A remotely hidden 5 -10 gallon air tank would take care of the worry of air noise I would think.

The Cartridge Man Conductor air bearing tonearm (for one) came with a tank used both to deal with condensation issues at the bearing itself and in addition sized to average out any pressure variations from the pump, a fish tank air pump, available in models that are very quiet. A friend had one with pump installed in closet and air hose out to tank fairly close to the tonearm.

About the vanes, they could be anything from precisely located nubs of any useful size and shape all the way up to more traditional vanes, perhaps perforated (or grids) to minimize turbulence at the edges. With current understanding and modelling capabilities .. . . . . . If you can drop a rocket booster on a launchpad using little fins you can get a platter to spin the way you want.

As for speed control, what about a centrifugal governor in combination with the vanes?

Thinking a little more about drive and speed control, you could build the platter into a housing like a pneumatic motor. Then , self contained, you don't need to consider outside air movements affecting speed.

Internally then use shaped ducts with exits that allow the drive current to counteract the rotation - giving a resistance to work into for more stability.

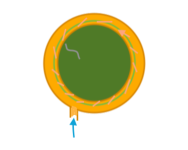

Sorry for the very basic drawing , osx preview is only graphic app I have. Orange is housing, solid green is platter , outer green circle is inner wall of air chamber with angled openings for air , grey is vane (possibly a tube) - of course only one of a best number, blue is air input, air return depends on build.

Just had another thought - could same air be used to float an air bearing ?

Internally then use shaped ducts with exits that allow the drive current to counteract the rotation - giving a resistance to work into for more stability.

Sorry for the very basic drawing , osx preview is only graphic app I have. Orange is housing, solid green is platter , outer green circle is inner wall of air chamber with angled openings for air , grey is vane (possibly a tube) - of course only one of a best number, blue is air input, air return depends on build.

Just had another thought - could same air be used to float an air bearing ?

Attachments

Last edited:

Platter circumference would be the best place to put resistance for air to move. Least energy required.

Yes, I think so too but was exploring the notion of using the same air for both forward push and also some resistance to work into, though now I think the physics might not work that way.

A mock-up would be easy to build with plywood . I don't have a shop to use but when I get out to a friend's place I can cut the parts for it . Two strips of 1/8" or 1/4" ply for the walls and anything at all for the base and top. A little paint to seal the air chamber well enough to play with it. Circular cutouts from speaker builds for a platter and away we go.

Of course their are other ways to get air drive .

A mock-up would be easy to build with plywood . I don't have a shop to use but when I get out to a friend's place I can cut the parts for it . Two strips of 1/8" or 1/4" ply for the walls and anything at all for the base and top. A little paint to seal the air chamber well enough to play with it. Circular cutouts from speaker builds for a platter and away we go.

Of course their are other ways to get air drive .

The amount of air required to turn a platter on a very low friction bearing would be minimal I think. Regulating that speed is where I think the big problem would be. A super small difference in air flow might result in a 35 or 31 rpm speed. It might need adjusting all the time due to temperature and humidity changes.

Thermal changes would be the initial concern - changing bearing but also jet parameters. That is before the expansion temperature cool down.

Poking away at this and doing a few sketches the light went on.

What makes air attractive is air's lossiness, - compressability that damps noise from the driving motor .

But any drive system has to deal with stylus' dynamic drag which will vary all the time, so it the drive needs to work into a much greater effective resistance that swamps those drag effects. To work into this resistance you could then go to compressed air or even fluids for drive but the more positive you get, the closer to a simple rubber band is the result.

What makes air attractive is air's lossiness, - compressability that damps noise from the driving motor .

But any drive system has to deal with stylus' dynamic drag which will vary all the time, so it the drive needs to work into a much greater effective resistance that swamps those drag effects. To work into this resistance you could then go to compressed air or even fluids for drive but the more positive you get, the closer to a simple rubber band is the result.

Last edited: