Hello all,

Seeking opinions on question about perf stator open area and hole sizes:

I'm considering replacing the stators in my ESL's to see how they would sound with 51% open stators versus my current .125 hole/40% open stators.

Maybe I should leave wonderful alone but, hey, I'm curious and experimenting is part of the ESL psychosis, right? (I was perfectly content until Mavric got me started with this shzzt again)

Panels are flat, 12" x 48" with 1/16" d/s spacing.

Today I searched and found a retail source for 48" width perf (McNichols). I decided 3/16 holes would be too large for my 1/16" d/s spacing but I got quotes for two other options:

18 gauge (.048) steel, 9/64 (.141) holes, 51% open:

48x120 sheet, 1-sheet min-buy yields 8 stators, cutting+shipping = $225

22 gauge (.030) steel, .117 holes, 51% open:

36x120 sheet, 1-sheet min-buy yields 4 stators, cutting+shipping = $165

I think the .117 holes would give better efficiency but the net cost is higher, since the shorter width would yield only (4) 12 x 48 pieces and much waste.

Question 1: Would the smaller .117 holes tend to close up when coated.

Question 2: Would the thinner (.030) flat stators ring (resonate)?

Question 3: Efficiency aside, is 51% open sonically better than 40% open?

Seeking opinions on question about perf stator open area and hole sizes:

I'm considering replacing the stators in my ESL's to see how they would sound with 51% open stators versus my current .125 hole/40% open stators.

Maybe I should leave wonderful alone but, hey, I'm curious and experimenting is part of the ESL psychosis, right? (I was perfectly content until Mavric got me started with this shzzt again)

Panels are flat, 12" x 48" with 1/16" d/s spacing.

Today I searched and found a retail source for 48" width perf (McNichols). I decided 3/16 holes would be too large for my 1/16" d/s spacing but I got quotes for two other options:

18 gauge (.048) steel, 9/64 (.141) holes, 51% open:

48x120 sheet, 1-sheet min-buy yields 8 stators, cutting+shipping = $225

22 gauge (.030) steel, .117 holes, 51% open:

36x120 sheet, 1-sheet min-buy yields 4 stators, cutting+shipping = $165

I think the .117 holes would give better efficiency but the net cost is higher, since the shorter width would yield only (4) 12 x 48 pieces and much waste.

Question 1: Would the smaller .117 holes tend to close up when coated.

Question 2: Would the thinner (.030) flat stators ring (resonate)?

Question 3: Efficiency aside, is 51% open sonically better than 40% open?

As soon as we get those ones i have cut and sprayed, is there anyway to test them? without the enclosure.

As soon as we get those ones i have cut and sprayed, is there anyway to test them? without the enclosure.

Yes, if you assemble them at my shop, you can easily test them here... don't worry they will sound wonderful.

so, well, umm, i guess i am on stand by, if you opt and go for larger holes, the three questions you posted have me wondering.

> if the the stator i am buildind is a little smaller, would larger holes help?

> resonance, same question

> and last, how much are they for the perf panels? I could go ahead and purchase, prep and spray them both.

what do you think? you just put a plan A and plan B infront of me. I cant understand how you can you something sound better than what you have. but as you mentioned, this is an experiment, i guess as i proposed a differnt coating, lets have fun with it, we are not getting any younger and our hearing isnt getting better, so i agree Charlie, get a price and i will go in half on the adventure. as long as the electronics work on the same plane as what we allready have going. now on the other hand, if you wish to let go of your currrent hybrids, I will bring a truck, and a cherry picker, those are pretty heavy. Later,

> if the the stator i am buildind is a little smaller, would larger holes help?

> resonance, same question

> and last, how much are they for the perf panels? I could go ahead and purchase, prep and spray them both.

what do you think? you just put a plan A and plan B infront of me. I cant understand how you can you something sound better than what you have. but as you mentioned, this is an experiment, i guess as i proposed a differnt coating, lets have fun with it, we are not getting any younger and our hearing isnt getting better, so i agree Charlie, get a price and i will go in half on the adventure. as long as the electronics work on the same plane as what we allready have going. now on the other hand, if you wish to let go of your currrent hybrids, I will bring a truck, and a cherry picker, those are pretty heavy. Later,

fwiw ER Audio reckon "thin grids simply sound better"Question 2: Would the thinner (.030) flat stators ring (resonate)?

Question 3: Efficiency aside, is 51% open sonically better than 40% open?

See their ideas on design philosophy half way down this page:

Acorn Electrostatic Loudspeaker Kit

I've tried a few patterns. Bigger hole stators certainly have more openness in sound. However, the efficiency is lower, and, in my case, cause deficiency in dynamic.

Wachara C.

Wachara C.

What got me thinking about all this is that Martin Logan now uses what they call "micro-perf" stators with much smaller holes; which should present a more uniform electric field to the diaphragm--- a better compromise for open area and efficiency. The downside is that as the holes get smaller the stator must get thinner so that the holes do not become cylinders. Martin-Logan's panels are curved;thus, much stiffer and more resistant to ringing than a flat stator of similar thickness. In my case, I must use a flat stator to use in my existing speaker frame.

hi charlie, I have been meaning to get back to you on the open area topic, as i have been busy solving the transformer issue .

the very first panel I built used some preforated alu. (sofit vent) from home depot with 3/32" on about 7/64" centers, little did i know that the open area was only no more than 25% and even less with the coating as the holes were consideribly smaller by the time i got enough paint on them to properly insulate them from arcing of the high bias voltage i was using. So,when i finaly got them to produce a decent level ,i noticed right away that they were kind of dull sounding far away,but up close and next to my ear they were fine. I still have some of this material and will probably build some headphones from it.

That is when i switched to window screen it had 9.5mil wire at 16 holes per inch according to mcnichols charts this is an 71.9% open area.I then had the same issues of coating thickness,but they sounded great any how.Looking at the chart i estimate an open area of around 40%. As now my holes are roughly half the size i started with.But it did sound very good.

I then tried double powder coating ,as a single coat was not thick enough to handle the bias voltage. It was a much better insulator than the enamel i used and it yielded a much thinner and evenly coated coating than the paint.Thus,giving me a much higher percentage open area than with the paint.Right away i noticed a bigger,brighter and a more open sound.With such clarity that i wished it could be loud enough to feel it in my chest.

All of the panels had exactly the same size deminsions and stator spacings.As a i was investegating ,open area vs hole size and minimum and maximum hole sizes as well.but do to personal issues and properly driving the esl's, as stated before,i never got any farther than this.I plan on resuming my research and I am doing so now.

Also my bigger panles are exactly 4 times the surface area in oder to investagate the +6db gain increase in efficiancy theory.Not to mention better bass also.

These are some of the things i had tried to discuss with roger. but he would not give me a definite answer of what worked the best as he was being proprietory about his designs. I guess I can't blame him for that as R&D is expencive and time consuming.he assured me that he did not mind helping a diy'er and enjoyed doing so as he wrote his book for us.explaining how to do it using commonly available materials. jer

the very first panel I built used some preforated alu. (sofit vent) from home depot with 3/32" on about 7/64" centers, little did i know that the open area was only no more than 25% and even less with the coating as the holes were consideribly smaller by the time i got enough paint on them to properly insulate them from arcing of the high bias voltage i was using. So,when i finaly got them to produce a decent level ,i noticed right away that they were kind of dull sounding far away,but up close and next to my ear they were fine. I still have some of this material and will probably build some headphones from it.

That is when i switched to window screen it had 9.5mil wire at 16 holes per inch according to mcnichols charts this is an 71.9% open area.I then had the same issues of coating thickness,but they sounded great any how.Looking at the chart i estimate an open area of around 40%. As now my holes are roughly half the size i started with.But it did sound very good.

I then tried double powder coating ,as a single coat was not thick enough to handle the bias voltage. It was a much better insulator than the enamel i used and it yielded a much thinner and evenly coated coating than the paint.Thus,giving me a much higher percentage open area than with the paint.Right away i noticed a bigger,brighter and a more open sound.With such clarity that i wished it could be loud enough to feel it in my chest.

All of the panels had exactly the same size deminsions and stator spacings.As a i was investegating ,open area vs hole size and minimum and maximum hole sizes as well.but do to personal issues and properly driving the esl's, as stated before,i never got any farther than this.I plan on resuming my research and I am doing so now.

Also my bigger panles are exactly 4 times the surface area in oder to investagate the +6db gain increase in efficiancy theory.Not to mention better bass also.

These are some of the things i had tried to discuss with roger. but he would not give me a definite answer of what worked the best as he was being proprietory about his designs. I guess I can't blame him for that as R&D is expencive and time consuming.he assured me that he did not mind helping a diy'er and enjoyed doing so as he wrote his book for us.explaining how to do it using commonly available materials. jer

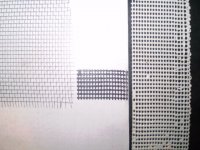

Attachments

Hey Charlie,

It's certainly tempting to assume more open stators must yield more "open" (transparent?) sound. I don't have any data/observations to support or refute that assertion but I remain suspicious that many builders start with very open stators and then add fibrous resistance, like felt, to damp resonances. Why not start with stators with less open area to begin with? It seems to me that that the stators are so close to the diaphragms that they just look like an acoustic resistance as far as the diaphragm is concerned. This is definitely conjecture until I finish my 24 gauge magnet wire stator (~40% open area) panels, but that's the reasoning I'm working from.

Few

It's certainly tempting to assume more open stators must yield more "open" (transparent?) sound. I don't have any data/observations to support or refute that assertion but I remain suspicious that many builders start with very open stators and then add fibrous resistance, like felt, to damp resonances. Why not start with stators with less open area to begin with? It seems to me that that the stators are so close to the diaphragms that they just look like an acoustic resistance as far as the diaphragm is concerned. This is definitely conjecture until I finish my 24 gauge magnet wire stator (~40% open area) panels, but that's the reasoning I'm working from.

Few

I agree with you,Few,on that one. My question is this: At which piont does the hole size become too large and cause a defficiancy in loudness and also a lesser force apon the diagphram ,thus reducing the dampening effect of the applied electrostatic forces on the stators caused from the bias supply?

My next design will use a wire mesh of 8 to 12 holes per inch with the same wire size (or very slightly larger depending on whats available) in order to greatly increase the open area while maintaining a highly concentrated and uniform electrostatic field per square inch.

Also by using the thinnest wire I can get I can apply a thicker coating of insulation dielectric ,thus allowing the use of a higher bias voltage with a reduced risk of arcing. Therefore increasing the dampening factor and sensitivity tremendously. jer

My next design will use a wire mesh of 8 to 12 holes per inch with the same wire size (or very slightly larger depending on whats available) in order to greatly increase the open area while maintaining a highly concentrated and uniform electrostatic field per square inch.

Also by using the thinnest wire I can get I can apply a thicker coating of insulation dielectric ,thus allowing the use of a higher bias voltage with a reduced risk of arcing. Therefore increasing the dampening factor and sensitivity tremendously. jer

Hey Charlie,

It's certainly tempting to assume more open stators must yield more "open" (transparent?) sound. I don't have any data/observations to support or refute that assertion but I remain suspicious that many builders start with very open stators and then add fibrous resistance, like felt, to damp resonances. Why not start with stators with less open area to begin with? It seems to me that that the stators are so close to the diaphragms that they just look like an acoustic resistance as far as the diaphragm is concerned. This is definitely conjecture until I finish my 24 gauge magnet wire stator (~40% open area) panels, but that's the reasoning I'm working from.

