For optimum efficiency of bass waves from PRs vs active radiator...would it best for them to be coplanar so that it minimises nodal interference? Eg front facing AR and rear facing PR with 2 x Xmas?

Makes no difference, but it's worth considering using 2x passives on the sides of an enclosure to force cancel (equal but opposite movement of mass).

Makes no difference

Given the frequencies which a PR reproduces they ar eall omnidirectional. It matters not which way they ar eoriented.

But, as badman points out, anytime you can load woofers or PRs in push-push you make big gains (they have to be tightly coupled).

dave

Thanks for the reply; I guess Im thinking in terms, not of directionailty but of simply radiant LF energy; collision between non planar waves would produce diffusion and nulls/doubles much more than planar? With the small difference ie width of enclosure, the phase deccorrelation would always be constant (far less than 120hz cutoff of approx 3m) and predictable for DSP control?

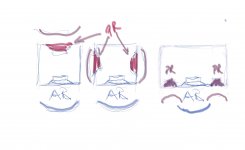

Assuming I have that wrong...could you provide any feedback on the attached pic as to the characteristics one would expect by the different PR placement (re: 2 x pr for advantage)

Cheers

Assuming I have that wrong...could you provide any feedback on the attached pic as to the characteristics one would expect by the different PR placement (re: 2 x pr for advantage)

Cheers

Attachments

That is a distance to wall thing. Often wall proximity can be used for a bit more extension.

dave

dave

^^ badman and dave are correct; at bass frequencies the wavelengths are so long that the enclosure will effectively be omnidirectional, so it won't matter which side they are on. Opposite sides for the PRs is good, as has been pointed out, but put them on the sides, not the top/bottom as they may sag due the the weight of the 'cone' passively pulling on the suspension. This may reduce Xmax.

thanks to all...got it

the pic was not actually wall prox/location but 3 different 'piston' orientations.

Would anyone know of a comprehensive resource to learn more about pr push push?

Cheers

the pic was not actually wall prox/location but 3 different 'piston' orientations.

Would anyone know of a comprehensive resource to learn more about pr push push?

Cheers

Last edited:

So the 3rd example (right hand side) with PRs on same face as active is also no less functional than the other examples? Sorry just making 100%.

Ignoring the lack vibration cancelling, correct; consider the size of the highest used frequency at full gain that will sum, i.e. the 1/4 WL distance between the PRs.

Example: single 12" between dual 12" PRs = ~26" min. on centers = ~13543"_sec/pi/26" = ~166 Hz, normally well above a woofer's gain [tuning] bandwidth [BW].

From this we see that we can space them much further apart if desired and still meet the 1/4 WL rule for near enough summing as one large PR with a ~1.4142x larger effective diameter.

GM

Example: single 12" between dual 12" PRs = ~26" min. on centers = ~13543"_sec/pi/26" = ~166 Hz, normally well above a woofer's gain [tuning] bandwidth [BW].

From this we see that we can space them much further apart if desired and still meet the 1/4 WL rule for near enough summing as one large PR with a ~1.4142x larger effective diameter.

GM

Last edited:

Thanks GM, yeah that makes sense. Im only looking at 125hz so its a little above basic fundamental 1st harmonic (most tuned kicks are max 60hz). I went to Edinburgh Military Tattoo, took some test stuff (on my phone) as you do, interesting that all the really sweet bass drum notes were no greater than 55hz...of course the acoustics of the venue would affect but 52hz translated the best at that distance. I was probably min 50m away, max 200m.

thanks to all...got it

the pic was not actually wall prox/location but 3 different 'piston' orientations.

Would anyone know of a comprehensive resource to learn more about pr push push?

Cheers

Not much to learn really- just design a box as-normal, for 2 PRs, then slap them on the sides, and make sure you have some bracing between their frames (or at least very, very near the mounting points). There are more nuanced aspects but those are on a case-by-case basis, and generally don't mean a whole lot with PRs. Better to design your enclosure, with detailed drawings, then ask for advice on your specific use case.

Not much to learn really- just design a box as-normal, for 2 PRs, then slap them on the sides, and make sure you have some bracing between their frames (or at least very, very near the mounting points). There are more nuanced aspects but those are on a case-by-case basis, and generally don't mean a whole lot with PRs. Better to design your enclosure, with detailed drawings, then ask for advice on your specific use case.

I just wanted to understand why...I have a lot more freedom than a box 🙂 I did an experiment using our machinery and casting an oblique ovoid enclosure which blew me (and some other mix engineers) away. As part of that process I wanted to see if it helped a sub as well. Before committing to that; I wanted to at least understand enough to be dangerous. The process lets me work a long way outside MDF/linear mindset. The mention of push push isnt really clear to me ie as to why it has extra benefit hence the question and search for a deeper understanding. Any efficiencies are appreciated.

Thanks again for your help

Subs is where it's needed most due to the [much] heavier PR diaphragms required with decreasing frequency, hence needs an ever increasing mass/rigidity to maximize as much electro-mechanical-acoustical efficiency as practical, i.e. stable/near non-resonant work platform.

If we instead divide its mass air load in two and wired in phase and in acoustic parallel [push-pull], then they in theory completely cancel out their vibration modes and the cab needs only a fraction of a single's cab mass/rigidity, though of course there's always at least a little bit of difference between drivers [air mass load], especially in room, so generally only allows a partial reduction, i.e. as stiff/massive as its active driver in a low vent mach ported box.

GM

If we instead divide its mass air load in two and wired in phase and in acoustic parallel [push-pull], then they in theory completely cancel out their vibration modes and the cab needs only a fraction of a single's cab mass/rigidity, though of course there's always at least a little bit of difference between drivers [air mass load], especially in room, so generally only allows a partial reduction, i.e. as stiff/massive as its active driver in a low vent mach ported box.

GM

Thanks GM; so we are really talking mechanical resonance benefit? makes the picture clearer. The material Im using is very high damping as it dives into more kinetic waves ie <250hz and the ovoid shape (in a full range + some bits) is practically non resonant. Just a small enclosure (Im using a focal flax 8" in a 10L asymmetric oblique ovoid) weighs about 15kgs alone. I understand that the shape theory wont really apply in the same magnitude for a sub. My performance target is 35-40hz with steep roll off. Im mainly mixing music but some soundtrack. When I go below 40, I use a tactile transducer fixed to my chair...I find it far easier to reference based on feel below 40hz

Last edited:

This is primarily the same thing seen from different points of view. Eg if you have each stereo speaker produce a high frequency tone and measure from half way between them, you still see +6dB even though a lot is happening elsewhere.I guess Im thinking in terms, not of directionailty but of simply radiant LF energy; collision between non planar waves would produce diffusion and nulls/doubles much more than planar?

- Home

- Loudspeakers

- Multi-Way

- Passive Radiator Projection Angle/face