It's interesting that you are thinking of not letting the metal of the choke touch the can. I'm thinking about potting a power transformer later on this year, which would be my first time doing this. My idea was to let the metal of the transformer touch the can, so that it'll have a better heat transfer. Maybe even use some thermal paste.

Is there anyone here with previous experience who can tell us the pro's and cons of having the transformer touch or not touch the metal of the can? I'm curious which route I should take.

Is there anyone here with previous experience who can tell us the pro's and cons of having the transformer touch or not touch the metal of the can? I'm curious which route I should take.

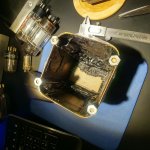

I just found a video I'd seen a few years before (most likely linked to on diyaudio) on building McIntosh amps. At three minutes they show potting the transformer. It appears to lay centered on the plastic bobbin so that the laminations don't touch the outer case, then it's filled with "hot black tar."

YouTube

Other similar-looking videos also come up from this Youtube search string, but I haven't watched them:

YouTube

For an experiment you could put a temperature sensor on the laminations, pot the transformer with the laminations away from the edge of the can, and check the temperature rise versus the outside of the can.

YouTube

Other similar-looking videos also come up from this Youtube search string, but I haven't watched them:

YouTube

For an experiment you could put a temperature sensor on the laminations, pot the transformer with the laminations away from the edge of the can, and check the temperature rise versus the outside of the can.