Really struggling with this one. I've read Radio Designers 4, Wolpert, Poppovitch and other source material, non the wiser. Could someone tell me what is the equation I need & what are the various parameters I need to know please?

So far I've figured out Vpri & Ipri, Vsec & Isec and Lpri of a 25W PP OPT with a Zpri of 4k & Zsec of 8r. I figured I'd need an L of 63.69 for a 3dB loss or 127.38 for 1dB. I then pulled a load of spec sheets for "typical" laminations. This is where it gets tricky. I have 4 sets of laminations with bobbins, one set I know is Goss, the others, Bog knows. All lams are about 0.3mm thick. The only other spec I can find for a UK supplier of Cores is "thickness 0,35 mm, 50 Hz, 17.000 Gauss" or 1.7T: not much to go on.

So how the hell does one work out how many turns one needs on the pri to get L whatever with laminations of Bog knows what type of steel? Is there a rule of thumb?

Andy.

So far I've figured out Vpri & Ipri, Vsec & Isec and Lpri of a 25W PP OPT with a Zpri of 4k & Zsec of 8r. I figured I'd need an L of 63.69 for a 3dB loss or 127.38 for 1dB. I then pulled a load of spec sheets for "typical" laminations. This is where it gets tricky. I have 4 sets of laminations with bobbins, one set I know is Goss, the others, Bog knows. All lams are about 0.3mm thick. The only other spec I can find for a UK supplier of Cores is "thickness 0,35 mm, 50 Hz, 17.000 Gauss" or 1.7T: not much to go on.

So how the hell does one work out how many turns one needs on the pri to get L whatever with laminations of Bog knows what type of steel? Is there a rule of thumb?

Andy.

Yep, I thought of that after I asked the question. Strange how asking the question often reveals the answer. Thanks for your input.

After floundering around all day I found an equation in Popovitch Transformers for Tube Amplifiers L=N2 x uR x u0 x A/ "e" mp sorry not the exact characters. N2 is I presume number of turns squared, uR = permeability of material, u0 is absolute permeability, which is 1.257 to the power of 10 to the minus 8. A is area of core I think & emp is "the length of the mean magnetic strength"

That doesn't tell me the number of turns needed though, but as you imply, whack a load of turns on the core in question and measure it. Then comes the fun of trying to measure L.

And we haven't even gone into all the other mind bending parameters of an audio transformer, : ) Andy.

After floundering around all day I found an equation in Popovitch Transformers for Tube Amplifiers L=N2 x uR x u0 x A/ "e" mp sorry not the exact characters. N2 is I presume number of turns squared, uR = permeability of material, u0 is absolute permeability, which is 1.257 to the power of 10 to the minus 8. A is area of core I think & emp is "the length of the mean magnetic strength"

That doesn't tell me the number of turns needed though, but as you imply, whack a load of turns on the core in question and measure it. Then comes the fun of trying to measure L.

And we haven't even gone into all the other mind bending parameters of an audio transformer, : ) Andy.

Yes A will be the area of the metal of the core its a very standard equation. You should have much less of a problem measuring L with less turns when you not dominated by primary capacitance. Not sure where the 1.7T comes from is that the saturation flux. Anyway preaching to an expert.

Since you're interested in transformer winding, this site may be of interest:And we haven't even gone into all the other mind bending parameters of an audio transformer,

https://www.delatsch.com/

He can also be found on youtube, just search "delatsch".

A Tesla is AFAIK 10,000 gauss. The attached specs for ASCO C core is 17,000 Gauss, therefore 17,000 Gauss is 1.7T at 50hz. Hope that's right.Not sure where the 1.7T comes from is that the saturation flux.

What is the AL value? Inductance for X Area? For the Asco C cores? I'll attach other spec graphs for EI lams from a different supplier. What I'm trying to figure out is how I get the number of turns I need to wind to get x inductance & at the same time what laminations or C core to buy for an OPT of for example 4k pri with x inductance with a turns ratio of whatever.do they give an AL value?

From what I've read so far a few steps in the design of an audio tfmr is 1) figure out what Lpri you need for the LF response within certain parameters, then 2) figure out how to wind the OPT for the HF response etc. Like a lot of electronic engineering & life in general it's about compromise, cosmic balance, tit for tat, up & down. Somewhere in the middle is about right. Deep eh?

Re Delatsch thanks for link, I'm come across him whilst researching this subject but I'm more at home with pencil & paper than software.

Attachments

I am all for calculating ... and measuring.

Point being that although Math is exact, our "models" are, best case, iffy.

How do we know lamination material behaves like we expect? ..... except by measuring it.

Lots of manufacturing variations, different alloys, thermal processes, etc.

