Your kidding me arent you SDan? They look incredible I would assume this is the completed form and by that I mean you will no longer be testing and working on it will you? Either way I would love to speak to you.

They're beautiful. I'm really interested to see more details and listening impressions. I'm working on an omnidirectional speaker, though very different from yours and not nearly as cool looking.

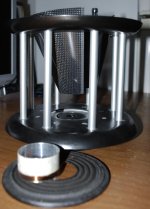

I built boxes to a carpentry workshop from 18mm MDF and i painted in black piano to a dye house.Height = 105cm, widht = 36cm, weight = 60Kg.It consists of 3 rooms.One of the largest is for bass 12 inches.Next is the resonance chamber at ~200 Hz (Helmholtz resonator) and the last is room for omnidirectional speaker.

My english is from google translate

My english is from google translate

Attachments

MBL ? anyone 🙂 nice looking and i trully wonder how they sound. verry nice result !!!!

why the Helmholtz resonator ??

why the Helmholtz resonator ??

Hey Sdan your english is pretty understandable given the method. How did you manage to replicate them? What sort of information was available to you. I know some about German physics They list plenty of information that allows replication. One interesting part is the cone you made very interesting using carbon fiber from experience I know it is a material with a learning curve. Could you explain how you did it? Would be interesting to compare measurements in other respects besides spl to Hz.

Hi WrineX, sorry for the late response. I see that you like electrostatic speakers. Even i was thinking about the next project that is sure electrostatic,and your data is interesting. Why the Helmholtz resonator ?? 200Hz is the frequency separation filter and thus reduce resonance box which is quite annoying at this frequency.This resonator + Hawaphon is found in the original project to reduce de walls vibration. In my project internal walls are painted with antiphon, added foam corrugated, and wool sound absorbing.

Magnasanti,to con i did many tests. Different types of resins and various materials. Best sound i got from carbon but disappointing aspect so i bought ready-made 0.2mm carbon from China . I built a stencil and i made carbon cone in the oven. When I have time I would put other measurements

Attachments

So if I understand you correctly you testes many combinations but were disappointed. What were you disappointed by? from the images the laminate at least on some doesn't seem great a problem with which I am familiar with. I assume the reason you chose to go and buy pre-made ones was to get more or less perfect laminates? Excellent effort thought I think you have tried more than double the amount I have made!

Walsh is using a combination of materials in their large models

HHR Exotic Speakers - Photos

Very nice Job.Speakerunits looks pro.

Bernt

HHR Exotic Speakers - Photos

Very nice Job.Speakerunits looks pro.

Bernt

So these are like the inverted cones of Ohm Walsh? They are not planar or electrostatic?

I was planning on making an Ohm inverted cone type planar speaker for over 500hz one day. looking at a Electrostatic version too....just need time...

I was planning on making an Ohm inverted cone type planar speaker for over 500hz one day. looking at a Electrostatic version too....just need time...

I dont believe that is walsh just s very experienced and knowledgeable diyer from I recall.Walsh is using a combination of materials in their large models

HHR Exotic Speakers - Photos

Very nice Job.Speakerunits looks pro.

Bernt

I do plan of doing a walsh clone sometime when time allows for. will be interesting to exchange information and measurements.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Omnidirectional sound