My half-educated guess is that the quality of caps depends on the foil type, construction type, homogenity of the foil thickness, and winding tightness technology.

For the polystyrene cap era, it's very likely that the sota winding machinery was of German manufacture.

Explains why top notch Styrene caps from the late '70s till halfway the '90s were predominantly North Eurica production; ITT, MIAL, Phily, Siemens.

The KS caps i measured are commonly way more accurate than their nominal +/- 1% spread, higher voltage Polystyrene caps could also be special ordered with 1% accuracy.

A diyA member also measured one of the boxed Phily caps : Measured Differences Between Capacitors for Audio Applications

The most striking about the Greeny Russians (apart from dimensions) is the giant spread in accuracy, 0.5% to 5%.

Dirt cheap though, for someone with a use for bulky 250V caps.

For the polystyrene cap era, it's very likely that the sota winding machinery was of German manufacture.

Explains why top notch Styrene caps from the late '70s till halfway the '90s were predominantly North Eurica production; ITT, MIAL, Phily, Siemens.

The KS caps i measured are commonly way more accurate than their nominal +/- 1% spread, higher voltage Polystyrene caps could also be special ordered with 1% accuracy.

A diyA member also measured one of the boxed Phily caps : Measured Differences Between Capacitors for Audio Applications

The most striking about the Greeny Russians (apart from dimensions) is the giant spread in accuracy, 0.5% to 5%.

Dirt cheap though, for someone with a use for bulky 250V caps.

Last edited:

The very best capacitors for this type of job are the original ERO capacitors from Germany. Especially the MKP1837's and MKT1822's. The new production Vishay/Roederstein are not as good. Luckily, you can find just about any value of the original NOS EROs on eBay for pennies.

I have my serious moments (not often though).

Odd part about Mr Hoffman's page is that 600V AuraT caps are specced at 5%, btw.

Odd part about Mr Hoffman's page is that 600V AuraT caps are specced at 5%, btw.

The most striking about the Greeny Russians (apart from dimensions) is the giant spread in accuracy, 0.5% to 5%.

Dirt cheap though, for someone with a use for bulky 250V caps.

I'm looking for alternatives to the Panasonic ECQP range for my Orion ASP upgrade and it seems Digikey is running out of these ( at least the 1% types i want )....🙁

...seems they were discontinued June 2008....so stocks are going.

Last edited:

One for Jaco, as he seems to be Mr. Polystyrene. I picked up some little orange Siemens box-style polystyrenes (at least they say "KS" on them), with the leads in the corners. It looks like the type may be GSE. Sound familiar? Also picked up in the same run were some more of the Mial red box-style caps, and a handful of Rifa PHE307 polycarbonates. The Rifas are very well-made with very neat and heavy zinc spray at the ends with the leads buried securely therein. I may use them for that "warm and cozy" polycarbonate sound.

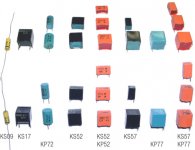

Here you go.

(i own 15000 of the orange KS fellas, so i likely rank Mr Poly)

(i've got a headache from driving 100 miles through snow, is the pits with an unstable neck, 02.17am here, hence the swift response)

(i own 15000 of the orange KS fellas, so i likely rank Mr Poly)

(i've got a headache from driving 100 miles through snow, is the pits with an unstable neck, 02.17am here, hence the swift response)

Attachments

Last edited:

Thanks for the pics - a help to cap scroungers everywhere... Mine look a trifle different. They just have the value and tolerance printed on the top, with the Siemens logo on the side and KS 63V ,and GSE 01.85.

The local surplus stores have a surprising wealth of good polystyrene and polypropylene caps, perhaps due to the modem and telecom companies in the area. If I get a little spare time (HA!) I should compile a little menengerie of parts. I also have some interesting little bluish-silver Roederstein radial caps with laid-in (though rather thick) leads - you can even see the little hollow in the center as a result of the manufacturing process. I suspect these aren't the best caps in the universe, but they're certainly compact.

The local surplus stores have a surprising wealth of good polystyrene and polypropylene caps, perhaps due to the modem and telecom companies in the area. If I get a little spare time (HA!) I should compile a little menengerie of parts. I also have some interesting little bluish-silver Roederstein radial caps with laid-in (though rather thick) leads - you can even see the little hollow in the center as a result of the manufacturing process. I suspect these aren't the best caps in the universe, but they're certainly compact.

On closer perusal, the Siemens caps look like the smaller members of the KS57 series caps in the picture.

If I collect enough cool and colorful caps, I can color-coordinate them. I have two "citrus series" of RIAA amps at present, one "oranges and lemons" preamp with big yellow polypropylenes and some bright orange BC MKPs, and a "lemon-lime" preamp with the same yellow polypropylenes and the green Russian polystyrenes.

If I collect enough cool and colorful caps, I can color-coordinate them. I have two "citrus series" of RIAA amps at present, one "oranges and lemons" preamp with big yellow polypropylenes and some bright orange BC MKPs, and a "lemon-lime" preamp with the same yellow polypropylenes and the green Russian polystyrenes.

