I dug up a pair of ERO MKC capacitors, with the correct values, for an amplifier I am considering building.

I am NOT familiar with polycarbonate, nor have I ever used it before.

Are there any opinions. pro and con, as to the use of polycarbonate? 😕

THANKS and y'all have a great 4th of July!

Steve

I am NOT familiar with polycarbonate, nor have I ever used it before.

Are there any opinions. pro and con, as to the use of polycarbonate? 😕

THANKS and y'all have a great 4th of July!

Steve

It's one of many suitable polymers for coupling caps. There was probably a time in recent audiophile history when it was considered a ne plus ultra upgrade.

John

John

MKC-Caps are among the best considering temperature drift. But dielectric absorption is worse than MKP. But in the AF Range this is completely regardless. There are much, really much worse dielectrics like paper in oil, wax etc.

There is no problem using these MKC's. They'll work fine.

There is no problem using these MKC's. They'll work fine.

Is it true what is said about caps with polar dielectrics working best with a relatively high DC voltage across them?

the polycarbonate film of the type used for capacitor production became obsolete (they for whatever reason stopped making it).

As a result polycarbonate capacitors became obsolete. They were among the best available at reasonable cost. Far cheaper than Polypropylene at that time (80's to 90's) and yet almost as good. Far better than any of the MKT and MKS that have been used since.

I would not be surprised to hear that a few specialist cap manufacturers are still making polycarbonate capacitors but using old stock film or unsuitable film for current production. Be careful buying "new" polycarbonate capacitors.

As a result polycarbonate capacitors became obsolete. They were among the best available at reasonable cost. Far cheaper than Polypropylene at that time (80's to 90's) and yet almost as good. Far better than any of the MKT and MKS that have been used since.

I would not be surprised to hear that a few specialist cap manufacturers are still making polycarbonate capacitors but using old stock film or unsuitable film for current production. Be careful buying "new" polycarbonate capacitors.

Last edited:

Polycarbonate has been largely replaced by polyphenylene sulfide which has the same operating temperature range but lower dissipation factor and higher insulation resistance.

John

John

Polycarbonate has been largely replaced by polyphenylene sulfide which has the same operating temperature range but lower dissipation factor and higher insulation resistance.

John

Polyphenylene sulfide caps are available as surface mount. You can stack a bunch of 'em and get 10u in a wee bit of real estate.

Polycarbonates are great for timing and sample/hold.

The late Bob Pease had a great cap treatise which is on National Semi's website.

the polycarbonate film of the type used for capacitor production became obsolete (they for whatever reason stopped making it).

Pure and simple.......Environmental reasons. However all this environmental protection stuff is a hyprocrisy as Tants continue to be used by the million in mobile phones....

Note of caution.....I recently repaired a tube amp which had a polycarbonate cap across the mains input and oozed.....NO!! they aren't reliable in this application. polycarbonate caps aren't suitable as X rated.

richy

Environmental reasons? That doesn't make much sense to me since PC is still made by the metric ton and used for about a bazillion other things and is commodity priced.

Teflon is far less eco-friendly to manufacture.

Teflon is far less eco-friendly to manufacture.

Environmental reasons? That doesn't make much sense to me since PC is still made by the metric ton and used for about a bazillion other things and is commodity priced.

Teflon is far less eco-friendly to manufacture.

I share your absurdity. Here in EU one won't be suprised by the so called Eco cleansing nutters. If these people (if one can call then this) are getting their way, they will ban all.

Last edited:

Only X rated caps are suitable for X rated duty !

I was a bit short on the previous comment......I should have mentioned that some decades ago there was a belief that caps rated for 1kV DC could be adequate strapped across the AC mains supply. No don't do it !

Some modern caps are mentioned with dual AC & DC ratings i.e several in Farnell cat and others....... take heed.

richy

What function do caps strapped across the mains perform? I have some MKT X2 rated at 275V AC and was wondering if I can use them at 350 DC to bypass lytics in the PS. There's no DC rating written on the cap.

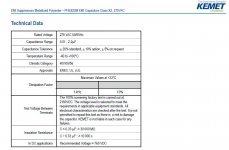

Have a look at the datasheet...this one is only an example...Read carefully lower parts, but NOTE: Depending on manufacturer,  NOT all vendors produce AC rated caps have sim ratings for DC....it varies from one to the other, and check product datasheets.

NOT all vendors produce AC rated caps have sim ratings for DC....it varies from one to the other, and check product datasheets.

Not my responsibility if one gets injured and premises burns down !

Richy

NOT all vendors produce AC rated caps have sim ratings for DC....it varies from one to the other, and check product datasheets.

NOT all vendors produce AC rated caps have sim ratings for DC....it varies from one to the other, and check product datasheets. Not my responsibility if one gets injured and premises burns down !

Richy

Attachments

reasons?

Supply and demand, polycarbonate caps were not that cheap.

(e.g. $9 for a 10uF/63V axial Roederstein MKC1860 overhere, in 1990)

Another cold war would be nice (or a hot one, whatever the preference)

Well, the PC films were generally made with a solvent casting process. Methylene chloride is the usual solvent and that's been frowned upon. However, the solvent recovery in the process is exceedingly high (it has to be in order for it to be economical). If the problem is regulatory, I could see why someone would get out of that niche biz rather than invest a lot of R&D (and accept higher costs) by moving to another solvent system.

PC resin is still widely available if someone wanted to set the process up in a different part of the world. And QS's links indicate that some folks have done just that.

PC resin is still widely available if someone wanted to set the process up in a different part of the world. And QS's links indicate that some folks have done just that.

Well we have some well informed guys here.

As stated above Polycarbonate was withdrawn from market for environmental reasons - before that happened it was the dielectric of choice for stable timing, audio and and filter circuits and the like. I designed them into a heap of stuff in the day job back in the late 1990's. They were almost as good as Polypropylene but were physically smaller for teh same Capacitance Value/Voltage Rating etc.

As also stated above PolyCarbonate was replaced by Polyphenylene Sulphide (PPS).

If the 400V maximum rating of most PPS Caps is adequate in your amplifier then I HIGHLY RECOMMEND PPS caps. They are great in audio circuits, at least as good as Polyproplylene and slightly better than the PolyCarbonate. PPS actually has a better temperature rating than most other caps (140 degrees C).

My SS Phono Pre is full of PolyCarbonate caps.

My SS Power Amp uses PolyCarbonate as the "base charge" suck out caps on the output transistors.

An early Baby Huey used PolyCarbonate coupling caps to the EL84 Output Tubes.

Cheers,

Ian

As stated above Polycarbonate was withdrawn from market for environmental reasons - before that happened it was the dielectric of choice for stable timing, audio and and filter circuits and the like. I designed them into a heap of stuff in the day job back in the late 1990's. They were almost as good as Polypropylene but were physically smaller for teh same Capacitance Value/Voltage Rating etc.

As also stated above PolyCarbonate was replaced by Polyphenylene Sulphide (PPS).

If the 400V maximum rating of most PPS Caps is adequate in your amplifier then I HIGHLY RECOMMEND PPS caps. They are great in audio circuits, at least as good as Polyproplylene and slightly better than the PolyCarbonate. PPS actually has a better temperature rating than most other caps (140 degrees C).

My SS Phono Pre is full of PolyCarbonate caps.

My SS Power Amp uses PolyCarbonate as the "base charge" suck out caps on the output transistors.

An early Baby Huey used PolyCarbonate coupling caps to the EL84 Output Tubes.

Cheers,

Ian

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- Polycarbonate as coupling caps?