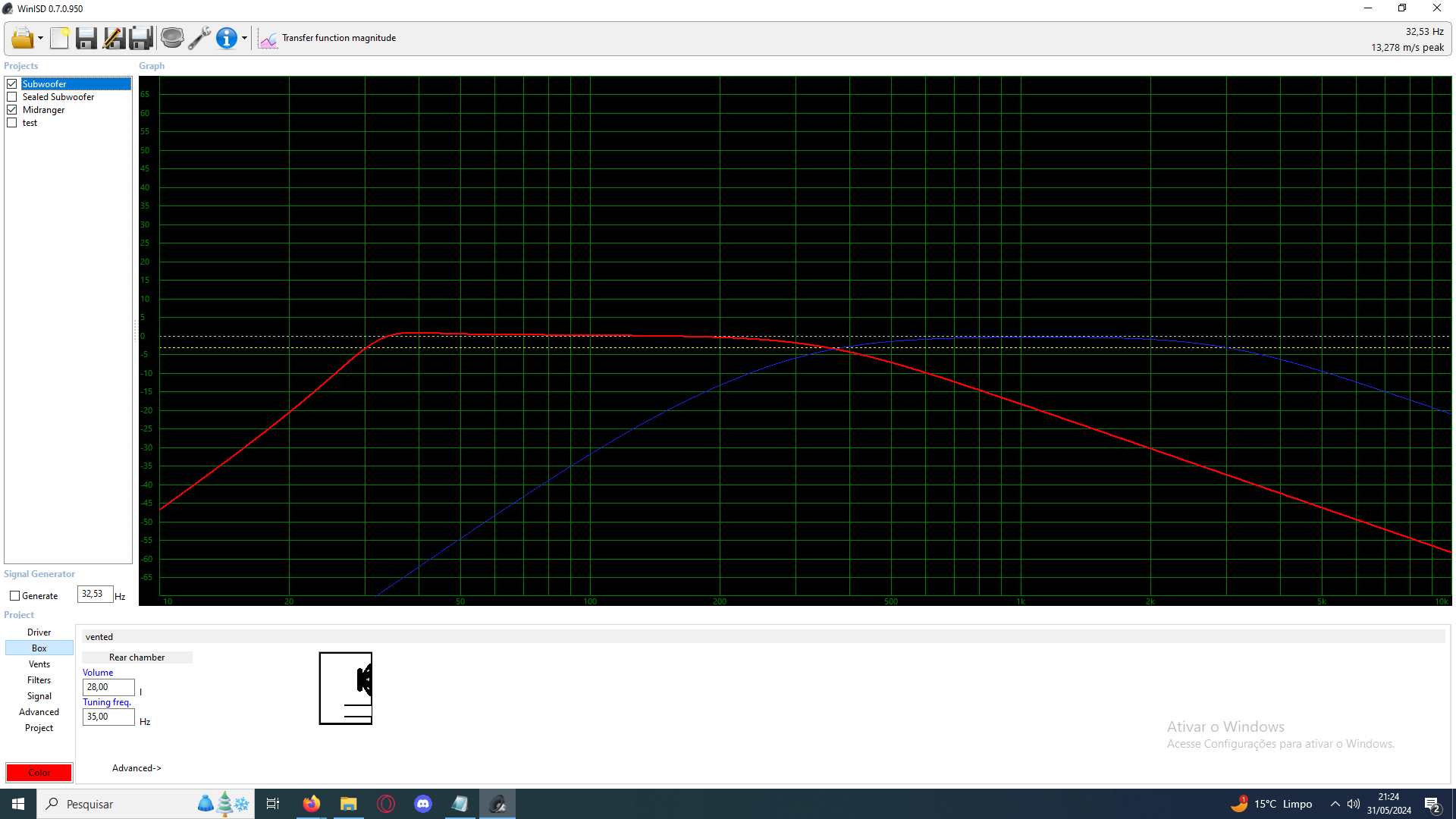

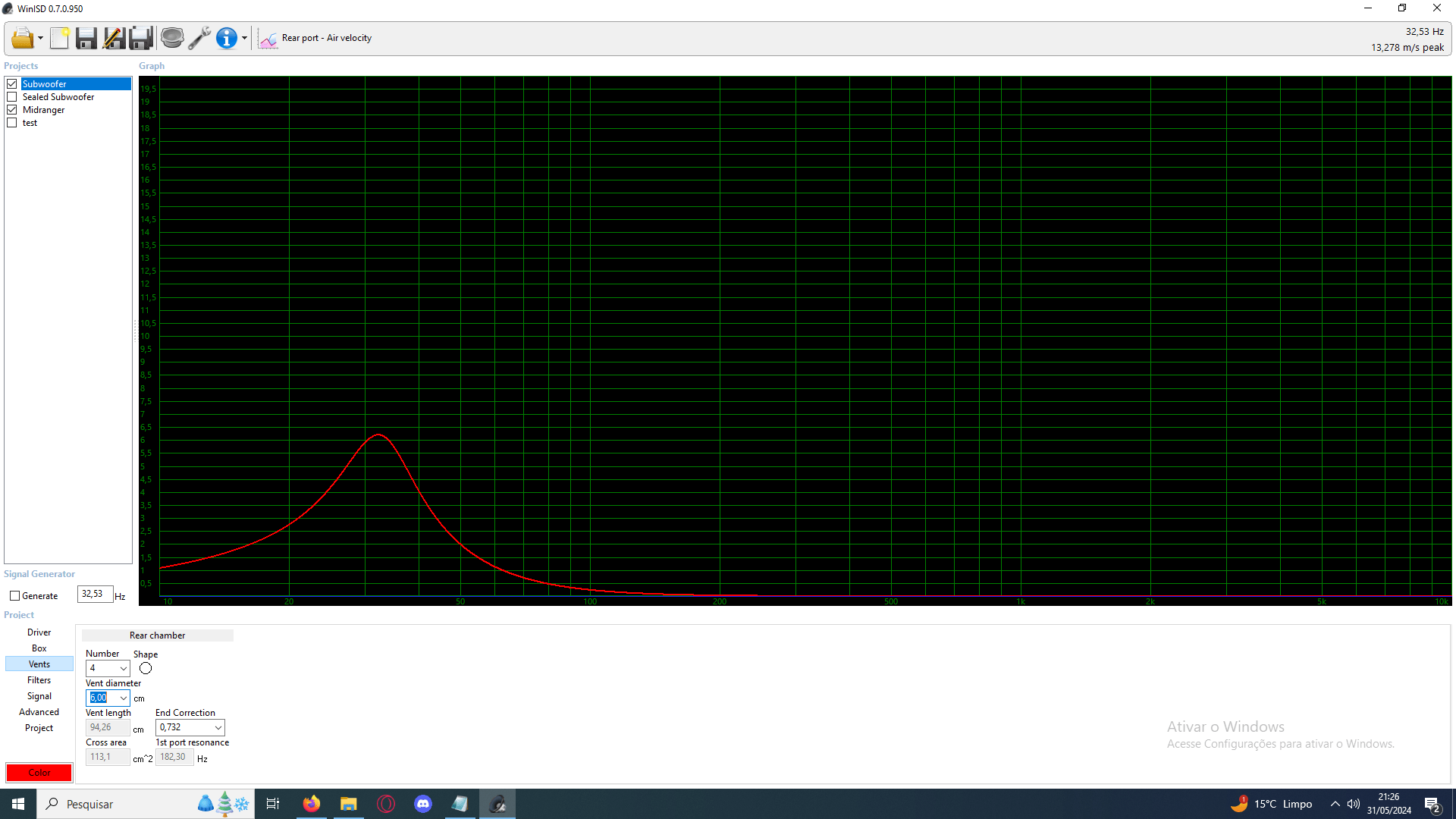

I'm designing a box for an 8" woofer, when I see the air speed graphs in the ducts it's always absurd values and when I fix the duct it's more than a meter in size