GSE points to the manufacturing date (pff, German gründlichkeit)

The KS series were manufactured till 1995/6.

Official Siemens code is a B series number, B31521 in the early 80s, B31531 from late 80s. (i'm a number mental image fool)

Both series and cap value determine the shape of the box.

Late series caps were labelled S+M (cooperation between Siemens and Matsushita) , i'll post an image tomorrow.

I have a hickload of the black ones too, ITT manufacture, a diyA member offered to help me to a stash of Yellow Phily KS cubes in a range of values. Life can be good.

The KS series were manufactured till 1995/6.

Official Siemens code is a B series number, B31521 in the early 80s, B31531 from late 80s. (i'm a number mental image fool)

Both series and cap value determine the shape of the box.

Late series caps were labelled S+M (cooperation between Siemens and Matsushita) , i'll post an image tomorrow.

I have a hickload of the black ones too, ITT manufacture, a diyA member offered to help me to a stash of Yellow Phily KS cubes in a range of values. Life can be good.

Last edited:

I tried the Russian 100n/250V K71 Polystyrols in RIAA. Shunt Cascode ECC189 architecture.

I did not like them - the bass really suffered, even after long running-in. I put back my ultra-high quality micas (made by TAB) and left them there.

I tried the ССГ micas too, in combination with K71. Still no good.

I did not like them - the bass really suffered, even after long running-in. I put back my ultra-high quality micas (made by TAB) and left them there.

I tried the ССГ micas too, in combination with K71. Still no good.

Jaco, my Siemens caps are earlier production than that. I hadn't noticed them before at my local surplus place - maybe they were recent acquisitions for some newly defunct company or someone clearing their stockroom of obsolete material. Anyway, I grabbed a couple of bags. 1n2 is a good value to have for crossover frequencies ~5-6k. I might grab the rest when I go back.

Who cares, i have them from late '70s to late '90s production.

Makes no difference to me, these parts virtually last forever, long term stability of polystyrene is top notch and i measure components just the same.

I've awaited superior low-value capacitors since the late '80s, there's been talk about poly-ethylene norbornene caps since the early '90s and still no go, at the current "Out-CD'd" price levels it's a waste not to grab some.

Makes no difference to me, these parts virtually last forever, long term stability of polystyrene is top notch and i measure components just the same.

I've awaited superior low-value capacitors since the late '80s, there's been talk about poly-ethylene norbornene caps since the early '90s and still no go, at the current "Out-CD'd" price levels it's a waste not to grab some.

Last edited:

Jaco, I don't really care about the date either, it's just noted in passing. The caps I bought were in lots of 50 in their original poly bags - they must have been sitting in someone's stockroom for a while. I paid 30 cents apiece.

Having said that, I've noticed that some of the crummy laid-in lead type polystyrenes tend to craze a bit on the outside as they age, and that's not nice...

Having said that, I've noticed that some of the crummy laid-in lead type polystyrenes tend to craze a bit on the outside as they age, and that's not nice...

Defibrillator capacitors would be grand

Ah, i just remember i shack/shag with one of those >1/4m$ medical chicks

Siemens KS, I love them 🙂

http://www.diyaudio.com/forums/analogue-source/165603-balanced-input-all-dc-coupled-riaa-preamp.html

Regards,

Frans.

http://www.diyaudio.com/forums/analogue-source/165603-balanced-input-all-dc-coupled-riaa-preamp.html

Regards,

Frans.

Hello

I know this thread is old but the question I will ask might be interesting for others. The question was asked before but sadly not answered.

What exactly are polystyrene extended foil capacitors? What is the difference between extended and normal foil polystyrene's? Would be really nice to get a detailed description of the construction of extended foil polystyrene capacitors.

Are they always superior to normal polystyrene capacitor or do they have also disadvantages? And finally how can we identify them? Are all box type polystyrene's extended foil polystyrene's?

Sorry for all those questions, but as mentioned before, the answers could also interesting for other members.

Kind Regards

Phil

I know this thread is old but the question I will ask might be interesting for others. The question was asked before but sadly not answered.

What exactly are polystyrene extended foil capacitors? What is the difference between extended and normal foil polystyrene's? Would be really nice to get a detailed description of the construction of extended foil polystyrene capacitors.

Are they always superior to normal polystyrene capacitor or do they have also disadvantages? And finally how can we identify them? Are all box type polystyrene's extended foil polystyrene's?

Sorry for all those questions, but as mentioned before, the answers could also interesting for other members.

Kind Regards

Phil

What is the difference between extended and normal foil polystyrene's?

Extended foil types are wrapped with foil #1 extending out of one end, and foil #2 extending out of the other end.

Then each end is pressed together and connected to the leads by spraying, welding, or other methods.

Because all the turns of either foil are shorted together, the inductance is much reduced, since all the

turns are then in parallel instead of in series. This can be done with any type of film.

http://www.sbelectronics.com/wp-content/uploads/2012/06/metallized_film_capacitor_illustrations1.pdf

Last edited:

- Status

- Not open for further replies.

- Home

- Source & Line

- Analog Line Level

- Polystyrene Caps For Filters