I am using ff85wk in Planet 10's great uFonkenwk. I'm hearing a little bit of harshness and would like to do something. Due to financial constraints and/or

lack of skill to do it myself, I am unable to do the enable treatment. Would I be better off leaving them stock or would I at least see some benefit with one or two light coats of Mod Podge? Please understand this is in no way a put down of Planet 10's time consuming process. Thanks for any suggestions.

lack of skill to do it myself, I am unable to do the enable treatment. Would I be better off leaving them stock or would I at least see some benefit with one or two light coats of Mod Podge? Please understand this is in no way a put down of Planet 10's time consuming process. Thanks for any suggestions.

Member

Joined 2009

Paid Member

Well, it’s a tough thing to tame, as it could also be coming from your amp or source and not the speakers. It would be good if you have first eliminated this possibility.

I'm listening on a nicely restored pair of Heathkit W3M tube amps. I don't think that is the problem.

That's one of the smoothest little drivers of it's type on the planet. Never heard them sound harsh, and that's driven buy a lot of different amps.😕

jeff

jeff

Last edited:

Might be more info here: what am I not getting about the FF85WK

Try some different amps would be my first suggestion.

Try some different amps would be my first suggestion.

Ditto. If not possible, and assuming your current amplifiers have the grunt, pull your speaker wire and replace with a single strand of 30ga magnet wire per leg (not that they're really independent legs but you know what I mean). Be careful; it's fragile & this is an experiment only.

Distributed loop resistance can have some interesting effects. It will change the effective system Q; perhaps more interesting is the potentially reduced peak current handling of the thin wire. For want of a better phrase, it can clip LF dynamic peaks, which tends to cause greater perceived clarity in the mids & HF. It's pure sleight of hand, & depends on the loop length, amplifier / speaker load details etc., but it can happen that way. Conversely, depending on exact configuration (don't twist the wires -that enamel coating is very thin) it can also damp the HF down a bit -combination of resistance & a touch of added inductance with a wider spacing between the conductors. Costs very little to try -just be careful if you bob down to the local electrical store. We're still in a pandemic after all.

Distributed loop resistance can have some interesting effects. It will change the effective system Q; perhaps more interesting is the potentially reduced peak current handling of the thin wire. For want of a better phrase, it can clip LF dynamic peaks, which tends to cause greater perceived clarity in the mids & HF. It's pure sleight of hand, & depends on the loop length, amplifier / speaker load details etc., but it can happen that way. Conversely, depending on exact configuration (don't twist the wires -that enamel coating is very thin) it can also damp the HF down a bit -combination of resistance & a touch of added inductance with a wider spacing between the conductors. Costs very little to try -just be careful if you bob down to the local electrical store. We're still in a pandemic after all.

That's one of the smoothest little drivers of it's type on the planet. Never heard them sound harsh, and that's driven buy a lot of different amps.😕

Jeff,

I’d guess you have only heard FF85wKeN.

There are a number of mods i do to these before i EnABL them.

1/ 2 coats of ZIG 2-way glue at the interface of the surround and the cone on the back of the cone.

2/ a thin as possible coat of ModPodge/Puzzlekoat (slightly thinned). Do not do the dustcap. With this step one can add some colour (food colouring) to the modPodge.

3/ The dustcap, while the source of the extended top, does ring somewhat. I have a specific pattern that can be added that seems to work well taming this. It is (sort of) EnABL, but because it is aluminium, if careful, a Q-tip one can clean up mistates and try again. (and maybe some isopropanol if you have to try many times) After this a 50% thinned single coat of gloss. To minimize the tendency of the dustcap to repell the gloss on eshould carefully wipe the dustcap with alcohol before starting.

4/ if you are not comfortable doing the spots a coat of gloss would likely help by itself.

5/ if you want ot go further the cone is now ready for EnABL. If anyone wants to tackle that i am happy to help. The last step in EnABL is to do 2 thin coats of gloss. If you do not plan on doing spots, this might also help.

Do note that there are 3-ringsets near the surround. With EnABL there is usually only 2. Here the 3rd ring, over the surround/cone interface, is intended to complement what is done in step 1.

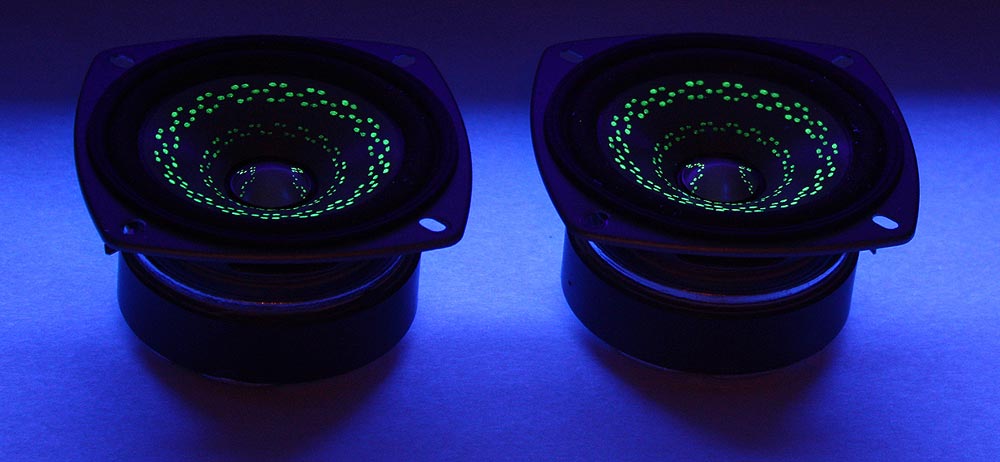

And here a picture that shows the spots on the dustcap clearer.

Do note that the A5.3 is an A5.2 with a different shape voice coil wire, primarily a marketing thing for the Japanese market.

While stock A5.2/3 are a bit smoother than the FF85wk, in an afternoon of comparison i couldn’t really tease the FF85wKeN apart from the A5.2eN (and A5.3eN is also pretty much indistinguishabe form A5.2eN).

Add woofer(s) to help these along as the OP has, and you have a system with capabilities that leave few excuses.

dave

Last edited:

It would be interesting to see some detailed measurements taken by a calibrated mic to see the before and after delta, is this data available?

Thanks ��

Thanks ��

Thanks Dave for the detailed explanation. I'm not brave enough to try the spots so I'll just go with coat of Mod Podge and Zig glue if I can find it. Thinking of building a triangular unit the same size as the integrated one on the Tysen to sit on top of my bass cabs.

Michael’s here in Canada.

EK Success(R) 2-Way Squeeze and Roll Glue Pen

Mod Podge(R) Gloss | Michaels

dave

EK Success(R) 2-Way Squeeze and Roll Glue Pen

Mod Podge(R) Gloss | Michaels

dave

Thanks Dave. I did one coat of Mod Podge and can already hear a difference. I'm a retired public school band director and listen to a lot of brass, wind ensemble, and orchestral music in addition to the usual "girl and a guitar" recordings. I can see that I need to be careful as to how hard I push these. Until the pandemic I also did a lot of recording of public school groups at contests and festivals. I have to guard my hearing. PS. I'm not dissing the "girl and a guitar" stuff. I have lots of faves in that genre also. Stay safe. Thanks again.

The 9.5kHz peak which causes sibilance is caused by the cone itself, not the dustcap. Run the maths on the diameter of the dustcap and the lowest frequency it can ring at is about 20kHz.