What frequency do you recommend for this box? I tried co, 30, 35 and 43.49 Hz

Here are my woofer settings

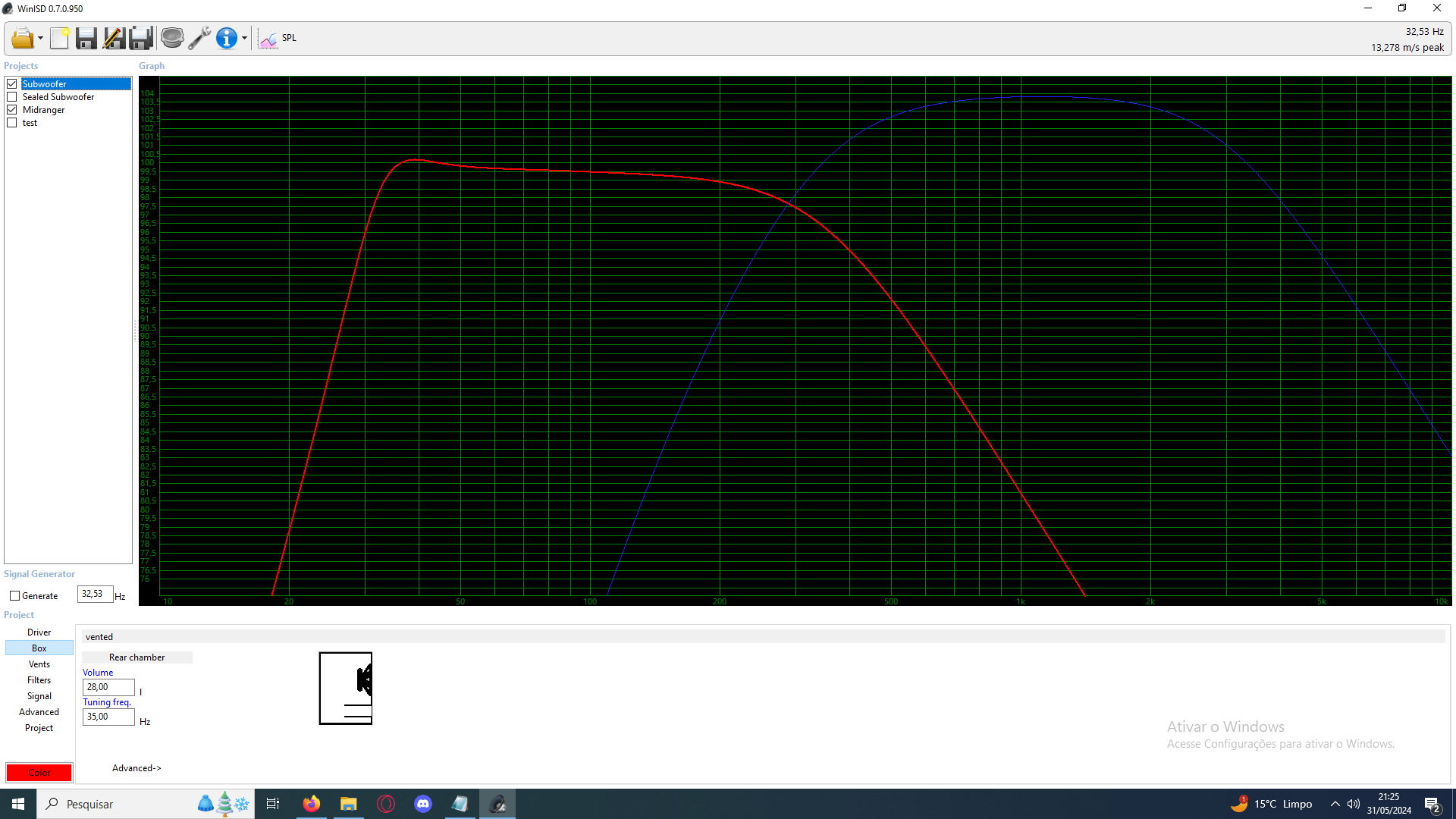

I tried to make it work in a sealed box so the spl disparity between the sealed and ducted box really discouraged me, as the midrange has a very high spl in comparison.

