(bold mine). I think (I know, that is) it's the other way 'round. Don't parallel low ESR caps with more than 10:1 capacitance ratio (assuming increased ESL from the bigger packaged ones).I've found that with reasonably closely spaced surface mount decoupling caps, if the paralleled values are in the ratio of 10:1 or greater, the resonance between caps is minimal. I didn't invent that, I got it from an old app note somewhere, but it does work in practice.

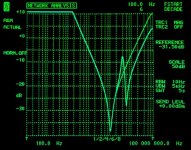

Only way to really know if you are safe or not when paralleling low ESR caps is either an in-situ network analyser plot or a close look at a bell-ringer time response, in-situ as well. Otherwise stick with a high-ESR tant/'lytic plus a single low-ESR film/ceramic.

(bold mine). I think (I know, that is) it's the other way 'round. Don't parallel low ESR caps with more than 10:1 capacitance ratio (assuming increased ESL from the bigger packaged ones).

Only way to really know if you are safe or not when paralleling low ESR caps is either an in-situ network analyser plot or a close look at a bell-ringer time response, in-situ as well. Otherwise stick with a high-ESR tant/'lytic plus a single low-ESR film/ceramic.

The caps I normally use are all quite small, generally 0402 and 0603, 0805 at the largest. I've encountered no problems following the 10:1 rule, and yes it has been examined with an oscilloscope and spectrum analyzer, as I do this sort of thing for a living. It has also been simulated using Genesys. YMMV, and all that.

Last edited:

Yep, the trick is that the inductive slope of the large one is swamped out by the ESR (or additional external R) so that it cannot create a problem at the intersect with the capacitive slope of the smaller cap. Reminds me about opamp compensation, more than 20dB/dec slope difference at Aol 1/beta intersect --> potential problem.If the larger cap is somewhat lossy, as a tantalum or aluminum electrolytic would be, this resonance is damped.

No doubt here, as with same ballbark inductance the resonances are only apart by a factor of 3 or 4, problems start at 10x++. My comment was more like when people try to bypass one bigger "audio grade" THT film, notably with axial leads, with something too small (both capacitance and ESL).The caps I normally use are all quite small, generally 0402 and 0603, 0805 at the largest. I've encountered no problems following the 10:1 rule, and yes it has been examined with an oscilloscope and spectrum analyzer, as I do this sort of thing for a living. It has also been simulated using Genesys. YMMV, and all that.

No doubt here, as with same ballbark inductance the resonances are only apart by a factor of 3 or 4, problems start at 10x++. My comment was more like when people try to bypass one bigger "audio grade" THT film, notably with axial leads, with something too small (both capacitance and ESL).

Ah well; as I said I would never use leaded parts for bypass with high speed devices. It's just asking for trouble.

Tin,

the resistor view is valid.

It;s the resistance that does the snubbing.

Similarly it's the ESR that does the snubbing, if there is the correct amount of it.

So does that mean all the money i have been spending on buying high quality polypropylenes is wasted, that i might as well have stuck to using a high esr al electrolytic all along, potentially better.

If a higher esr cap is better why use ceramics when al electros are more commonly available and in a wider range of values.

No context means no comment.

However, it is certainly true that some purchases of 'high quality' capacitors for audio use are a waste of money. Some may be worse than that; the 'high quality' capacitor might actually be a worse fit for a particular circuit duty than a perfectly ordinary cheap component. Good engineering is the answer.

However, it is certainly true that some purchases of 'high quality' capacitors for audio use are a waste of money. Some may be worse than that; the 'high quality' capacitor might actually be a worse fit for a particular circuit duty than a perfectly ordinary cheap component. Good engineering is the answer.

If a higher esr cap is better why use ceramics when al electros are more commonly available and in a wider range of values.

Ceramics are smaller and they don't wear out, so for some applications where you don't need large capacitance, a ceramic is a better idea than an electrolytic. Because they are physically smaller, they will also have a higher self resonant frequency, making them a better fit for some types of supply bypassing.

High ESR is better when the circuit calls for high ESR; elsewhere high ESR may be a problem or it may not be a problem.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Power Supplies

- Power supply bypass capacitor types