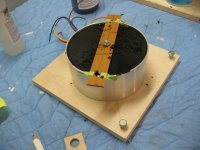

A few weeks ago I received the two 1 kVA Avel Lindberg toroid transformers for a pair of monoblocks I'm building. I was hoping to find ready-made drawn metal cans in which they could be potted. There was one manufacturer that sourced such cans, but there was a considerable tooling charge plus a rather high per unit cost. While there were many such enclosures listed on Ebay, none were sufficiently wide. So I decided to fabricate enclosures in my shop. The vertical sections consisted of 3.25" x 7" OD x 0.125" wall thickness 6061 Al tube, while the top was fabricated from 0.125" 6061 sheet. The 7" tube presented a challenge to hold in the jaws of my lathe chuck, and I ended up having to grab the tube from the inside. I wanted the top covers to not have any tooling holes, so I bandsawed the covers approx 1/8" oversize and glued them onto a plywood base that was bolted to the lathe faceplate. That worked fine, but ungluing the finished Al cover proved a challenge, requiring a torch to soften the glue. The tube and Al disk were then glued together and put back on the lathe for a finishing pass. Three holes were drilled near the bottom of the tube section to accommodate grommets for wire egress, and then the grommets were then filled with silicone adhesive to prevent any potting material from leaking.

The inverted enclosures were placed on a level table (3 bolts on a 12x12" piece of plywood were used to make the leveling surface), The center of the transformer has a micarta insert that provides more reliable thread holding than tapping into the epoxy. For potting compound I selected Epic MPC epoxy which has a very long cure time permitting deep pour depths without the problem of a runaway exothermic reaction. I found the compound difficult to get a consistent cure even when carefully following the provided instructions. However, after a week the epoxy finally hardened. The final step was to cover the enclosure bottom with a thin self adhesive sponge rubber sheet.

The next step will be getting the PCBs back and starting to wire things up.

The inverted enclosures were placed on a level table (3 bolts on a 12x12" piece of plywood were used to make the leveling surface), The center of the transformer has a micarta insert that provides more reliable thread holding than tapping into the epoxy. For potting compound I selected Epic MPC epoxy which has a very long cure time permitting deep pour depths without the problem of a runaway exothermic reaction. I found the compound difficult to get a consistent cure even when carefully following the provided instructions. However, after a week the epoxy finally hardened. The final step was to cover the enclosure bottom with a thin self adhesive sponge rubber sheet.

The next step will be getting the PCBs back and starting to wire things up.

Attachments

Looks good for sure, where did you get the tubes from?

Can you share some prices? Tools you needed for this?

Epoxy name?

Thanks

Can you share some prices? Tools you needed for this?

Epoxy name?

Thanks

On Tuesdays it's Senior discount day at Goodwill's, so scan the shelves for pots and pans.I was hoping to find ready-made drawn metal cans in which they could be potted.

Yours look fantastic! I hope you're not hiding them in that chassis?

Pots and pans. Very good reuse when it can work. I support the thinking but also know that to get a pair of anything is a challenge. I will remember that in the future though.

Man, a machine shop. I was telling my wife today that if I had such a shop, I would be in there a LOT. Pipes are uncanny, pun intended. FWIW, I used to make irrigation pipe from aluminum anywhere from 6" to 12" diameter. There is more to it than people think.

Man, a machine shop. I was telling my wife today that if I had such a shop, I would be in there a LOT. Pipes are uncanny, pun intended. FWIW, I used to make irrigation pipe from aluminum anywhere from 6" to 12" diameter. There is more to it than people think.

For those intersted in ready made covers that could also be potted, check out AnTek Inc at https://www.antekinc.com

Maybe slightly smaller than what the OP needed for 1 kVA, but there are sizes for toroids up to about 500 VA.

They're in the MISC section under Covers and Mounting on the site.

I've bought and been happy with several of their transformers, but have't tried the covers as I have never felt the need.

Just passing on the info for those who might.

Maybe slightly smaller than what the OP needed for 1 kVA, but there are sizes for toroids up to about 500 VA.

They're in the MISC section under Covers and Mounting on the site.

I've bought and been happy with several of their transformers, but have't tried the covers as I have never felt the need.

Just passing on the info for those who might.

The epoxy I used was Epic MPC epoxy. You can Google it, and there is a good description on their website. Regarding sources for Al tube and sheet, I recommend https://www.onlinemetals.com/. They have a wide range of tube diameters and sheet thicknesses at reasonable cost. If the transformers I selected were of a smaller diameter then AnTek enclosures would be one way to go. Regarding Al pots, I could not find anything of the correct dimensions, but that was one of the first places I investigated.

In a future post I will describe the building of the chassis. No prefabricated chassis of desired dimensions were available, so I built the chassis from scratch. My tools include a metal engine lathe, a vertical mill, a table saw, and a bandsaw. The machine shop tools are a leftover from my previous project: plans building an F8L Falco aircraft, but that is another story.

In a future post I will describe the building of the chassis. No prefabricated chassis of desired dimensions were available, so I built the chassis from scratch. My tools include a metal engine lathe, a vertical mill, a table saw, and a bandsaw. The machine shop tools are a leftover from my previous project: plans building an F8L Falco aircraft, but that is another story.

Good stuff, familiar area. Make sure to derate the transformer though and test and measure the temperature under load.

Clever to use grommets and pull the cabling through those at the sides. Many industrial potted transformers have the wires sticking out of the epoxy.

Clever to use grommets and pull the cabling through those at the sides. Many industrial potted transformers have the wires sticking out of the epoxy.

- Home

- Design & Build

- Construction Tips

- Potting Large Toroid Transformers