Hi!

My good 'ol Paradigm PS1000 need a replacement, it cannot keep up with the lower frequenzies watching movies and music.

I got two barely used Cadence Beastmaster 12" subwoofers, BM122C, dual 2Ohm voicecoils.

Specs:

Z=1

Fs=32.5

Pe=1500

SPL=95.27

Re=0.8

Le=1.63

BL=11.99

Xmax=0.0063

Cms=0

Qms=8.1

Qes=0.37

Qts=0.35

Sd=0.048

Vas=23.9

Type=0

Link to spec: MODEL BM12-2C DVC 2-OHM SUBWOOFER 12 DRAG RACE BEASTMASTER - BEASTMASTER - Cadence Acoustics, LTD

Do anyone want to help me design one or two cabinets for these drivers that can create a stable volume down low,

OR

am I better of selling these drivers to get better suited ones. In that case, what drivers?

Also, I need suggestions on what amplifiers needed to power this subwoofer setup.

I am in the process of replacing my front speakers with horns, looking hard at the Lowther DX2 fullrange drivers, possibly going with a tube amp setup over time.

This sub need to match the new setup.

Due to lack of knowledge, I need to ask for help on this. How small can we make the cabinets and keep the puch down low?

After some reading, my current opinion is that a Folded tapped horn cabinet design should be it?

I hope someone have the time to help me out a little..

Thanks,

John

My good 'ol Paradigm PS1000 need a replacement, it cannot keep up with the lower frequenzies watching movies and music.

I got two barely used Cadence Beastmaster 12" subwoofers, BM122C, dual 2Ohm voicecoils.

Specs:

Z=1

Fs=32.5

Pe=1500

SPL=95.27

Re=0.8

Le=1.63

BL=11.99

Xmax=0.0063

Cms=0

Qms=8.1

Qes=0.37

Qts=0.35

Sd=0.048

Vas=23.9

Type=0

Link to spec: MODEL BM12-2C DVC 2-OHM SUBWOOFER 12 DRAG RACE BEASTMASTER - BEASTMASTER - Cadence Acoustics, LTD

Do anyone want to help me design one or two cabinets for these drivers that can create a stable volume down low,

OR

am I better of selling these drivers to get better suited ones. In that case, what drivers?

Also, I need suggestions on what amplifiers needed to power this subwoofer setup.

I am in the process of replacing my front speakers with horns, looking hard at the Lowther DX2 fullrange drivers, possibly going with a tube amp setup over time.

This sub need to match the new setup.

Due to lack of knowledge, I need to ask for help on this. How small can we make the cabinets and keep the puch down low?

After some reading, my current opinion is that a Folded tapped horn cabinet design should be it?

I hope someone have the time to help me out a little..

Thanks,

John

Hi again.

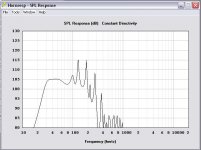

Tried out the Hornresp program, entered the info on the drivers. I didn't get the flat spl response other people do on their projects. I'm not able to alter the enclosure data to fix the peaky SPL response when simulating a tapped folded horn.. More reading is required!

I'll come up with the data used when I get home to my computer..

Tried out the Hornresp program, entered the info on the drivers. I didn't get the flat spl response other people do on their projects. I'm not able to alter the enclosure data to fix the peaky SPL response when simulating a tapped folded horn.. More reading is required!

An externally hosted image should be here but it was not working when we last tested it.

I'll come up with the data used when I get home to my computer..

Hi!

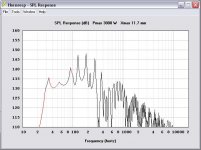

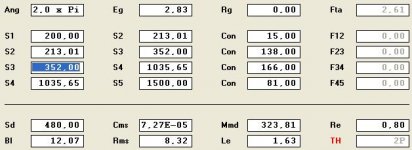

The picture from my previous post was moved. Here it is:

I have been reading a little, tried different stuff in Hornresp to get my drivers to respond differently to simulated enclosures, without too much luck, because my lack of knowledge.

Tonight I tried a known enclosure, I found the The Eminence TH from the Tapped Horns site to see how one of my drivers simulate in that one with my parametres for the driver.

Look what happened! The lower corner dropped to 20Hz! Atleast I got a change in the SPL response..

The lower corner dropped to 20Hz! Atleast I got a change in the SPL response..

But there is a 15Db drop from 20Hz to 28Hz, I want a more smooth response than that? What can I do to smooth things out a little?

Is it a good idea to try to fold this horn to save some space(WAF improvement)?

