Hi Mooly. Yes...this thread is a spin off from the recent thread I created called "RIAA pre-amp Spot the mistake". The pre-assembled board came with lm4562s fitted but the filter section had a pair of wrong capacitors fitted. After correcting the components, I had a problem with "popcorn noise"...I fitted ne 5532s to test but ended up with 10.5V DC offset at the output. I also fitted new LM4562s and the DC offset like the originals is just under 1V or so, which I have to say is OK as long as I fit a blocking capacitor which the board maker had obviously omitted because he simply copied the Texas design and presumably never thought about the DC offset might be incompatible with other pre-amps that are DC straight-through designs. So after I came across 2x new OPA2134s I thought I would fit then to compare their resultant offsets in this design...the result is about half the level of the LM 4562s so I still need the DC blocking capacitor. I was thinking that if I choose a value that is not too big the roll off might act as a basic rumble filter anyway?....My pre-amp input impedance is specified as 20Kohm and 450pf (assume extra 200pf for connecting cable) . I wonder what capacitance I would need to get a flat response down to 20Hz and roll off after that? The LM4562 can drive 600 Ohms. I've seen fairly similar designs use 10uf but obviously that value will have to be an electrolytic due to size constraints.Have you actually tried an LM4562? which is what the design is aimed at. That chip does have a much lower input offset voltage and also very low input bias currents. It may well be acceptable with that device.

The roll off with a cap would not be steep but it would block DC. You can add a cap in the feedback return which would give a precisly defined roll off. Adding a cap at the output would be influenced by load impedance which isn't great design practice really.I wonder what capacitance I would need to get a flat response down to 20Hz and roll off after that?

If you want essentially zero offset but no output coupling cap then you need to AC couple both opamps feedback network. If a small DC offset is acceptable then you can just AC couple the second opamps network which would give unity gain to DC passed from the first stage.

This maintains response to 20Hz but I wouldn't like to say if it would be considered a good solution for a phono stage.

Thanks again Mooly. I very much appreciate all your help you are giving me. The feedback method is new to me, perhaps I would use that if starting afresh however as the board is quite tight I think I will simply add a DC blocking capacitor at the output, this will remove all the DC and act as a crude form of rumble filter but fortunately the direct drive Technics SL1500 has an inaudible amount of rumble and the records I have all seem pretty good as far as warps and recorded rumble so not having a filter is OK on my set up. So, I'll refit the LM4562s and incorporate the new 10uf capacitors. This will do for now. The warm weather currently means I've got nearly 2 acres of grass to mow and time is limited. Thanks very much Mooly for all your help.... 🙂The roll off with a cap would not be steep but it would block DC. You can add a cap in the feedback return which would give a precisly defined roll off. Adding a cap at the output would be influenced by load impedance which isn't great design practice really.

If you want essentially zero offset but no output coupling cap then you need to AC couple both opamps feedback network. If a small DC offset is acceptable then you can just AC couple the second opamps network which would give unity gain to DC passed from the first stage.

This maintains response to 20Hz but I wouldn't like to say if it would be considered a good solution for a phono stage.

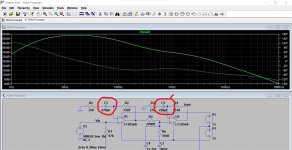

View attachment 1036465

AC coupling the feedback return sets the voltage gain of the stage to '1' at DC. You will see that methd used in 99% of power amplifiers for example.

I've a bit of grass cutting to do as well 😉 Four lawns but not two acres worth 😱 Would need a long mains lead for that.

I've a bit of grass cutting to do as well 😉 Four lawns but not two acres worth 😱 Would need a long mains lead for that.

This whole exercise started because of supposed popcorn noise.Thanks again Mooly. I very much appreciate all your help you are giving me. The feedback method is new to me, perhaps I would use that if starting afresh however as the board is quite tight I think I will simply add a DC blocking capacitor at the output, this will remove all the DC and act as a crude form of rumble filter but fortunately the direct drive Technics SL1500 has an inaudible amount of rumble and the records I have all seem pretty good as far as warps and recorded rumble so not having a filter is OK on my set up. So, I'll refit the LM4562s and incorporate the new 10uf capacitors. This will do for now. The warm weather currently means I've got nearly 2 acres of grass to mow and time is limited. Thanks very much Mooly for all your help.... 🙂

Since you mention to have a new LM4562, I’m curious to hear what happened to the popcorn noise while changing the opamp.

Hans

I’m surprised that a 10V offset was measured at the output while using a 5532.

The gain of the second stage was increased, so maybe overall DC gain is now 1000.

10Volt offset would almost mean 10mV input offset, way above the typical 5532’s specs.

I suppose you measured with open input, whereby the 47k and the 5532’s input current caused the large offset.

This is completely unrealistic since a Cart has a much lower resistance.

So better measure output offset with a shorted input.

Hans

The gain of the second stage was increased, so maybe overall DC gain is now 1000.

10Volt offset would almost mean 10mV input offset, way above the typical 5532’s specs.

I suppose you measured with open input, whereby the 47k and the 5532’s input current caused the large offset.

This is completely unrealistic since a Cart has a much lower resistance.

So better measure output offset with a shorted input.

Hans

Last edited: