At long last I have extracted the digit and setup a dedicated Test and Measurement bench in my two car concrete floored steel garage (Mobile phone and AM radio reception is lousy).

The 240V supply comes via 45m buried conduited cable into a garage wall mounted breaker box - earth arrangement/wiring is unknown at present.

I have a standard waist height bench for the DUT, and a shelf 450mm above for Signal Generators, D&N meters, USB sound card etc.

I also have a Kikusui PCR500L variable voltage/variable frequency power regenerator.

Sig gens have transformer isolated floating output, and D&N sets have switchable transformer isolated floating input/chassis earth referenced input.

Monitor outputs are chassis earth referenced.

I am able to drive an earth stake outside the shed directly behind the bench allowing earthing conductor length of as short as 1.5m, and I am prepared to drive more stakes if required/advantageous.

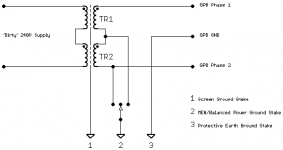

I have a dozen 300VA 240V medical grade screened isolation transformers and am prepared to use one per test equipment device and as many as required for the system/device under test.....IOW I am prepared to power each GPO from it's own isolation transformer.

I also have a length of 1/2" copper pipe intended perhaps as signal side earth common.

Now the questions...

Is it worthy to connect the isolation transformer screens to a second dedicated earth stake, with equipment protective/chassis earths connected to the first earth stake ?.

Should the isolated 240V power run fully floating, or should one side be locally grounded providing A & N phases ?.

I am setting out to measure low level low frequency wideband noise and 1/f noise over quite long periods if necessary.

Any advice/comments on optimal bench power/signal wiring will be much appreciated.

Dan.

The 240V supply comes via 45m buried conduited cable into a garage wall mounted breaker box - earth arrangement/wiring is unknown at present.

I have a standard waist height bench for the DUT, and a shelf 450mm above for Signal Generators, D&N meters, USB sound card etc.

I also have a Kikusui PCR500L variable voltage/variable frequency power regenerator.

Sig gens have transformer isolated floating output, and D&N sets have switchable transformer isolated floating input/chassis earth referenced input.

Monitor outputs are chassis earth referenced.

I am able to drive an earth stake outside the shed directly behind the bench allowing earthing conductor length of as short as 1.5m, and I am prepared to drive more stakes if required/advantageous.

I have a dozen 300VA 240V medical grade screened isolation transformers and am prepared to use one per test equipment device and as many as required for the system/device under test.....IOW I am prepared to power each GPO from it's own isolation transformer.

I also have a length of 1/2" copper pipe intended perhaps as signal side earth common.

Now the questions...

Is it worthy to connect the isolation transformer screens to a second dedicated earth stake, with equipment protective/chassis earths connected to the first earth stake ?.

Should the isolated 240V power run fully floating, or should one side be locally grounded providing A & N phases ?.

I am setting out to measure low level low frequency wideband noise and 1/f noise over quite long periods if necessary.

Any advice/comments on optimal bench power/signal wiring will be much appreciated.

Dan.

Driving extra earthing rods increases the risk of lightning damage.

Talk to a commercial installations Electrician to find a SAFE way to do this.

Many/some commercial and industrial installations have a mesh/net of earthing rods interlinked and testable to maintain a common EARTH potential even in the event of a nearby lightning strike.

Talk to a commercial installations Electrician to find a SAFE way to do this.

Many/some commercial and industrial installations have a mesh/net of earthing rods interlinked and testable to maintain a common EARTH potential even in the event of a nearby lightning strike.

Last edited:

Not a problem in this case...I am not altering the existing wiring and additionally all gear will be unplugged when not in use.

The idea here is to provide a local isolated power distribution with it's own earthing scheme optimised for low 240V borne noise.

Dan.

The idea here is to provide a local isolated power distribution with it's own earthing scheme optimised for low 240V borne noise.

Dan.

- Status

- Not open for further replies.