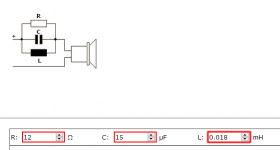

Easiest way to fix is to build yourself a 9.5kHz passive RLC notch filter. This way the modification is fully reversible. edit: notch filter attached. Increase the value of the resistor to make the notch deeper, decrease towards 0ohm to make it shallower (at 0ohm, the filter doesn't do anything)

Easiest way to fix is to build yourself a 9.5kHz passive RLC notch filter. This way the modification is fully reversible. edit: notch filter attached. Increase the value of the resistor to make the notch deeper, decrease towards 0ohm to make it shallower (at 0ohm, the filter doesn't do anything)

Attachments

Last edited:

Suggestion on where to get inductors that small. I'm in USA and mainly deal with Parts Express and Madisound. Round the value you gave to common size? Thanks.

Easiest way to fix is to build yourself a 9.5kHz passive RLC notch filter.

RLC is a bandaid. The Zig on the back (and the extra EnABL ring) work to discourage this peak.

dave

Make some by turning some wire around a wooden dowel. Small inductors are easy to make by hand because they require relatively few turns.Suggestion on where to get inductors that small. I'm in USA and mainly deal with Parts Express and Madisound. Round the value you gave to common size? Thanks.

Air Cored Inductor Calculator – M0UKD – Amateur Radio Blog

Without an inductance meter you may need to get creative at tuning the filter to be exactly 9.5kHz. You could aim to make the 15uF capacitor a little under the nominal value (14uF), then play a 9.5kHz test tone and add small capacitors (0.1uF) in parallel until the tone becomes quietest.

Do you have measurements to back up this claim? What happens if you over-do it (the driver is junked)? In my experience, painting cones usually just moves problematic peaks to different frequencies. In a lot of cases things become worse, or the amount of mass required to sufficiently damp kills the drivers sensitivity. If there was an easy solution to damping cone breakup every manufacturer would do it.RLC is a bandaid. The Zig on the back (and the extra EnABL ring) work to discourage this peak.

dave

Last edited:

I’d guess you have only heard FF85wKeN.

You may be right. It's possible I've never heard a stock driver. Didn't realize that there was significant issues with this driver that needed attention. The fr plot looks very good compared to many other Fostex drivers. The off-axis treble rolloff confirms what they were like on my desktop.

jeff

Hi Dave.

I am willing to try Enable FF85wk.

I would like to have picture of 1/2 coat of zig2way glue paint.

Also I want to try dott painting by puzzle coat.

What is the radius if I make a circle of paper for template?

I am willing to try Enable FF85wk.

I would like to have picture of 1/2 coat of zig2way glue paint.

Also I want to try dott painting by puzzle coat.

What is the radius if I make a circle of paper for template?

I have been busy for the last couple days. This subject requires needs a careful dissertation.

First, you need to collect the appropriate raw materials.

ModPodge, ZIG 2-way glue for the preprep. High solids train paint for the spots and the clear glosss (used for covering decals on models). You will need an A5, and #56 caligraphy nibs. And some 99% isoproponal to take whatever residue is on the dustcap before adding anything (otherwise it does not stick). Being in Japan the NA brands may be hard to find, there will be equivalents.

The FFxx5wk you will note have 3 rings at the periphery instead of the usual 2. The one closest to the surround are to help ameriolat esome surround/cone resonaces (that the 2-way glue also works to address). Then there is a ringset near the dustcap (i’ll have to measure that template, and th eunique pattern on the dustcap. I will dig out the template for that.

dave

First, you need to collect the appropriate raw materials.

ModPodge, ZIG 2-way glue for the preprep. High solids train paint for the spots and the clear glosss (used for covering decals on models). You will need an A5, and #56 caligraphy nibs. And some 99% isoproponal to take whatever residue is on the dustcap before adding anything (otherwise it does not stick). Being in Japan the NA brands may be hard to find, there will be equivalents.

The FFxx5wk you will note have 3 rings at the periphery instead of the usual 2. The one closest to the surround are to help ameriolat esome surround/cone resonaces (that the 2-way glue also works to address). Then there is a ringset near the dustcap (i’ll have to measure that template, and th eunique pattern on the dustcap. I will dig out the template for that.

dave

- Home

- Loudspeakers

- Full Range

- Opinions on Mods to FF85wk