Do I need two drivers? Will I benefit from two when watching movies and listening to music, or is it overkill for a set of Lowther DX2 loaded horns?

If I want to decrease the size, where is a good place to start, I want to keep the low corner close to 20Hz. The upper corner doesn't have to be more than 70Hz if I get the good fullrange Horn fronts I want.

The picture from my previous post was moved. Here it is:

I have been reading a little, tried different stuff in Hornresp to get my drivers to respond differently to simulated enclosures, without too much luck, because my lack of knowledge.

Tonight I tried a known enclosure, I found the The Eminence TH from the Tapped Horns site to see how one of my drivers simulate in that one with my parametres for the driver.

Look what happened!

But there is a 15Db drop from 20Hz to 28Hz, I want a more smooth response than that? What can I do to smooth things out a little?

Is it a good idea to try to fold this horn to save some space(WAF improvement)?

Do I need two drivers? Will I benefit from two when watching movies and listening to music, or is it overkill for a set of Lowther DX2 loaded horns?

If I want to decrease the size, where is a good place to start, I want to keep the low corner close to 20Hz. The upper corner doesn't have to be more than 70Hz if I get the good fullrange Horn fronts I want.

Last edited:

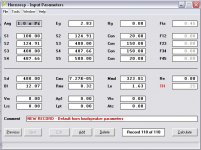

You're still not simulating a tapped horn, but you're close.

See the Nd on your input screen? That box should say TH for a tapped horn simulation.

Here's a little writeup I did:

Tapped Horn Tutorial

It is by no means complete, but it will get you started.

See the Nd on your input screen? That box should say TH for a tapped horn simulation.

Here's a little writeup I did:

Tapped Horn Tutorial

It is by no means complete, but it will get you started.

You're still not simulating a tapped horn, but you're close.

See the Nd on your input screen? That box should say TH for a tapped horn simulation.

Here's a little writeup I did:

Tapped Horn Tutorial

It is by no means complete, but it will get you started.

Thanks for the tip!

Amplifier:

I have been a little worried about powering these babies inside a house.. But any conserns about power just went out the window! The price is good too!

Someone gave me the link to this amplifier, THE T.AMP PROLINE 3000, 2x 1500W @ 4 Ohms, 2x 1100W @ 8 Ohms, 2x 1800W @ 2 Ohms.. Weight 37kgs.

If I decide to run only one of the two Beastmasters, it can run 1800W into each coil @ 2ohms. Better WAF with only one driver..

My first concern is sound quality on a PA amp like this? Anyone with experience? Will the sound quality be good enough for a subwoofer setup?

Will it fit a setup with the Lowther DX2's and Acousta 116 cabinet like my plan is to do before summer?

I don't want rumbling ugly loud bass at all times. Accurate and precise bass into the ground is the target, but want the overall SPL response to be somewhat linear.

Any advice appreciated..

John

Thanks!

Hmm.. I live in a concrete house with 8" reinforced walls.. Was not planning on reinforce it further!

Is it possible to tune this thing lower? I can see it drop from 30Hz down, where the fun begin when watching movies!

Or will a lower window make that much bigger of a box and kill any WAF, if there is any from the start?

Thanks for your help.

John

Hmm.. I live in a concrete house with 8" reinforced walls.. Was not planning on reinforce it further!

Is it possible to tune this thing lower? I can see it drop from 30Hz down, where the fun begin when watching movies!

Or will a lower window make that much bigger of a box and kill any WAF, if there is any from the start?

Thanks for your help.

John

These woofers should be able to play a bit lower - one of the rules of thumb with a tapped horn is that you can design them for response that is lower than the drivers Fs. With the right drivers, you can get response to 1/2 the Fs.

Unfortunately, these aren't really the right drivers in that regard. With this particular driver in a simple conic taper, once you lengthen the horn to get to 20 Hz, the passband response starts to get a bit too lumpy unless S2 is set rather small (high compression ratio).

Hoffman's Iron Law applies though - as the response gets lower, cabinets get bigger or efficiency drops. No free lunches here

Unfortunately, these aren't really the right drivers in that regard. With this particular driver in a simple conic taper, once you lengthen the horn to get to 20 Hz, the passband response starts to get a bit too lumpy unless S2 is set rather small (high compression ratio).

Hoffman's Iron Law applies though - as the response gets lower, cabinets get bigger or efficiency drops. No free lunches here

Hmm.. To keep things smaller, I'm considering only one driver, keeping the other as a spare if something bad happens.These woofers should be able to play a bit lower - one of the rules of thumb with a tapped horn is that you can design them for response that is lower than the drivers Fs. With the right drivers, you can get response to 1/2 the Fs.

