Hi Guys!

thanks up front!

On sale near me is a 110V VoM tape player that would make the perfect guitar amp:

1. all the right tubes 12AX7's, one 6V6

2. all the right secondary voltages 330, 5, 6.3, and it's center tapped.

So the problem is....... I live in a 240V area.

I saw on one site that if I wanted to rewind the primary to keep the secondary exactly as is, I would need twice as many windings. I'm going to assume that there's no room in there for 2X windings (Correct?).

I've also seen on this site warnings about not to run 240V through a primary designed for 120V, so I imagine that 240V requires thicker wires, making the space for twice the windings even worse. (Correct?)

So, short of buying a new power transformer or using a standard 240>120VAC transformer to place before the amp, what do you suggest I do?

thanks up front!

On sale near me is a 110V VoM tape player that would make the perfect guitar amp:

1. all the right tubes 12AX7's, one 6V6

2. all the right secondary voltages 330, 5, 6.3, and it's center tapped.

So the problem is....... I live in a 240V area.

I saw on one site that if I wanted to rewind the primary to keep the secondary exactly as is, I would need twice as many windings. I'm going to assume that there's no room in there for 2X windings (Correct?).

I've also seen on this site warnings about not to run 240V through a primary designed for 120V, so I imagine that 240V requires thicker wires, making the space for twice the windings even worse. (Correct?)

So, short of buying a new power transformer or using a standard 240>120VAC transformer to place before the amp, what do you suggest I do?

Your 240volt assumptions are mostly wrong.

You can buy universal mains transformers.

They have two primary windings. The simplest has two 115Vac windings.

For 110Vac to 120Vac mains supply you correctly connect the two 115Vac windings in parallel.

For 220Vac to 240Vac mains supply you correctly connect the two 115Vac windings in series.

A more complex (expensive) universal mains transformer still has two primary windings, but in addition there are intermediate taps to allow selection for different supply voltages.

eg.

one winding tapped at 0Vac, 110Vac, 115Vac and 120Vac.

The second primary is identical.

This allows you to connect to 110Vac, or 115Vac, or 120Vac, or 220Vac, or 225Vac, or 230Vac, or 235Vac, or 240Vac.

In all cases you must ensure that the windings are correctly wired before power ON !!!!!!

You would need to find out whether that amplifier has a single primary transformer, or a dual primary transformer. A photo usually tells the knowledgeable enough.

BTW,

For a single primary mains transformer, a 115vac winding has the same copper volume as a 230Vac winding of the same VA rating.

The 115Vac winding has fewer turns of thicker wire, whereas the 230Vac winding has double the number of turns using a wire of half the cross-sectional area. The resistance of the 230Vac winding will be roughly four times the resistance of the 115Vac winding.

You can buy universal mains transformers.

They have two primary windings. The simplest has two 115Vac windings.

For 110Vac to 120Vac mains supply you correctly connect the two 115Vac windings in parallel.

For 220Vac to 240Vac mains supply you correctly connect the two 115Vac windings in series.

A more complex (expensive) universal mains transformer still has two primary windings, but in addition there are intermediate taps to allow selection for different supply voltages.

eg.

one winding tapped at 0Vac, 110Vac, 115Vac and 120Vac.

The second primary is identical.

This allows you to connect to 110Vac, or 115Vac, or 120Vac, or 220Vac, or 225Vac, or 230Vac, or 235Vac, or 240Vac.

In all cases you must ensure that the windings are correctly wired before power ON !!!!!!

You would need to find out whether that amplifier has a single primary transformer, or a dual primary transformer. A photo usually tells the knowledgeable enough.

BTW,

For a single primary mains transformer, a 115vac winding has the same copper volume as a 230Vac winding of the same VA rating.

The 115Vac winding has fewer turns of thicker wire, whereas the 230Vac winding has double the number of turns using a wire of half the cross-sectional area. The resistance of the 230Vac winding will be roughly four times the resistance of the 115Vac winding.

Last edited:

If the mains transformer has a single 115Vac primary then the cheapest way to get it working correctly on 240Vac is to buy an auto-transformer that gives a 120Vac output for a 240Vac input.

An auto-transformer is NOT ISOLATING.

It can only be used to feed an isolating transformer, never for a non isolated PSU.

An auto-transformer is NOT ISOLATING.

It can only be used to feed an isolating transformer, never for a non isolated PSU.

