Greetings Friends.

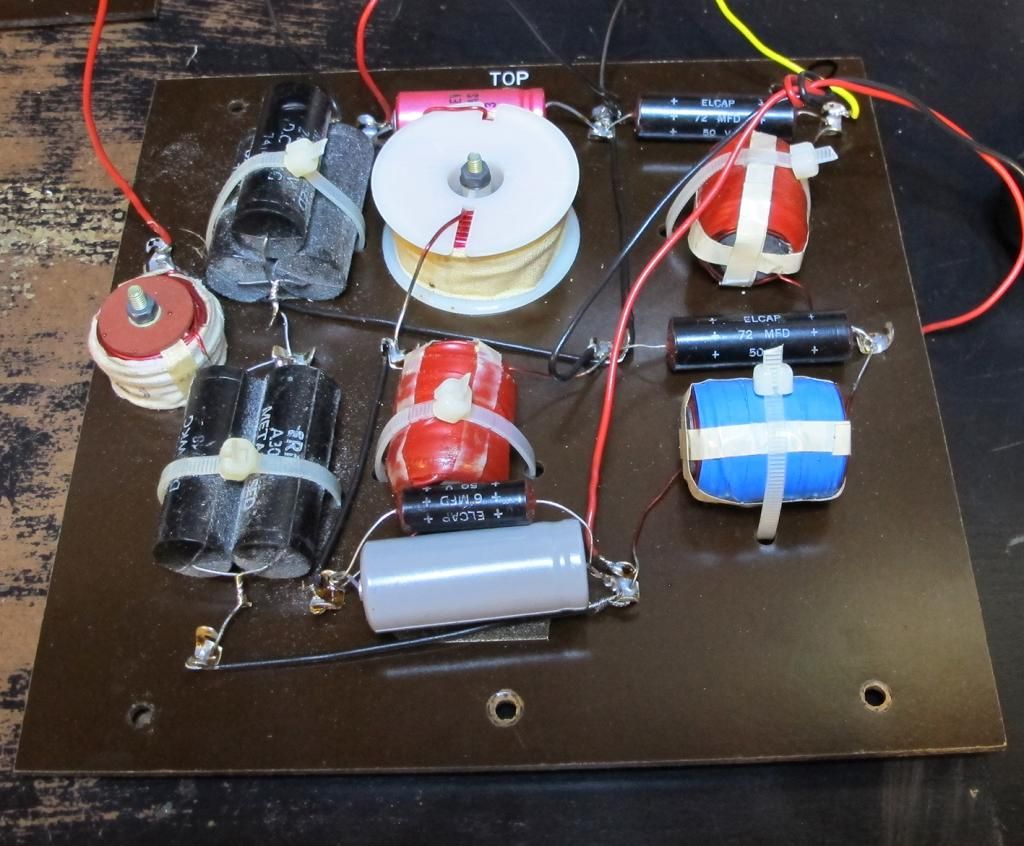

I'm restoring a pair oof Celestion Ditton 44, and have extracted these capacitors from the Crossover:

Maybe you guys could help me identify the polarity and dielectric please.

1 - Seems a bipolar capacitor, unknown dielectric. markings are "ELCAP 72uf/50v N.P." I think "NP" may stand for "non polarised" but would love a confirmation on this subject.

2 - This one gots me confused. It seems another bipolar type, but the band in one side keeps me concerned. Markings are "ERIE A304 METALLISED 2.0uf/150v DC WKG 74/46"

3 - these ones seems traditional electrolithic capacitors, but all electrolithics I have seen had a clear "minus" mark in the cathose. these ones have no marks, apart from the band in one side. Markings are "24uF 25VC CREV WE 99RAS 8 75 8" in one and in the other "CCL 6uF/50v REV WG 75CRAS MAR73"

Could someone help me identify them please?

btw you can find the restoration thread here: http://www.diyaudio.com/forums/mult...g-modernising-pair-celestion-ditton-44-a.html

Many thanks guys

I'm restoring a pair oof Celestion Ditton 44, and have extracted these capacitors from the Crossover:

Maybe you guys could help me identify the polarity and dielectric please.

1 - Seems a bipolar capacitor, unknown dielectric. markings are "ELCAP 72uf/50v N.P." I think "NP" may stand for "non polarised" but would love a confirmation on this subject.

2 - This one gots me confused. It seems another bipolar type, but the band in one side keeps me concerned. Markings are "ERIE A304 METALLISED 2.0uf/150v DC WKG 74/46"

3 - these ones seems traditional electrolithic capacitors, but all electrolithics I have seen had a clear "minus" mark in the cathose. these ones have no marks, apart from the band in one side. Markings are "24uF 25VC CREV WE 99RAS 8 75 8" in one and in the other "CCL 6uF/50v REV WG 75CRAS MAR73"

Could someone help me identify them please?

btw you can find the restoration thread here: http://www.diyaudio.com/forums/mult...g-modernising-pair-celestion-ditton-44-a.html

Many thanks guys

Last edited:

I think you will find;

1 Non Polarized is correct.

2 Non Polarized again.

The end mark is part of the manufacturing process. They have to stick the end cap on and one end has to be it.