Personally I would design one transformer using "generic" data, then inject some DC at primary (simulating power tube imbalance), say 5 mA or even 10 mA and remeasure.

I can trust THAT 😄

Point being that although Math is exact, our "models" are, best case, iffy.

How do we know lamination material behaves like we expect? ..... except by measuring it.

Lots of manufacturing variations, different alloys, thermal processes, etc.

Personally I would design one transformer using "generic" data, then inject some DC at primary (simulating power tube imbalance), say 5 mA or even 10 mA and remeasure.

I can trust THAT 😄

The turns you need you have to figure them out from the power rating you need at a given induction. Is it PP or SE?Yep, I thought of that after I asked the question. Strange how asking the question often reveals the answer. Thanks for your input.

After floundering around all day I found an equation in Popovitch Transformers for Tube Amplifiers L=N2 x uR x u0 x A/ "e" mp sorry not the exact characters. N2 is I presume number of turns squared, uR = permeability of material, u0 is absolute permeability, which is 1.257 to the power of 10 to the minus 8. A is area of core I think & emp is "the length of the mean magnetic strength"

That doesn't tell me the number of turns needed though, but as you imply, whack a load of turns on the core in question and measure it. Then comes the fun of trying to measure L.

And we haven't even gone into all the other mind bending parameters of an audio transformer, : ) Andy.

P.S.

The core area in the formula is the effective area which takes into account the stacking factor. This 95% or 0.95 for EI lamination and 0.93 for C cores typically.

Last edited:

Whitlock wrote in "Audio Transformers" 1.2.1:I've read Radio Designers 4, Wolpert, Poppovitch and other source material, non the wiser. Could someone tell me what is the equation I need & what are the various parameters I need to know please?

Coil inductance increases as the square of the number of turns and in direct proportion to the permeability of the core and can be approximated using the formula:

L = 3.2* N*N * mu * A / (10exp8 * l )

where L = inductance in Henries,

N =number of coil turns,

mu = permeability of core,

A = cross-section area of core in square inches,

l = mean flux path length in inches.

Attachments

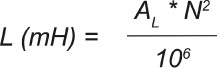

If you make -for example- 100 turn wire on undefined transformer core and measure inductance (Lx), the AL may calculating:What is the AL value?

AL=Lx / N^2 (where N=100).

If you know the AL parameter, primary inductance of OPT roughly calculating:

L=AL* N^2

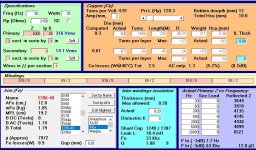

OPT_da doesn't work for me (Win10 64 bit).

I'm getting an error in the "windings" window and no results at all in the "copper" window.

I'm getting an error in the "windings" window and no results at all in the "copper" window.

Thanks.Try my version (extended cores and wires).

comdlg32.oxc acts up. My french is non existent, but the dialog box says missing or corrupt ocx file.

I've tried both the 32bit and 64 bit versions placed in the OPT_ad folder but no luck so far.

On the download site for the comdlg32.ocx it says to place the ocx file in the same folder as the rest of the program, or;-place the 64 bit version in the system32 folder or the 32 bit version in the sysWOW64 folder, which sounds downright wrong.

1.7T: not much to go on. One will never find this level in tube amp output trannies.

-----------------

Radiotron Hd Bk 4th ed P.206 onwards has an in-depth thesis on output trannies and relevant formula.

However, to put the spanner in the expectations of actual Bmax; the original Mullard 20W o/p tranny is quoted with a primary self inductance of 72H at 5V 50Hz excitation and at 10V 50Hz is 120H. The maximum flux density to keep natural core distortion (H2) lowish 1.5% (no nfb), equates to approx 5800 gauss or 0.5T at 20Hz 500V peak. The core cross section is 25cm2 using 150x125mm E&I laminations. From this we can deduce the core stacking height at approx 50mm. Quite a large core for 20W but capable of 20Hz with ease. From this we can roughly deduce an output transformer designed for 40Hz, wound with the same equation criteria, the core will be half the size, and so on.

For mains transformers 1.7T is to be avoided whatever reasons, that is reserved for industrial. Mains trannies for audio work, 1 to 1.2T for E&I types and often 1.6T for toroids often reduced for low leakage flux. Quite often, the 6.3V heater winding will determine the turns ratio integer to the number of primary turns relative to desired mains voltages, with core size a variable. There´s no refuge out of physics & the equations. Sorry. .........Bench Baron

Thanks for all the other idea's, i'll do some experimenting in the next few days & report back.

Andy.

Andy.

- Home

- Amplifiers

- Tubes / Valves

- Output Transformer Primary Winding - Calculating the Inductance.