Hello to all,

I have built myself one of these machines from an old BSR turntable that does 78RPM, which is nice for faster cleaning.

Everything works okay, except that the nylon thread is not pulled in the tube by the vaccuum pump when I advance it by hand. I used 0.4mm nylon thread; the Monks use 30 gauge thread, which is closer to 0.25mm. Also sometimes i can see that a "haze" of water is left in the grooves. This dries in a minute, but i feel the succion could be better. Hoses are 1/4" vinyl.

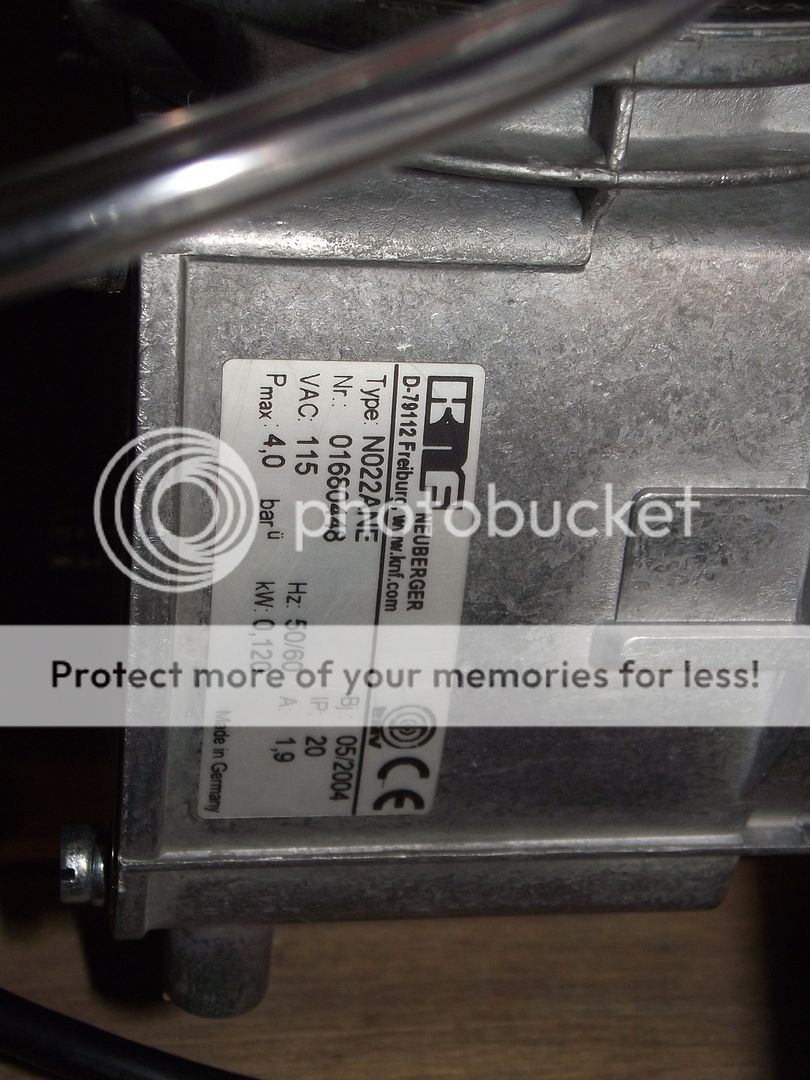

I was lucky enough to find the exact KNF pump model that is used in the Keith Monks (got it new for less than 100CAD ); so I'm sure the succion pressure is right. Could it be that the greater space between the nozzle and the disc, created by thicker thread, reduces the succion? And the thread having a greater weight aggravates the problem further causing it not to be pulled in? That's all I can think of, as everything else seems ok.

); so I'm sure the succion pressure is right. Could it be that the greater space between the nozzle and the disc, created by thicker thread, reduces the succion? And the thread having a greater weight aggravates the problem further causing it not to be pulled in? That's all I can think of, as everything else seems ok.

Below, some pictures to help you figure it out. A couple got stretched, don't know why...

Thanks in advance!

Joris

I have built myself one of these machines from an old BSR turntable that does 78RPM, which is nice for faster cleaning.

Everything works okay, except that the nylon thread is not pulled in the tube by the vaccuum pump when I advance it by hand. I used 0.4mm nylon thread; the Monks use 30 gauge thread, which is closer to 0.25mm. Also sometimes i can see that a "haze" of water is left in the grooves. This dries in a minute, but i feel the succion could be better. Hoses are 1/4" vinyl.

I was lucky enough to find the exact KNF pump model that is used in the Keith Monks (got it new for less than 100CAD

Below, some pictures to help you figure it out. A couple got stretched, don't know why...

Thanks in advance!

Joris

Ha! Talk about coincidence; I just spent most of the day researching vacuum pumps,thread and nozzles for the same project.

As you said,and from everything I've read,the thread diameter seems to be a bit critical.

The tip of your nozzle appears flat where the others I've seen appear more ''rounded'' which may be affecting flow.

What is the orifice diameter? Too small would reduce flow and maybe pinch the thread;too big and you loose suction.

Nice score on the pump,it looks brand new. Are there any more available?

Good luck!

As you said,and from everything I've read,the thread diameter seems to be a bit critical.

The tip of your nozzle appears flat where the others I've seen appear more ''rounded'' which may be affecting flow.

What is the orifice diameter? Too small would reduce flow and maybe pinch the thread;too big and you loose suction.

Nice score on the pump,it looks brand new. Are there any more available?

Good luck!

The only thingh I know is the nozzle bore diameter is 1.4 mm. The thread might be called size D for fishing rods. The Monks pump is over kill and cheaper can be better. You need a flow of > 10 Litres per minute and better than 250 mB. The cheaper KNF N828 is a better pump, it needs good anti vibation mounts or remote use.

If you find a good cord please post. The woven ones are best. Looks fantastic the adaption.

If you find a good cord please post. The woven ones are best. Looks fantastic the adaption.

Pass DIY Addict

Joined 2000

Paid Member

So, where do you find nylon/teflon nozzles to use for the vacuum pump for a project like this?

I have been looking all over and all I can find are steel nozzles that are intended for extruding melted nylon. Here is one example: Standard Nylon Replaceable Nozzle Tip

Any sources would be greatly appreciated!

I have been looking all over and all I can find are steel nozzles that are intended for extruding melted nylon. Here is one example: Standard Nylon Replaceable Nozzle Tip

Any sources would be greatly appreciated!

I don't see why they wouldn't work, great idea. The nozzel must not touch the record regardless of what it is made from. One kiss is the kiss of death. The tiny rope ensures it.

Anybody got an idea for a low cost platter drive that is quiet? I have tried a stepper motor which didn't like the work load. I wish I could buy a direct drive motor like Newmark. One that has 78 would be even better. It must be high torque. The microwave oven motors are too slow. The Chinese DC motor types lasted about 1 week and sound like cheap toys. I would build a motor if I have to. I was told on another thread I was a complete idiot when trying to discuss them ( it was worse and the moderator didn't pick it up, not my problem as I felt sorry for someone misunderstanding like that ). What this person didn't understand is I wanted to build a crude one. Someone uses a Garrard 201 circa 1937 as a potters wheel. Alas the Garrard is far from simple. It is direct drive without electronics. I know the maths of this. It is the details I lack. The 201 is close to my question. I have a 201 so know enough.

Anybody got an idea for a low cost platter drive that is quiet? I have tried a stepper motor which didn't like the work load. I wish I could buy a direct drive motor like Newmark. One that has 78 would be even better. It must be high torque. The microwave oven motors are too slow. The Chinese DC motor types lasted about 1 week and sound like cheap toys. I would build a motor if I have to. I was told on another thread I was a complete idiot when trying to discuss them ( it was worse and the moderator didn't pick it up, not my problem as I felt sorry for someone misunderstanding like that ). What this person didn't understand is I wanted to build a crude one. Someone uses a Garrard 201 circa 1937 as a potters wheel. Alas the Garrard is far from simple. It is direct drive without electronics. I know the maths of this. It is the details I lack. The 201 is close to my question. I have a 201 so know enough.