Let's pretend that the only transformer in the world is the one found in the 110VAC tape player......

It was built in 1958.....

Are there any options to modify the current transformer to run on 240VAC?

It was built in 1958.....

Are there any options to modify the current transformer to run on 240VAC?

did you read any of the replies?

If it has a single primary winding for 110Vac, then that is the only mains voltage it can be used with.

If it has dual primary windings each rated at 110Vac, then you have many options.

Have a look at what is fitted.

If it has a single primary winding for 110Vac, then that is the only mains voltage it can be used with.

If it has dual primary windings each rated at 110Vac, then you have many options.

Have a look at what is fitted.

let´s pretend you are NOT building any kind of amplifier using those old parts.Let's pretend that the only transformer in the world is the one found in the 110VAC tape player......

so? 😕It was built in 1958.....

Are there any options to modify the current transformer to run on 240VAC?

It depends on who´s asking.

I do wind transformers commercially, have the proper winding equipment, stocks of wire in different diameters, mylar and pressphan insulating sheets in various thicknesses, transformer type paper electrical tape, insulating varnish, plus experience and knowledge to do that job so I can do it properly and safely.

Do you?

Last edited:

@ Alex:

I have read all the replies.

Please reread this part of my question:

I saw on one site that if I wanted to rewind the primary to keep the secondary exactly as is, I would need twice as many windings. I'm going to assume that there's no room in there for 2X windings (Correct?).

I've also seen on this site warnings about not to run 240V through a primary designed for 120V, so I imagine that 240V requires thicker wires, making the space for twice the windings even worse. (Correct?)

@JMF

I wrote the year of mfg. to help you answer my question of is there room to rewind the primary? I also wrote it to help you help me determine if they wound double primaries as Alex commented.

Are you suggesting that the only people who can rewind a transformer have all the equipment that you have?

The 1958 VoM tape recorder is about 60 non highway miles away and the owner is not willing to take it apart to take pictures of the transformer. It's not worth going there just to check it out.

I knew before I posted my questions that the cheapest/fastest method is to buy a transformer. Please see my original post where I asked for help with other answers.

So far no one has yet to answer my questions.

I have read all the replies.

Please reread this part of my question:

I saw on one site that if I wanted to rewind the primary to keep the secondary exactly as is, I would need twice as many windings. I'm going to assume that there's no room in there for 2X windings (Correct?).

I've also seen on this site warnings about not to run 240V through a primary designed for 120V, so I imagine that 240V requires thicker wires, making the space for twice the windings even worse. (Correct?)

@JMF

I wrote the year of mfg. to help you answer my question of is there room to rewind the primary? I also wrote it to help you help me determine if they wound double primaries as Alex commented.

Are you suggesting that the only people who can rewind a transformer have all the equipment that you have?

The 1958 VoM tape recorder is about 60 non highway miles away and the owner is not willing to take it apart to take pictures of the transformer. It's not worth going there just to check it out.

I knew before I posted my questions that the cheapest/fastest method is to buy a transformer. Please see my original post where I asked for help with other answers.

So far no one has yet to answer my questions.

Re-read post 4 - It answers your questions about winding space.

Also consider, the primary winding may well be in the centre of the transformer.

Meaning you would need to completely uncoil EVERY winding and start again with a bare bobbin.

Can someone answer me a hypothetical question -

can you use 2 - 110v primaries of a transformer to create an auto-transformer for this purpose (leaving the LV secondaries unconnected)?

Would you need to select the VA rating of the auto-transformer to match the VA rating of the main transformer?

Also consider, the primary winding may well be in the centre of the transformer.

Meaning you would need to completely uncoil EVERY winding and start again with a bare bobbin.

Can someone answer me a hypothetical question -

can you use 2 - 110v primaries of a transformer to create an auto-transformer for this purpose (leaving the LV secondaries unconnected)?

Would you need to select the VA rating of the auto-transformer to match the VA rating of the main transformer?

Russc,

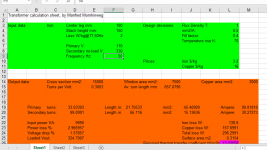

according to the spreadsheet I found on this page, Practical Transformer Winding

it seems that there's only 33 windings.....How bad could it be?

according to the spreadsheet I found on this page, Practical Transformer Winding

it seems that there's only 33 windings.....How bad could it be?