3 Non Polarized Electrolytic. The 24u is dated 8th week 1975 the other you know.

Probably part of a passive crossover system.

1 Non Polarized is correct.

2 Non Polarized again.

The end mark is part of the manufacturing process. They have to stick the end cap on and one end has to be it.

3 Non Polarized Electrolytic. The 24u is dated 8th week 1975 the other you know.

Probably part of a passive crossover system.

many thanks for the fast reply. Do you know what "Metallised" in #2 and "REV" "RAS" "WE" and "WG" in #3s stands for?

I understand that 74 46 in #2 stands for 46th week of 1974?

Btw they are part of a Celestion Ditton 44 Crossover 😉

I understand that 74 46 in #2 stands for 46th week of 1974?

Btw they are part of a Celestion Ditton 44 Crossover 😉

Last edited:

I would say:

number 1 and 3 are bipolar electrolytic caps............

n. 2 are metallised film caps (e. g. MKT,MKP).......

number 1 and 3 are bipolar electrolytic caps............

n. 2 are metallised film caps (e. g. MKT,MKP).......

Metalised is metalised polypropylene.

This special construction enables capacitor to withstand higher switching surges. In case of Oil filled capacitors assembly is done in CRCA container and impregnated with NPCB oil. For dry type capacitors assembly is done in aluminium can containers and are impregnated with polyurethane resin / wax. These moudles have pressure interrupter arrangement for safety against bursting Both designs are vailable in normal duty and heavy duty applications.

WE and WG is part of the manufacturers factory code.

Hope that helps.

This special construction enables capacitor to withstand higher switching surges. In case of Oil filled capacitors assembly is done in CRCA container and impregnated with NPCB oil. For dry type capacitors assembly is done in aluminium can containers and are impregnated with polyurethane resin / wax. These moudles have pressure interrupter arrangement for safety against bursting Both designs are vailable in normal duty and heavy duty applications.

WE and WG is part of the manufacturers factory code.

Hope that helps.

Thanks mjf

So #1 and #3 are both non polar electrolithics?

Jonsnell you knowing of capacitors keeps me astonished 😱. Do you work in a capacitor factory by any chance? 😀

Anyway, what modern replacements would you advice for these? Any brand/type?

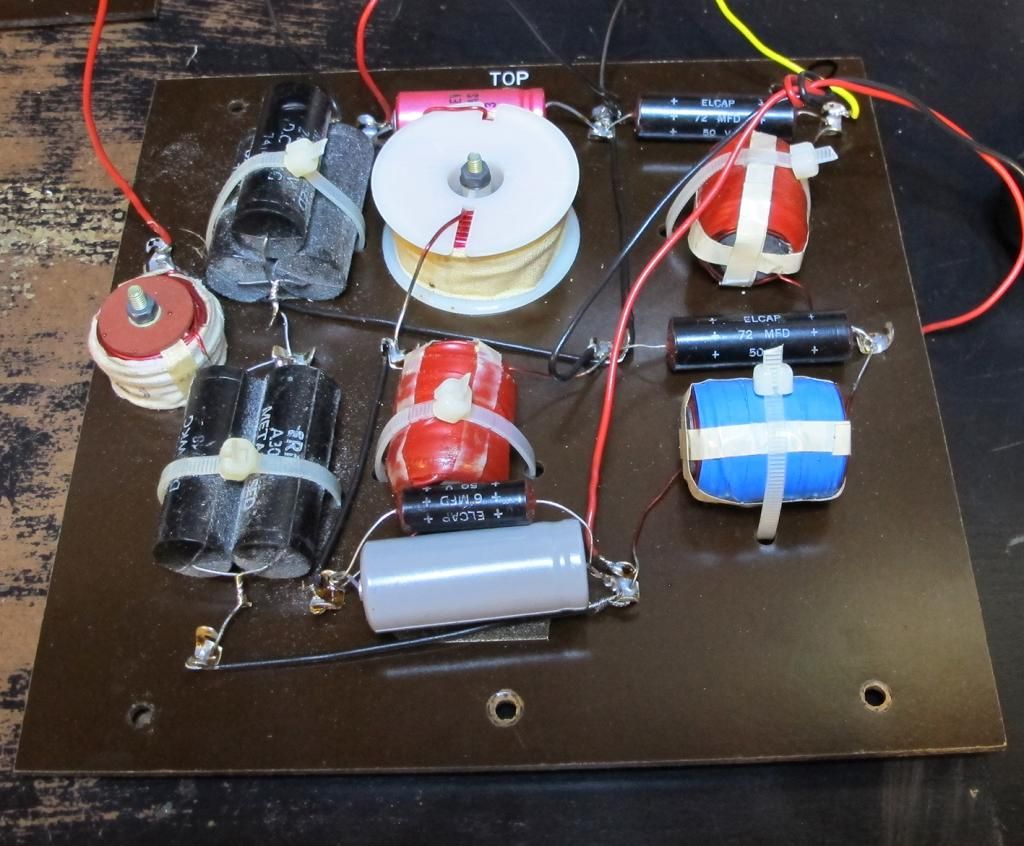

Oh allmost forgot, heres a pic of the original Crossover:

Why should they mount those capacitors in parallel? Are they just aiming for some ohm value or it does affect the sound?

We can see a #1 and #3 mounted in parallel, this indicates they are the same type (non polar electrolithics?) or would you mount a non polarised non electrolithic, and a non polarised electrolithic together without problem?

Many thanks for your replys guys.

So #1 and #3 are both non polar electrolithics?

Jonsnell you knowing of capacitors keeps me astonished 😱. Do you work in a capacitor factory by any chance? 😀

Anyway, what modern replacements would you advice for these? Any brand/type?

Oh allmost forgot, heres a pic of the original Crossover:

Why should they mount those capacitors in parallel? Are they just aiming for some ohm value or it does affect the sound?

We can see a #1 and #3 mounted in parallel, this indicates they are the same type (non polar electrolithics?) or would you mount a non polarised non electrolithic, and a non polarised electrolithic together without problem?

Many thanks for your replys guys.

Krorghar,

I can't believe you used some WBT posts in your Celestion Ditton 44 vintage restoration, "hehe!"

Maybe a picture of the original posts would be fun to look at (@your linked thread).

I can't believe you used some WBT posts in your Celestion Ditton 44 vintage restoration, "hehe!"

Maybe a picture of the original posts would be fun to look at (@your linked thread).

I go back many years and worked for companies like Plessey, BHC, Welwyn, Decca, Mullard and others in the QA and Design section. Got to see a lot of different designs and ideas that didn't work or were un successful. Hence date codes etc.

Mounting in parallel adds the capacity, to match the compression drivers specifications and could be more cost effective than sourcing very expensive special components.

Your pocket depth determines the type of capacitors you would like. Take your pick from a selection from Mouser, RS Components, Farnell etc.

Mounting in parallel adds the capacity, to match the compression drivers specifications and could be more cost effective than sourcing very expensive special components.

Your pocket depth determines the type of capacitors you would like. Take your pick from a selection from Mouser, RS Components, Farnell etc.

Krorghar,

I can't believe you used some WBT posts in your Celestion Ditton 44 vintage restoration, "hehe!"

Maybe a picture of the original posts would be fun to look at (@your linked thread).

Well is a restoration, and also a bit of modernization 😀. The original post are so small that no modern spade will fit in, and also dont have banana holes. Sometimes you have to decide if you will keep the original or would be better to go for a modern upgrade.

The posts is one of these cases where a modernization is needed 😱 here are the originals:

The diameter of the central pilon under the fastener is only 2mm, while modern spades are 6 and 8 mm. also as you can see, no banana holes 😉 so though I would have liked to conserve the originals, it is not an option if I want a decent connection.

Last edited:

I go back many years and worked for companies like Plessey, BHC, Welwyn, Decca, Mullard and others in the QA and Design section. Got to see a lot of different designs and ideas that didn't work or were un successful. Hence date codes etc.

Mounting in parallel adds the capacity, to match the compression drivers specifications and could be more cost effective than sourcing very expensive special components.

Your pocket depth determines the type of capacitors you would like. Take your pick from a selection from Mouser, RS Components, Farnell etc.

Thanks JonSnell. So would you advice some quality prolipropilene capacitors here? Should I replace all of them? even the non polar electrolithics?

The 72uF ones in polipropilene are really big (4cm diameter for 8cm lomg) and also very expensive. Any another option? Also it seems the 72uf value is hard to find, I have found 68uF ands 75uF but not 72. Should I get the exact value adding some capacitors in paralel or can I go with 68 or 75?

About the volts, polypropylenes are 250v. as the volts in the capacitors are 50 in most of them, will this be a problem?

Many thanks friend.

As far as polypropylenes go, the available brands and types are countless. If you do not want to spend an arm and a leg on them, try Solen MKP-FC, or Jantzen Cross-Caps they are better than average, and reasonably priced. For the 72 uF, you should try a decent bipolar electrolytic, say 68uF/100V, and bypass them with 3.9-4.7 uF MKP-s to get the target value. Anyway if you measure yor 72uF old bipolars, be prepared to get anything from 50uF-100uF..... their tolerance and aging might give any results like that.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Please help me identifying some capacitors