Sch3mat1c said:In that case, I would imagine the primary sources of heat (sweep tubes are usually beam tetrodes, so there are two large hot spots on opposite sides of the plate) are best in a horizontal plane, since then the air flowing the fastest crosses these areas, cooling them more effectively. If they were vertical, the bottom side would be pretty well cooled by the fresh air while the top side would overheat because it's getting the already heated air.

Exactly. It's only beam valves that have a preferred orientation for losing heat. Otherwise, it doesn't hurt to align grid wires vertically (so that they can't sag onto the cathode), but heater wiring etc is usually the final arbiter..

Line O/P valve orientation

Ive seen many PL509/519 both virtically and horizontally mounted With the horizontal ones, the cathode larger sides were always vertical as would be the grid/beam-forming plates, there would be less chance of a grid wire sagging in this orientation.

I never changed a bad '509 in this orientation, but the efficiency diode used in the same position used to go heater cathode short sometimes, in various sets, ( sagging heater eventually shorted.)

Ive seen many PL509/519 both virtically and horizontally mounted With the horizontal ones, the cathode larger sides were always vertical as would be the grid/beam-forming plates, there would be less chance of a grid wire sagging in this orientation.

I never changed a bad '509 in this orientation, but the efficiency diode used in the same position used to go heater cathode short sometimes, in various sets, ( sagging heater eventually shorted.)

Too true........GEC recommended their tubes be mounted in a way that the anode heating power was at right angles to one another, also it was well known that with high loading conditions and heating power in the horizontal position the internal grids would gradually sag over time... .

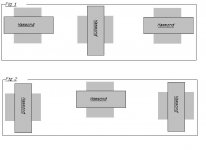

GEC app note No 3. Suggests advantage with pair KT88's on the conventional vert mount, pins 8-4 and 8-4 be in a straight line and on the horiz pins 2-6 and 2-6 in a straight line with 4 inches between centres. Don't trust this pin convention with other power tubes, my 6550's are different.

🙂rich

GEC app note No 3. Suggests advantage with pair KT88's on the conventional vert mount, pins 8-4 and 8-4 be in a straight line and on the horiz pins 2-6 and 2-6 in a straight line with 4 inches between centres. Don't trust this pin convention with other power tubes, my 6550's are different.

🙂rich

el84 newbie

i am planning a small stereo amp using ecc 81 and el84s (4 per channel PPP - AB1).

how close can the tubes be?

do these tubes lend themselves to horzontal or even 45 deg. installation?

can any suggest a compact layout? a jpg or 2 would do fine.

i am planning a small stereo amp using ecc 81 and el84s (4 per channel PPP - AB1).

how close can the tubes be?

do these tubes lend themselves to horzontal or even 45 deg. installation?

can any suggest a compact layout? a jpg or 2 would do fine.

how close can the tubes be?

About as close as half an inch, but in the case of compact wiring underneath around the sockets, I would suggest you keep it to one inch or wider...

I've seen 6BM8's all the time at 1inch or lower distance from each other. (ECL82 is the relative)

Which brings up another point, I don't think there is any noise issue with having two 'sides' of valves close together as I've seen SE designs with 9 pinners in desk plastic/bakelite stereo sets and they have no "crosstalk" to speak of.

People care to oppose? 🙂

Transformers are however a whole other can o' worms

If you have lots of ventilation on an open chassis, you can put the EL84 at the edge with only 1" between the envelopes (like the Leak Stereo 20). Move them towards the middle of the chassis, or towards one another, or put a cover on, and you are asking for a shortened lifetime due to excessive heat.

thanks guys. the leak 20 uses EL84s? I might put a cover on but it would be ventillated either slots from the sides or a mesh. just to keep prying hands out. BTW how close can the trannies be?

Keep trannies as far away from each other as possible, and transformers are like polarised magnets so face one south north and one east-west to prevent the wirings inside from interfering with another transformer which is facing the same way.

Same goes for chokes, power transformers and matching trannies.

Same goes for chokes, power transformers and matching trannies.

Attachments

i thought about that too. i happen to have trannies that have different mounting orientations so my guesss is one will be in teh x axis, the 2nd in the y axis and the 3rd in the z axis.

what is a reasonable distance? 2"?

what is a reasonable distance? 2"?

If they are perfectly at right angles (unlike the diagram above) then you can almost touch them, but one transformer's worth of separation helps greatly.

(The transformers in the diagram are not at right angles because a line drawn between centres is not at right angles to the coils.)

(The transformers in the diagram are not at right angles because a line drawn between centres is not at right angles to the coils.)

Two output transformers may be located side-by-side with only a couple of inches between them. It is important that the power transformer be located as far from the output transformers as possible and that the orientation be rotated 90 degrees.

is that why i see that most amps have the output trannies on either side of th power tranny? will this config be acceptable?

The topic is on vertical vs. horizontal orientation and my question is about mounting tubes upside down. I have seen guitar amps with tubes mounted so. Are there any guidance or restrictions to mount, say E180F / 6J9P tha way?

Edit.

Found another thread - sorry for an OT.

http://www.diyaudio.com/forums/tubes-valves/39038-mounting-tubes-upside-down.html

Edit.

Found another thread - sorry for an OT.

http://www.diyaudio.com/forums/tubes-valves/39038-mounting-tubes-upside-down.html

Last edited:

Commentators here suggest that valves mounted horizontally (or even upside down) are fairly common. I want to mount horizontally, so I did this: [Google Images "valve amplifier"]. On the first page, there was only one amplifier I could identify as having horizontally mounted tubes. They do not appear to be common in the first instance, at least not for modern amplifiers...

Commentators here suggest that valves mounted horizontally (or even upside down) are fairly common. I want to mount horizontally, so I did this: [Google Images "valve amplifier"]. On the first page, there was only one amplifier I could identify as having horizontally mounted tubes. They do not appear to be common in the first instance, at least not for modern amplifiers...

In modern amplifiers the tubes are also a fashion statement, and as such are showcased prominently. In the old days they were simply all there was to get the job done, and were often inside the chassis to minimize noise pickup, burnt fingers, and wiring paths.

In modern amplifiers the tubes are also a fashion statement

Exactly, you've hit the valve on the head. Fashion's raison d'etre is to be different, to provoke an emotional response and to differentiate it /yourself from the mundane. Sticking vertical tubes at the front with a few transformers at the rear, atop a shiny box seems (dare I say) boring. It may be style but IMHO, it's not fashion.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- Orientation and Horizontal Mounting