What frequency do you recommend for this box? I tried co, 30, 35 and 43.49 Hz

Here are my woofer settings

I tried to make it work in a sealed box so the spl disparity between the sealed and ducted box really discouraged me, as the midrange has a very high spl in comparison.

Attachments

the huge length results from your decision to use 4 vents, 6 cm diameter each.

Also, the woofer you chose has very low vas, which requires a long port (vent) for low tuning or alternatively a small port diameter. The datasheet suggests one port with 5 cm diameter, which I find rather small!

Increasing the total vent surface leads to longer vents (vent surface/length ratio remains more or less the same).

By the way it's much better to have one (big) vent only, to reduce chuffing noises.

If I remember correctly a rule of thumb for airspeed is max 10% of speed of sound, thus 34 m/s.

But I am currently investigating this matter and don't think air speed is a suitable parameter for vent dimensioning.

If you want to calculate the "ideal" vent diameter have a look at my suggested method:

https://www.diyaudio.com/community/...rbers-and-port-geometries.388264/post-7695977

You can also read about the benefits of port flanges/flares!

Also, the woofer you chose has very low vas, which requires a long port (vent) for low tuning or alternatively a small port diameter. The datasheet suggests one port with 5 cm diameter, which I find rather small!

Increasing the total vent surface leads to longer vents (vent surface/length ratio remains more or less the same).

By the way it's much better to have one (big) vent only, to reduce chuffing noises.

If I remember correctly a rule of thumb for airspeed is max 10% of speed of sound, thus 34 m/s.

But I am currently investigating this matter and don't think air speed is a suitable parameter for vent dimensioning.

If you want to calculate the "ideal" vent diameter have a look at my suggested method:

https://www.diyaudio.com/community/...rbers-and-port-geometries.388264/post-7695977

You can also read about the benefits of port flanges/flares!

Last edited:

Why do they show as different?the spl disparity between the sealed and ducted box

What literage do you suggest? I was trying to keep the air speed lower than 17m/s so the ducts wouldn't blowthe huge length results from your decision to use 4 vents, 6 cm diameter each.

Also, the woofer you chose has very low vas, which requires a long port (vent) for low tuning or alternatively a small port diameter. The datasheet suggests one port with 5 cm diameter, which I find rather small!

Increasing the total vent surface leads to longer vents (vent surface/length ratio remains more or less the same).

By the way it's much better to have one (big) vent only, to reduce chuffing noises.

If I remember correctly a rule of thumb for airspeed is max 10% of speed of sound, thus 34 m/s.

But I am currently investigating this matter and don't think air speed is a suitable parameter for vent dimensioning.

If you want to calculate the "ideal" vent diameter have a look at my suggested method:

https://www.diyaudio.com/community/...rbers-and-port-geometries.388264/post-7695977

You can also read about the benefits of port flanges/flares!

Even if I only put 1 duct it's huge

You'll want to find out why. Are you able to do something about the upper rolloff, it may be interfering?

I don't really understand this, but I can't do anything I don't think, just change the volume of the box and the size of the duct the resonant frequency of the box as wellupper rolloff

Without details I'm concerned others won't be able to help.. but would it not be more direct for you to try using a different box simulator? Whether it's a data entry or a calculation discrepancy, it may come out in the wash..