Attachments

...only 33 windings.....How bad could it be?

If I am reading that spreadsheet right: it is for a 100mmx150mm core. (The center leg, not the overall core.)

This is MUCH larger than you would find in a domestic tape deck. I'm not sure any domestic appliance would have a core 4 inches wide and stacked 6 inches high. The outside width would be like 12 inches or 300mm, and the height not a lot less.

No, for a 50VA-100VA core I would expect very-approximately 1,000 turns for 110V, and double the turns (in wire 0.7X the diameter) for 230V. That's a lot of de/re-winding. And frequently the line-side was inside.

I'd also expect mild extra heating from running a PT scaled for 60Hz on 50Hz. Sometimes the difference is negligible. I do not remember the VoM machines having generous transformers, and it could run hot, or need more math allowing more sag.

230V-115V transformers are not that expensive. At 100VA it can probably be tucked inside the speaker cabinet to avoid an extra lump to handle. The 60Hz-50Hz issue isn't solved, but can be checked without tedious rewinding and possible trouble.

Alternatively: 12AX7&6V6 _IS_ a Fender Champ. Champ/DeLuxe PTs are readily available in all line voltages. And likely more reliable (fresher, and modern shellac) than a PT from the Sixties.

You seem to selectively read only the line which "proves" your beliefs ... and conveniently ignore the rest.Russc,

according to the spreadsheet I found on this page, Practical Transformer Winding

it seems that there's only 33 windings.....How bad could it be?

Two lines below that you should have read that it´s a "9990VA" transformer, call it a 10KW one ... do you think you can even *compare* it to what´s powering a tape recorder?

And in fact it´s very conservatively rated, that core can actually handle 22kW ... even further away.

You probably have a #112 core there, some 28*28mm net section, or 7.84 cm squared.

You will then need (45/7.84)*220=1263 turns.

It´s customary to add 5% to compensate for core magnetization and losses, in any case very close to PRR´s estimation.

You will need at least a 6.3V 1.5 to 2A winding for filaments, plus 2 High Voltage ones . some 2200 to 3500 turns each.

That´s *basic* transformer winding equipment. 🙂Are you suggesting that the only people who can rewind a transformer have all the equipment that you have?

In theory you can wind that by hand, saving on the winding machine (good luck and lots of patience with that), but everything else (insulating sheets, varnish, tape, etc.) is still needed.

Even if you try to rewind it reusing old wire, the factors of age , crumbling old synthetic enamel (all they had way back then), 60 years old impregnation varnish and very fine wire gauge will conspire to damage wire insulation when you try to unwind it, certainly enough to make it unusable. (dangerous).

Unwinding of such old stuff in general is only done to "count turns" and measure wire gauge, also to record interleaving if used, but then you rewind with fresh wire.

All other comments by PRR and others apply.

Now that transformer may very well provide long years of service, if just left unmolested and fed 110V from an external autotransformer.

You seem to selectively read only the line which "proves" your beliefs ... and conveniently ignore the rest.

Sorry to disappoint you but I don't have any beliefs. I'm just asking for info without getting an attitude in return.

Neither am I conveniently ignoring anything. There's much I don't understand here.

Others seem to be willing to help without judgement.

Proving me wrong on this forum is like bragging that you can beat up a two year old. Nothing is proved.

If you want to help, thanks. Otherwise, please don't post.

In principle, yes. In practice, don't do it unless you know exactly what you're doing!Can someone answer me a hypothetical question -

can you use 2 - 110v primaries of a transformer to create an auto-transformer for this purpose (leaving the LV secondaries unconnected)?

The problem is insulation. Those two 110V primaries were probably simultaneously wound with two parallel strands of wire. If that incredibly thin layer of varnish on the wire punctures or burns through anywhere, the two windings are in electrical contact, and using it as an auto-transformer leaves you with no isolation between primary and secondary.

By contrast, the original factory-designed primary and secondary windings of that transformer will have a much heavier-duty secondary insulation barrier between them (usually the plastic bobbin the coils are wound on.)

So: if you need electrical isolation from the mains (and 99.99% of the time you do, the only exception is when you're feeding another properly isolated transformer from this one), don't do what you suggested.

-Gnobuddy

- Status

- Not open for further replies.

- Home

- Live Sound

- Instruments and Amps

- New Project with Wrong Power Transformer. WTD?