Pass DIY Addict

Joined 2000

Paid Member

There is none as far as I know. The round profile looks very promising.The venturi effect is assited by the cord. The shape of the liquid can be seen as an egg timer shape. The words I used in the past were mini tornado or vortex. The cord forces a screw like twist. You will find exact size is the big deal. This is why a Monks/Wilson machine cleans better than VPI etc. It is the vortex. If the pump can get down to 50 mBar absolute with about 28 litre/minute flow it is possible in a cool room to get ice. That's when the pump is too good. The cord will give you problems. Alas I don't have up to date imformation on that.

Pass DIY Addict

Joined 2000

Paid Member

I've been starting to build a set of notes and suppliers for this. It sounds like the specifics of thread construction is one of the keys.

Here is one supplier: Bonded Nylon Fiber, Nylon Thread, Upholstery Thread - Superior Threads

They offer a 2-ply Z-twist #46 (0.25mm diam) bonded nylon thread.

Here is another, but for #33 thread (0.20mm diam), though specific geometry is unspecified: size 33 white bonded nylon

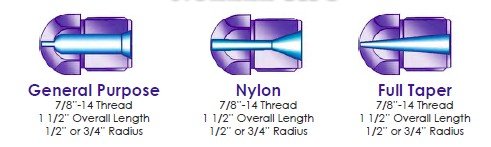

I found what looks like a good nozzle here -on page 4 of the PDF: http://plasti-co.com/links/TNS.pdf

It is a Leeco NTB-02GP-S nozzle and has a 3/4" radius with 1/16 orifice

The last part is which pump. All of these seem capable and it seems like the magic is balancing adequate CFM and pressure with the orifice size in the nozzle.

I like this one (medical grade, variable flow from 0-40 ltr/min): Madavac 172BS II Aspirator 121768 | eBay

Then there are smaller ones like: Gast MOA V111 KH Compressor Vacuum Pump 12 2 Amps 12V Runs Quiet with Cable 1 | eBay

Or this: Gast USA 24V Brushless Rotary Vane Air Pump Compressor 24 Volt DC Special | eBay

Need to look a little more deeply into specs. Not looking so suck a hole in the album, just remove the dirt...

Here is one supplier: Bonded Nylon Fiber, Nylon Thread, Upholstery Thread - Superior Threads

They offer a 2-ply Z-twist #46 (0.25mm diam) bonded nylon thread.

Here is another, but for #33 thread (0.20mm diam), though specific geometry is unspecified: size 33 white bonded nylon

I found what looks like a good nozzle here -on page 4 of the PDF: http://plasti-co.com/links/TNS.pdf

It is a Leeco NTB-02GP-S nozzle and has a 3/4" radius with 1/16 orifice

The last part is which pump. All of these seem capable and it seems like the magic is balancing adequate CFM and pressure with the orifice size in the nozzle.

I like this one (medical grade, variable flow from 0-40 ltr/min): Madavac 172BS II Aspirator 121768 | eBay

Then there are smaller ones like: Gast MOA V111 KH Compressor Vacuum Pump 12 2 Amps 12V Runs Quiet with Cable 1 | eBay

Or this: Gast USA 24V Brushless Rotary Vane Air Pump Compressor 24 Volt DC Special | eBay

Need to look a little more deeply into specs. Not looking so suck a hole in the album, just remove the dirt...

The Madavac is 22" or 559 mm Hg , That is 745 mBar or 255 mBar absolute ( 1 - 0.745 ) . That is exactly the right figure as a good minimum ( read ideal if good collection jar seal ). The Monks if I am right is a KNF N022 ANE at 15 litres and 100 mBar, I know it from the make and the look. The Madavac looks almost a clone and is at a very good price. 40 litre flow is what I like. 15 litre is enough.

All I can say about the thread is about 1/3 the size of the nozzle hole from memory or smaller. Not as small as sewing cotton. 1/16th is excellent. Looking at what you sent as drawings of nozzles it would be worth playing with them all. When the thread is too small the record gets marked, when too large you get wet patches. Sorry to say it is the one thing I never wrote down. It was made by " The Talbot " in the UK. They went bust.

