hi,

** sorry i had no choice, had t to make another thread for this. **

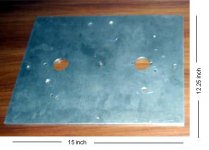

some one gave me two pcs aluminium plate, it is 6mm thick and L=15inch X W=12.25 inch. i am thinking to make this as a sink. anyone can give me any ideas how i can make nice heat sink with this plates? how many watts can be dissipate.

thank you for your kindness.

best regards

michael

** sorry i had no choice, had t to make another thread for this. **

some one gave me two pcs aluminium plate, it is 6mm thick and L=15inch X W=12.25 inch. i am thinking to make this as a sink. anyone can give me any ideas how i can make nice heat sink with this plates? how many watts can be dissipate.

thank you for your kindness.

best regards

michael

Attachments

good try, space2000

how many watts?

is not easy to know

you can only make some good estimation using some basic mathematic

and some practical measurements with some device mounted

can give a closer figure

DX Destroyer will know this better.

He has much practical experience. Of this.

I would ask him.

how many watts?

is not easy to know

you can only make some good estimation using some basic mathematic

and some practical measurements with some device mounted

can give a closer figure

DX Destroyer will know this better.

He has much practical experience. Of this.

I would ask him.

space 2000

you know very well that i dont like the way you procces things ...... but personaly i have nothing against you and no matter if i dont like it if possible i dlike to give you some help always in friendly tone .....

things you need to know :

not every piece of alouminioum is fit to be a heat sink IE there is material that look like aluminum but the material they are made of cannot transfer temperature very fast

one very cheap way to find out is to drill them with a HSS drill in quiet high rpm and then you notice that what comes out of the drill looks like a spring coil this is good aluminium .... if out of the drill is coming small triangle fragments of metal then your aluminium is crap and or not suitable for a heat sink

the reason that aluminium heatsinks are massive and includ NO bolts and screws in their construction is that EQUAL heat distribution is mandatory IE that the attachment of the "leaves" you ve made CANNOT guaranty that its possible to have EQUAL and then ENOUGH heat distribution and dissipation ....

to REpair this pice of aluminium is simply not cost effective you allready spend so much time in something that will not work ....

one more time you end up with something that looks like a heat sink or amplifier that might power up but will not perfom NOT 100% but not even 50% to my understanding ......

you need to change a few things in the way you think Its very nice to have everything hand made as long as it works .....also you sould read some book or look how others construct learn from it and then start to include any of your nice otherwise ideas of yours in the existing construction

friendly regards sakis

you know very well that i dont like the way you procces things ...... but personaly i have nothing against you and no matter if i dont like it if possible i dlike to give you some help always in friendly tone .....

things you need to know :

not every piece of alouminioum is fit to be a heat sink IE there is material that look like aluminum but the material they are made of cannot transfer temperature very fast

one very cheap way to find out is to drill them with a HSS drill in quiet high rpm and then you notice that what comes out of the drill looks like a spring coil this is good aluminium .... if out of the drill is coming small triangle fragments of metal then your aluminium is crap and or not suitable for a heat sink

the reason that aluminium heatsinks are massive and includ NO bolts and screws in their construction is that EQUAL heat distribution is mandatory IE that the attachment of the "leaves" you ve made CANNOT guaranty that its possible to have EQUAL and then ENOUGH heat distribution and dissipation ....

to REpair this pice of aluminium is simply not cost effective you allready spend so much time in something that will not work ....

one more time you end up with something that looks like a heat sink or amplifier that might power up but will not perfom NOT 100% but not even 50% to my understanding ......

you need to change a few things in the way you think Its very nice to have everything hand made as long as it works .....also you sould read some book or look how others construct learn from it and then start to include any of your nice otherwise ideas of yours in the existing construction

friendly regards sakis

sucessfully made heatsink-aleph-3 105w

oh..my god.....

i can't believe......just made my aleph-3 30watts to have 107wRMS. i placed all mosfets into this heat sink. ok, i tell you..i used 0.60 bias to make each pair to have 15wrms then i added total 14 mosfets so its become 7 pairs and it is now 105wRms class A.

Temp only now 50c+ , i havn't add any fan yet. after adding fan it will drop to 40c+ temp. its just nice...

i am testing now...for two hrs already.

oh..my god.....

i can't believe......just made my aleph-3 30watts to have 107wRMS. i placed all mosfets into this heat sink. ok, i tell you..i used 0.60 bias to make each pair to have 15wrms then i added total 14 mosfets so its become 7 pairs and it is now 105wRms class A.

