Some years ago Wim published his turntable project in this forum (DIY Automated rotary table for automatic polar measurements - diyAudio).

We picked up Wim’s design goals

1) make a complete polar measurement with 1 mouse click

2) table must be strong enough to carry heavy speakers (min 50kg)

3) it must be DIY

and added some more

4) should be able to communicate with ARTA (to realize 1))

5) easy to build, even for people without electronic skills

Thanks Wim (PIC Software), Dougie (USB Controller) and last but not least Ivo (additional ARTA turntable feature with data export) the turntable project is now finished.

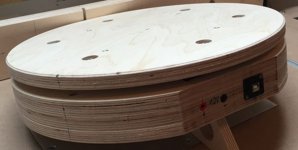

The turntable has passed the first test in the lab with good results (fig 1: turntable with heavy load (60Kg))

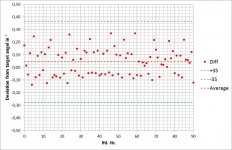

A 360° measurement with 5° resolution will last roundabout 300 seconds (inclusive export of frd-files). The accuracy and the reproducibility are sufficient. Deviation from target angle is < +/- 0.5 degrees (fig 2: reproducibility).

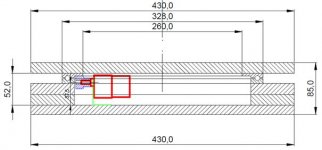

The concept of the turntable is very simple

(fig 3: turntable, drawing).

What is needed:

Some more details could be found in the following papers (sorry, at the moment just in german language).

Kind Regards

Heinrich

We picked up Wim’s design goals

1) make a complete polar measurement with 1 mouse click

2) table must be strong enough to carry heavy speakers (min 50kg)

3) it must be DIY

and added some more

4) should be able to communicate with ARTA (to realize 1))

5) easy to build, even for people without electronic skills

Thanks Wim (PIC Software), Dougie (USB Controller) and last but not least Ivo (additional ARTA turntable feature with data export) the turntable project is now finished.

The turntable has passed the first test in the lab with good results (fig 1: turntable with heavy load (60Kg))

A 360° measurement with 5° resolution will last roundabout 300 seconds (inclusive export of frd-files). The accuracy and the reproducibility are sufficient. Deviation from target angle is < +/- 0.5 degrees (fig 2: reproducibility).

The concept of the turntable is very simple

(fig 3: turntable, drawing).

What is needed:

- ball bearing with gear rim >>> Drehkranz Alu-Druckguss 330 mm verzinkt | Alu-Druckguss | Drehkränze | Hefter Fertigungstechnik

- pinion >>> Artikel 21801100 - Stirnzahnrad aus Stahl mit Nabe Modul 1,5 11 Zähne Zahnbreite 15mm Außendurchmesser 19,5mm

- motor with Encoder >>> https://nodna.de/Metal-Gearmotor-12VDC-with-64-CPR-Encoder-80rpm-6mm-Axis or https://nodna.de/Gear-Motor-12V-84Kg-cm-28rpm-139-1-with-encoder

- USB controller ARTA Turntable

- 4 pieces of 18 mm multiplex Wood

- Various small parts (screws etc.)

Some more details could be found in the following papers (sorry, at the moment just in german language).

Kind Regards

Heinrich

Attachments

Last edited:

.. some additional pictures:

1) Turntable, small

2) ARTA turntable Menu

3) Turntable small + jig for horizontal measurement

4) Menu turntable, manual operation without ARTA

5) Menu, parameters for Operation

6) Turntable with heavy loudspeaker

7) Parts needed

More Information here: ARTA Turntable

Perfect tool in combination with VirtuixCAD: Software

Regards

Heinrich

1) Turntable, small

2) ARTA turntable Menu

3) Turntable small + jig for horizontal measurement

4) Menu turntable, manual operation without ARTA

5) Menu, parameters for Operation

6) Turntable with heavy loudspeaker

7) Parts needed

More Information here: ARTA Turntable

Perfect tool in combination with VirtuixCAD: Software

Regards

Heinrich

Attachments

Nice work, Ente!

Sure beats walking over to the speaker and moving it 5 degrees, then back to the computer 71 times...

Art

Sure beats walking over to the speaker and moving it 5 degrees, then back to the computer 71 times...

Art

Youtube ARTA Turntable

... here you will find some more information about the turntable:

https://www.youtube.com/watch?v=FWQudBXWUZs

Regards

Heinrich

... here you will find some more information about the turntable:

https://www.youtube.com/watch?v=FWQudBXWUZs

Regards

Heinrich

This is a long shot - I'm developing my own rotating turntable for ARTA using an Arduino interface. I chose arduino because it can easily control stepper motors and other sensors needed for homing.

I was wondering if you could let me know how you got ARTA to talk to the turntable? I see that ARTA asks for an .exe for a program which drives the turntable, but how would I make a program which ARTA can use?

I am producing this turntable in the hopes that others find it useful. I am designing it to use off-the-shelf hardware, and the wooden components will be shared as 3D files enabling anyone to get them cut on a CNC.

I was wondering if you could let me know how you got ARTA to talk to the turntable? I see that ARTA asks for an .exe for a program which drives the turntable, but how would I make a program which ARTA can use?

I am producing this turntable in the hopes that others find it useful. I am designing it to use off-the-shelf hardware, and the wooden components will be shared as 3D files enabling anyone to get them cut on a CNC.

This is a typical case of RTFM: http://www.artalabs.hr/download/arta-user-manual.pdf see page 23. You’ll just need to hack an executable that can communicate with your arduino to instruct the table what to do

4real, I have read everything on the arta website and somehow I missed that. Seems simple enough. Thank you for pointing that out.

It was the second hit on Google when looking for "arta turntable" 😉 Sometimes it can really be that easy

Has anyone in NA made this ARTA turntable?

English instructions would be nice as would part number of components that can be sourced on this side of the pond.

Thank you,

David.

English instructions would be nice as would part number of components that can be sourced on this side of the pond.

Thank you,

David.

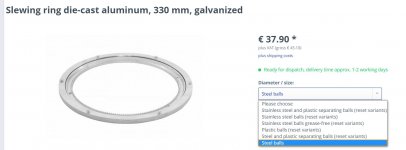

Is this the correct slewing ring?

Is it steel balls that I should be getting?

How about the type of holes?

Do you know of a supplier in North America who can provide such a ring or does it have to be ordered from Germany?

Is it steel balls that I should be getting?

How about the type of holes?

Do you know of a supplier in North America who can provide such a ring or does it have to be ordered from Germany?

Attachments

... it looks ok. I would choose steel balls.

I have no idea where to buy in North America. It is a part from the furniture industry (maybe that helps).

Heinrich

I have no idea where to buy in North America. It is a part from the furniture industry (maybe that helps).

Heinrich

Since the Phidgets motor is no longer availible, what is the next best choice?

When looking at gear motors with encoders, I have the option of "Absolute" or "Incremental" encoding. Which is the correct type of encoding for the drive motor?

When looking at gear motors with encoders, I have the option of "Absolute" or "Incremental" encoding. Which is the correct type of encoding for the drive motor?

Interesting that this topic popped back up, since I might actually have an interest/use in doing something like this. It seems like it could be 'fairly straightforward' to adapt cheap 3d printer / cnc control boards and stepper motors to do something like this. The code to send gcode over usb should be possible to separate out from something like UGS.

I guess you have to evaluate the time needed to set something like this up vs the time to make the manual measurements the X times you'll actually need to do it.

I guess you have to evaluate the time needed to set something like this up vs the time to make the manual measurements the X times you'll actually need to do it.

..... this Motor should work: Pololu - 150:1 Metal Gearmotor 37Dx73L mm 12V with 64 CPR Encoder (Helical Pinion)

…. and here the pinion: Stirnzahnrader aus Stahl, Modul 1,5 | MADLER Webshop

Regards

Heinrich

…. and here the pinion: Stirnzahnrader aus Stahl, Modul 1,5 | MADLER Webshop

Regards

Heinrich

Hello Heinrich,

I have not been able to find that ref 21801100 from Madler in France on the web

Any idea ?

Best regards

Jean Claude.

I have not been able to find that ref 21801100 from Madler in France on the web

Any idea ?

Best regards

Jean Claude.

..... this Motor should work: Pololu - 150:1 Metal Gearmotor 37Dx73L mm 12V with 64 CPR Encoder (Helical Pinion)

…. and here the pinion: Stirnzahnrader aus Stahl, Modul 1,5 | MADLER Webshop

Regards

Heinrich

For the motor, does the 67 RPM of the one you suggested vs. the original Phidgets 28 RPM motor matter? Will the platter spin too fast or does the controller control the speed?

Thank you,

David.

I have used the slewing ring from the furniture hardware manufacturer Häfele.

Part. no. 646.27.947

Works well with the Mädler pinion and a Pololu motor.

I got the 131:1 version. Part. no. 2827

--

Bjørn

Part. no. 646.27.947

Works well with the Mädler pinion and a Pololu motor.

I got the 131:1 version. Part. no. 2827

--

Bjørn

I am having great difficulty finding the slewing ring and gear.

Would this ring work?

Gedotec Schwerlast-Drehbeschlag 360deg Drehscheibe drehbar O 320 mm | Drehteller Stahl silber | Druckkugellager Tragkraft 300 kg | Dreh-Ring zum Schrauben fur Mobel - TV uvm. | 1 Stuck - Drehkranz Kuche: Amazon.de: Baumarkt

At least these guys will ship to Canada.

The Häfele in not availible in North America.

Any thoughts on a gear?

Would this ring work?

Gedotec Schwerlast-Drehbeschlag 360deg Drehscheibe drehbar O 320 mm | Drehteller Stahl silber | Druckkugellager Tragkraft 300 kg | Dreh-Ring zum Schrauben fur Mobel - TV uvm. | 1 Stuck - Drehkranz Kuche: Amazon.de: Baumarkt

At least these guys will ship to Canada.

The Häfele in not availible in North America.

Any thoughts on a gear?

- Home

- Loudspeakers

- Multi-Way

- Polar measurements with automatic turntable

![RAR20[1].jpg](/community/data/attachments/518/518713-2f7cd8c6d9d50d264cc0304caf857fa3.jpg?hash=L3zYxtnVDS)