All I can say about the thread is about 1/3 the size of the nozzle hole from memory or smaller. Not as small as sewing cotton. 1/16th is excellent. Looking at what you sent as drawings of nozzles it would be worth playing with them all. When the thread is too small the record gets marked, when too large you get wet patches. Sorry to say it is the one thing I never wrote down. It was made by " The Talbot " in the UK. They went bust.

So, where do you find nylon/teflon nozzles to use for the vacuum pump for a project like this?

I have been looking all over and all I can find are steel nozzles that are intended for extruding melted nylon. Here is one example: Standard Nylon Replaceable Nozzle Tip

Any sources would be greatly appreciated!

Hi Eric,

When I was building my RCM,I fashioned the tip from 1/4'' teflon rod,which was sourced from McMaster-Carr. I believe the original on the Loricraft machines was nylon. The 1 foot length cost about 5 bucks.

As for thread,this was the biggest pain in the a** of the entire project.

Luckily,my girlfriend went to Norwalk,Connecticut, to visit her brother with the idea of visiting local fishing-tackle shops during her stay. This thread is (was?) commonly used for building fishing rods. I wish I could have seen the salesmans face when she told him she wanted it for a record cleaning machine!

She brought me back 4 spools; 2 Gudebrod (the brand supplied by Loricraft after Talbot closed down,but now they're also gone),1 ProWrap and 1 FishHawk. All in ''D'' size,and with the same characteristics as the original spec. The diameter between ''D'' and ''E'' is so close as to be negligible,so get what's easier.

All were under $4 a spool. By comparison,the Canadian Loricraft dealer wanted $10 a spool,plus $15 shipping!

Pass DIY Addict

Joined 2000

Paid Member

audio king: Thanks for the heads up on the Gudebrod! I just found another DIY effort on a Dutch web site that also featured the Gudebrod thread. I just ordered some in "E" size from ebay for about $1 each. I think I'll pick up 2-3 different nozzles to play with and a good size pump so I have some flexibility to experiment with.

For the nozzle I used desoldering pump solder replacement tips.So, where do you find nylon/teflon nozzles to use for the vacuum pump for a project like this?

I have been looking all over and all I can find are steel nozzles that are intended for extruding melted nylon. Here is one example: Standard Nylon Replaceable Nozzle Tip

Any sources would be greatly appreciated!

Here's the exact ones I bought, 5.65$ for a pack of 5

Good luck with your project!

Joris

audio king: Thanks for the heads up on the Gudebrod! I just found another DIY effort on a Dutch web site that also featured the Gudebrod thread. I just ordered some in "E" size from ebay for about $1 each. I think I'll pick up 2-3 different nozzles to play with and a good size pump so I have some flexibility to experiment with.

Gudebrod, that's the one I know. The problem you will find is not damaging the records. Inspect each one carefully when you start as sometimes the damage was already there. You will need many that have no value to test with. You could try a 78 just to get the basics right.

Pass DIY Addict

Joined 2000

Paid Member

Thanks for the ebay links, guys!

The solder sucker nozzles are certainly cost friendly! I think the key for a DIY effort is likely to be the relationships between CFM, orifice diameter, and thread diameter.

One of the things I like about the 3/4" radius steel nozzles is the wide and more gentle curve. While it may be illusory, it makes me think the thread will have a better chance at keeping the nozzle off the LP as it spins. I'll have to think carefully about the necessary support hardware and counter weight so it doesn't get too heavy on the end.

Nigel - I saw that same pump, but the guy wants $70 for shipping, which makes the total package not price competitive with others. I'm thinking I'll stick with medical grade pumps. Somehow this makes me think they'll be a bit more quiet than others and perhaps a bit more durable. As with all other sectors of manufacturing, there seems to be a great many brands that feature identical construction, so brand to brand differences are negligible within the build family.

The solder sucker nozzles are certainly cost friendly! I think the key for a DIY effort is likely to be the relationships between CFM, orifice diameter, and thread diameter.

One of the things I like about the 3/4" radius steel nozzles is the wide and more gentle curve. While it may be illusory, it makes me think the thread will have a better chance at keeping the nozzle off the LP as it spins. I'll have to think carefully about the necessary support hardware and counter weight so it doesn't get too heavy on the end.

Nigel - I saw that same pump, but the guy wants $70 for shipping, which makes the total package not price competitive with others. I'm thinking I'll stick with medical grade pumps. Somehow this makes me think they'll be a bit more quiet than others and perhaps a bit more durable. As with all other sectors of manufacturing, there seems to be a great many brands that feature identical construction, so brand to brand differences are negligible within the build family.

I can't wait for it to come together. I suspect the 1/16 nozzel is a winner. All British engineers speak in mixed inch and metric, the ones I know that is. We none of us have trouble and find it better. We often buy in inches and machine down to mm. 2 x 1 machines to 50 x 25. Inch material is cheaper as a rule. For example a centre spindle is 9/32" set in 1888 I think. That is 7.14375mm. Linn stated the shinkage of vinyl is 3% max. You will find 7 mm is OK for a cleaning machine.

If making a turntable you might use 9/32 and buy a 9/32 reamer. A very cheap way to have a perfect result. 7.1 mm I suspect would be best. These are off the shelf reamers. Why Beliner didn't use 1/4" I will never know. Maybe it looked wrong? I bought a motor this week. It is 6.3mm and German. It is neither inch nor metric. A very big company so a choice no doubt? Maybe it is 1/4 inch bearings with a big clearence on the shaft? Still very strange for a Germany company to use imperial if they did.

If making a turntable you might use 9/32 and buy a 9/32 reamer. A very cheap way to have a perfect result. 7.1 mm I suspect would be best. These are off the shelf reamers. Why Beliner didn't use 1/4" I will never know. Maybe it looked wrong? I bought a motor this week. It is 6.3mm and German. It is neither inch nor metric. A very big company so a choice no doubt? Maybe it is 1/4 inch bearings with a big clearence on the shaft? Still very strange for a Germany company to use imperial if they did.

As Nigel said, the id of the Monk and Loricraft nozzles is 1.4mm,which is 0.0551''.

Close enough to 1/16 (0.0625) for government work.

I initially considered using solder-sucker nozzles,but I felt that the id was WAY too big,and the end was flat-sided as well,not rounded as the originals are.

I chose Teflon (really really slippery) just for safety's sake in case of an oops

Oh,and Nigel,where in the hell does one find an 8BA countersunk screw in Canada!?!? Damned SME...and Norton...and Triumph etc etc.....

Close enough to 1/16 (0.0625) for government work.

I initially considered using solder-sucker nozzles,but I felt that the id was WAY too big,and the end was flat-sided as well,not rounded as the originals are.

I chose Teflon (really really slippery) just for safety's sake in case of an oops

Oh,and Nigel,where in the hell does one find an 8BA countersunk screw in Canada!?!? Damned SME...and Norton...and Triumph etc etc.....

Last edited:

We can't get them either. I think 2 mm will work if not too deep. Railway modelers have them. Don't get me onto motorcycles. I owned the last ever real. Triumph and didn't realise Tiger 750 Export LFC 824N ( Might buy a Kawasaki M800/650 ). My engineer tells me BA is a British metric thread ( I seem to remember one is isometric and one radian ). That's about 3 degrees different. If memory is right M2 is about 0.3 mm smaller and slightly tighter ( < 10 % ). Where needs must they often work. Thorens used M2.

Machine Screws

http://www.ba-bolts.co.uk/steelcsk.html

What drive motor has been settled on for the plater?

Machine Screws

http://www.ba-bolts.co.uk/steelcsk.html

What drive motor has been settled on for the plater?

Last edited:

Pass DIY Addict

Joined 2000

Paid Member

I chose Teflon (really really slippery) just for safety's sake in case of an oops

Do you have a link/image/etc for the tip you chose? I'd like a teflon one, but will settle for the rounded steel if I cant find something I like.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Please help with DIY "Keith Monks" record cleaning machine problem