Temp only now 50c+ , i havn't add any fan yet. after adding fan it will drop to 40c+ temp. its just nice...

i am testing now...for two hrs already.

hi sakis,

thanks for your comments. yes i already tested by dril. i found its spring coil comes out also can understand it is purly good alluminium.

as i am doing it at home so i can't make 100% really good heatsink. by righht its require lost of proper tools and i only have hammer, dril and cutter. as i am just hobbiest so made as much good as possible. its works well today just testing its performence. i used heat sink compounde under each fins. its really showing the sign of worm. thanks for your vlble info. it will help me more in future.

thanks for your comments. yes i already tested by dril. i found its spring coil comes out also can understand it is purly good alluminium.

as i am doing it at home so i can't make 100% really good heatsink. by righht its require lost of proper tools and i only have hammer, dril and cutter. as i am just hobbiest so made as much good as possible. its works well today just testing its performence. i used heat sink compounde under each fins. its really showing the sign of worm. thanks for your vlble info. it will help me more in future.

the use of cream

might save you ....but just a bit .....

in an application like that if one of the mosfets is in one area the doesnt get enough cooling or generaly less than the others this is the one mosfet that is going to kill your amp in the future or when the power demants too quickly

cause time is also related in a normal listenig situation when you built power slowly slowly then all is fine but if you demand power too quickly you might have a problem

when i was a kid i constructed a psu 0-30 volts for my bench simple stuff one lm 723 driving six very expensive transistors then the transistors were wired with 2.5 mm cable from collector to the reservoir cap ....since this was made lenght wise the first transistor was 5 cm away from the cap the secon 9 cm the third 12 cm and goes on

the power supply failed two or three times in ten years DO YOU KNOW WERE ?????

it failed in the transistor that had the longer cable ( no mater if the cable was 2.5 cm thick )

so replaced the various cables with a buss and supply all in the midle ......

hell i was using 6 2SA 1302 for this supply ( i had so many of them didnt know what to do with them so everything i constructed at the time was 1302-3281 )

also in amps like that thermal stability is a big or very big issue its not importand only to cool the amp down it is importand to keep the same temp to every transistor if possible

might save you ....but just a bit .....

in an application like that if one of the mosfets is in one area the doesnt get enough cooling or generaly less than the others this is the one mosfet that is going to kill your amp in the future or when the power demants too quickly

cause time is also related in a normal listenig situation when you built power slowly slowly then all is fine but if you demand power too quickly you might have a problem

when i was a kid i constructed a psu 0-30 volts for my bench simple stuff one lm 723 driving six very expensive transistors then the transistors were wired with 2.5 mm cable from collector to the reservoir cap ....since this was made lenght wise the first transistor was 5 cm away from the cap the secon 9 cm the third 12 cm and goes on

the power supply failed two or three times in ten years DO YOU KNOW WERE ?????

it failed in the transistor that had the longer cable ( no mater if the cable was 2.5 cm thick )

so replaced the various cables with a buss and supply all in the midle ......

hell i was using 6 2SA 1302 for this supply ( i had so many of them didnt know what to do with them so everything i constructed at the time was 1302-3281 )

also in amps like that thermal stability is a big or very big issue its not importand only to cool the amp down it is importand to keep the same temp to every transistor if possible

temp after 1hr run

hi,

now is morning 9+am. my amb temp is now 29c. i show you how my heatsink temp after one hr operate. you can see it is 47c and also the clock i use to check for an hr.

i am not professional in electronics. as it is, you seen some scratches but under the transistors are very nice shape no scratches at all...also i have touched each of the mosfets to check the temp, it is really nice and worm but not abnormal hot.

sorry i don't have scope. i just use my ear to listen the sound quality. offcourse there is more fine way to understand using scope....soon will have it...

thanks for comments. i valued all of your comments.

hi,

now is morning 9+am. my amb temp is now 29c. i show you how my heatsink temp after one hr operate. you can see it is 47c and also the clock i use to check for an hr.

i am not professional in electronics. as it is, you seen some scratches but under the transistors are very nice shape no scratches at all...also i have touched each of the mosfets to check the temp, it is really nice and worm but not abnormal hot.

sorry i don't have scope. i just use my ear to listen the sound quality. offcourse there is more fine way to understand using scope....soon will have it...

thanks for comments. i valued all of your comments.

Attachments

then you are

in the right track ......thats very good for starts .....when you get a scope you will see some other things also

in the right track ......thats very good for starts .....when you get a scope you will see some other things also

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Need ideas to make heat sink with this plate