I didn't expect this problem lol, learning as always, now the challenge is the woofer. On the other hand, which I never mentioned in this forum, I have a 63-liter box for a subwoofer. I don't know if I will be able to use it in the future, the idea was that I wouldn't, but I don't think I will have an exhaust.Without details I'm concerned others won't be able to help.. but would it not be more direct for you to try using a different box simulator? Whether it's a data entry or a calculation discrepancy, it may come out in the wash..

I got a sealed 3-way gradient box with a 10-inch woofer and calculating the entire volume of the box is ±30 liters, I wouldn't think that my 3-way box with an 8-inch woofer would be bigger than that

Usually the sensitivity of the driver is not affected by the inside of the box (the outside of the box is another story, but these simulators do not consider the outside of the box). Filters can also change things.

This is why I'm surprised at your results. It is why a person can normally calculate sealed box volumes in their head and not expect any problems.

This is why I'm surprised at your results. It is why a person can normally calculate sealed box volumes in their head and not expect any problems.

I was looking here and the duct starts blowing when I use the full capacity of the woofer (30w which will be the maximum put into it) I'm following the following logic: Woofer (60-70%): 30W to 35W Midrange (20-30%): 10W to 15W Tweeter (10%): 5W I will apply it in 3 ways, maximum 50w

What literage do you suggest? I was trying to keep the air speed lower than 17m/s so the ducts wouldn't blow

Even if I only put 1 duct it's huge

T/S max flat:

net volume (Vb) (L) = 20*12*0.54^3.3 = 31.4 L

box tuning (Fb) (Hz) = 0.42*43.49*0.54^-0.96 = 33 Hz

dv min. (cm) = ((20*(Sd*Xmax/10)^0.5)/Fb^0.25)/10 = 8.97 cm

L' = 23500/(33^2*31.4) = 0.6872

lv (cm) = (0.6872*8.97^2) - (0.73*8.97) = 48.745 cm

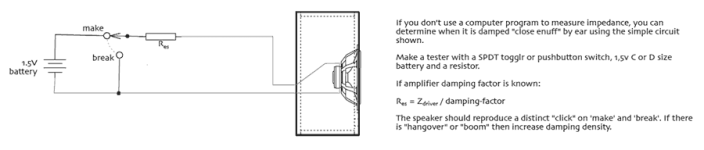

HR calcs ~ 18.77 m/s @ 30 Hz, but 'critically' damping the vent drops it to < 2 m/s!, so the 'name of the game' is build the biggest box, vent you can 'afford' and damp to 'taste' and it 'is what it is'. 😉

Attachments

This tool will help you gain insight in the required diameter and flare:

https://www.subwoofer-builder.com/flare-it.htm

https://www.subwoofer-builder.com/flare-it.htm

Please refer to the corrected version here - just in case:If you want to calculate the "ideal" vent diameter have a look at my suggested method:

https://www.diyaudio.com/community/...rbers-and-port-geometries.388264/post-7695977

https://www.diyaudio.com/community/...rbers-and-port-geometries.388264/post-7697685

T/S max flat:

net volume (Vb) (L) = 20*12*0.54^3.3 = 31.4 L

box tuning (Fb) (Hz) = 0.42*43.49*0.54^-0.96 = 33 Hz

dv min. (cm) = ((20*(Sd*Xmax/10)^0.5)/Fb^0.25)/10 = 8.97 cm

L' = 23500/(33^2*31.4) = 0.6872

lv (cm) = (0.6872*8.97^2) - (0.73*8.97) = 48.745 cm

HR calcs ~ 18.77 m/s @ 30 Hz, but 'critically' damping the vent drops it to < 2 m/s!, so the 'name of the game' is build the biggest box, vent you can 'afford' and damp to 'taste' and it 'is what it is'. 😉

The air speed in the ducts has dropped incredibly but the size itself is huge, there is no way I can put a duct this size on the front of the box, I would have to put it on the top but I don't know if it would make any difference to the sound

- Home

- Design & Build

- Software Tools

- Problems with air speed in ducts (WinISD)