Few

You might have a point there, Few, as my 40% open stators do sound superb. Even so, I wonder what more open configurations would sound like because I really haven't had an opportunity to seriously critique any stats except my own. One point I would make about your 40% wire stators is this: I don't know that you can equate the sound of 40% open wire stators to that of 40% open perf stators, since the wires present convex surfaces to the sound as compared to the flat surfaces of a perf metal stator. I may be all wrong about this but I would bet that [open areas being the same] a wire stator would sound more open and clean because there would be almost no direct reflections from the stator back to the diaphragm. (yes, I have secret desire to build a wire-stator speaker 🙂

I agree with you,Few,on that one. My question is this: At which piont does the hole size become too large and cause a defficiancy in loudness and also a lesser force apon the diagphram ,thus reducing the dampening effect of the applied electrostatic forces on the stators caused from the bias supply?

My next design will use a wire mesh of 8 to 12 holes per inch with the same wire size (or very slightly larger depending on whats available) in order to greatly increase the open area while maintaining a highly concentrated and uniform electrostatic field per square inch.

Also by using the thinnest wire I can get I can apply a thicker coating of insulation dielectric ,thus allowing the use of a higher bias voltage with a reduced risk of arcing. Therefore increasing the dampening factor and sensitivity tremendously. jer

Hey, I'm with you on the larger hole size being less efficient. I figured to sort of have my cake and eat it too by reducing the hole size and upping the open area from 40% to 51%. That is; I'm thinking that decreasing the hole size would somewhat offset the loss from increasing the open area, since the smaller holes would present a tighter/more uniform electric field.

yes,charlie,my piont exactly.i was looking over the mcnichols catalog today and found a few 63% panels that might do very well.i wouldn't worry to much about them ringing as the coating is going to dampen it quite abit.even though i have read about it might being an issue (might?). i have never really read any serious complaints or graphs that showed it degrading the sound at all.you'd have to do some searchs on some very very early threads (2003-06)to find those discussions. jer

I found that sound improved when going from 35% open area (d 5mm s 8mm) to 51% (d 3mm s 4 mm).

But I also found out that going from 6µm film to 3µm did abt. the same! 😉

/R

But I also found out that going from 6µm film to 3µm did abt. the same! 😉

/R

yes.the high end does improve with a thinner and ligter material as i have tried many types and thicknesses .sadly though only 12 is availible here in the states.however i can get some 1.5 um, but only in 3" width.jer

I think you have to think of the stator hole size as it compares to the stator-diaphragm distance rather than in absolute terms. I'd start to get concerned when the hole size gets significantly bigger than the stator-diaphragm distance.

Capacitors with perforated plates have roughly the same capacitance as those with solid plates as long as the holes are small compared to the plate separation (and as long as we're limiting the discussion to signals whose wavelengths are large compared to all the other dimensions under consideration). Since ESL panels are basically capacitors, capacitors' insensitivity to the details of small perforations in their plates seems pertinent, but I don't know how to quantify the relationship between percent open area (or hole size) and sensitivity.

Charlie: I think the wavelengths we're working with are so long (17 mm at 20 KHz) compared to the holes in perforated steel stators, or to the diameter of the wires in stretched wire stators, that thinking in terms of reflections off the contours may not be very useful. I don't know, though, whether there's any difference in the two stators' tendency to introduce turbulence (if that's the right term in this context). Any experts in fluid dynamics reading this?

Few

Capacitors with perforated plates have roughly the same capacitance as those with solid plates as long as the holes are small compared to the plate separation (and as long as we're limiting the discussion to signals whose wavelengths are large compared to all the other dimensions under consideration). Since ESL panels are basically capacitors, capacitors' insensitivity to the details of small perforations in their plates seems pertinent, but I don't know how to quantify the relationship between percent open area (or hole size) and sensitivity.

Charlie: I think the wavelengths we're working with are so long (17 mm at 20 KHz) compared to the holes in perforated steel stators, or to the diameter of the wires in stretched wire stators, that thinking in terms of reflections off the contours may not be very useful. I don't know, though, whether there's any difference in the two stators' tendency to introduce turbulence (if that's the right term in this context). Any experts in fluid dynamics reading this?

Few

good point ,few, i have been playing with some of the java applets on falstad.com to try and see what the effects might be. but haven't come up with anty thing solid yet.how ever they are very cool and helps you to under stand the basic principle of wave propagation. jer

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Perf stator options: opinions, please?