The enclosure design and the type of use it sees factors into the material being used. Baltic birch has long been the pro audio standard for enclosures because it is dense, durable, and at least somewhat water resistant... compared to MDF for example which simply cannot get wet at all.

The cabinet design matters too because those with multiple internal panels such a folded horn are naturally more rigid than a big empty reflex cab. Subs also subject the cab to higher acoustic pressures and more severe vibration so the cabinet needs to be more massive.

Assembly techniques can help with all this and enable the use of thiner materials in some cases, I built 12+1 trapezoid reflex cabs from 1/2" ply with rabbet joints on the external panels and the baffle and an internal brace fit into dado slots on all 4 sides. This cab would stand completely assembled with no glue or fasteners, and it only required glue, some brad nails and a few clamps to complete.

I also built a Cubo sub test box from 3/4 ply with similar techniques... the internal panels fit into dado slots. When I was done testing it was extremely difficult to dismantle.. I was swinging a sledge hammer at it and not doing much damage, I think I ended up cutting it apart because there was no way the wood was going to be salvageable.

The cabinet design matters too because those with multiple internal panels such a folded horn are naturally more rigid than a big empty reflex cab. Subs also subject the cab to higher acoustic pressures and more severe vibration so the cabinet needs to be more massive.

Assembly techniques can help with all this and enable the use of thiner materials in some cases, I built 12+1 trapezoid reflex cabs from 1/2" ply with rabbet joints on the external panels and the baffle and an internal brace fit into dado slots on all 4 sides. This cab would stand completely assembled with no glue or fasteners, and it only required glue, some brad nails and a few clamps to complete.

I also built a Cubo sub test box from 3/4 ply with similar techniques... the internal panels fit into dado slots. When I was done testing it was extremely difficult to dismantle.. I was swinging a sledge hammer at it and not doing much damage, I think I ended up cutting it apart because there was no way the wood was going to be salvageable.

i said about 6mm.... .35mm is less than half of a millimeter

so basically is nothing! 😋

That's what SHE said!

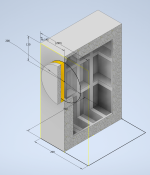

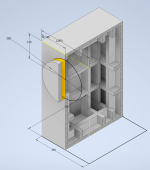

No, side panels have 2 vertical braces so the depth of the panel is divided into 3.Wow, is it brittle ?

I can see what you mean if a large enough panel was bent but still would need a lot of force to break it..

Do you have pics to share of the bracing layout? I'd like to learn how to approach the challenge of building with thinner plywoodI used 1/4bb for a 90L box and will use 1/4 again. The extensive bracing doesn't add a lot of weight because of the holes.

This is the expensive version of bracing, if wood cost don't matter. Looks impressing, but is not the only and best way to do it.

Uprigth stripes of wood, about 3 times the panel strength high, give very good results and can be made from anything left over. You reduce the resonating panel area, lifting up the resonce frequency. I attach some pictures to explain the principle, as it is inside, beautiful doesn't matter.

The ultimate seems to reduce the free resonating panel surface to about 4"x4" or 10x10cm.

Uprigth stripes of wood, about 3 times the panel strength high, give very good results and can be made from anything left over. You reduce the resonating panel area, lifting up the resonce frequency. I attach some pictures to explain the principle, as it is inside, beautiful doesn't matter.

The ultimate seems to reduce the free resonating panel surface to about 4"x4" or 10x10cm.

Attachments

- Home

- Loudspeakers

- Subwoofers

- Plywood thickness for 18" subwoofer box