Unfortunately, these aren't really the right drivers in that regard. With this particular driver in a simple conic taper, once you lengthen the horn to get to 20 Hz, the passband response starts to get a bit too lumpy unless S2 is set rather small (high compression ratio).

Hoffman's Iron Law applies though - as the response gets lower, cabinets get bigger or efficiency drops. No free lunches here

What is the "best" cabinet size and lengths from your point of view?

How much can be done with stuffing?

Can I expect some kind of quality bass from it? These drivers are incredibly hard or got a stiff suspension compared to other drivers I've played with. But they sound very accurate. Mabye a sealed box is better?

1001 questions, but it's easier to modify the design now than later.

Thnxx

In all honesty, with respect to tapped horns, though I am a ways down the path, I do not feel that I am not that far off the vertical part of the learning curve. As I figure out some things, I learn of dozens more that I need to learn about.

They are not a bad driver, they are just not a truly optimal driver for use in a tapped horn (honestly - I think the truly optimal tapped horn drivers could be counted on one hand....). It is my understanding that that series is designed for car SPL competition, so they probably like small sealed or ported cabinets, tuned relatively high to take advantage of cabin gain. A 25 Hz. tapped horn for this driver is actually a fairly small cabinet, you'll probably have a hard time fitting the driver into it. It appears that 25 Hz is within reach without getting too esoteric. Keep S2 to no less than Sd/4 and you should be OK. Make L12 as short as possible (1/2 the driver diameter) to keep the impulse response accurate. Adjust things slightly to get the phase right, and you're set for sawdust.

Don't worry too much about the ripples in the modeled passband response if they are less than 3 dB. My experience has indicated that they will be there, but 3 dB is not that big a deal. Room issues will likely be much bigger. As it is a horn, stuffing is a bad idea. Batting stapled to the walls has been shown to help, but it is truly a try it and see approach as each build is different. I'd suggest that you concentrate on the throat and the area near the driver on the mouth side first.

Though they can be simply described, these actually are pretty complicated cabinets. Bracing is a must. Good cabinet material is a must. Accurate layout and construction is a must. Cutting corners and using cheap materials will lead to problems. Long designs (single-fold) may experience cancellation issues. Additionally, more folds attenuate the high frequencies, within reason.

The box I just built as a test (though fairly well-braced) had visible resonances in the access panel with only 10 watts applied. Admittedly, I used cheap 1/2" plywood and 1/2" MDF, it was never designed as anything other than a proof of concept so that I could get some more measurements and try a few more things out.

Imagine what a kilowatt would do to a cabinet like this. There is a reason Danley uses 3/4" birch plywood.

Tapped horns can be accurate, and can be musical, you just have to design and build them right. It is all in the design and implementation, the devil truly is in the details.

Mr. Danley said something like this first, but I can't repeat it enough:

Measure what you plan to model (measure the actual Thiele-Small parameters for your drivers)

Model what you've measured (get the data into Hornresp accurately)

Build what you've modeled (translate the areas and taper rates into an enclosure accurately)

and you'll actually measure pretty close to what you predicted.

If not - it is not the model's fault.

The only time I did not get reasonably close to the predicted result was due to a building error on my part.

They are not a bad driver, they are just not a truly optimal driver for use in a tapped horn (honestly - I think the truly optimal tapped horn drivers could be counted on one hand....). It is my understanding that that series is designed for car SPL competition, so they probably like small sealed or ported cabinets, tuned relatively high to take advantage of cabin gain. A 25 Hz. tapped horn for this driver is actually a fairly small cabinet, you'll probably have a hard time fitting the driver into it. It appears that 25 Hz is within reach without getting too esoteric. Keep S2 to no less than Sd/4 and you should be OK. Make L12 as short as possible (1/2 the driver diameter) to keep the impulse response accurate. Adjust things slightly to get the phase right, and you're set for sawdust.

Don't worry too much about the ripples in the modeled passband response if they are less than 3 dB. My experience has indicated that they will be there, but 3 dB is not that big a deal. Room issues will likely be much bigger. As it is a horn, stuffing is a bad idea. Batting stapled to the walls has been shown to help, but it is truly a try it and see approach as each build is different. I'd suggest that you concentrate on the throat and the area near the driver on the mouth side first.

Though they can be simply described, these actually are pretty complicated cabinets. Bracing is a must. Good cabinet material is a must. Accurate layout and construction is a must. Cutting corners and using cheap materials will lead to problems. Long designs (single-fold) may experience cancellation issues. Additionally, more folds attenuate the high frequencies, within reason.

The box I just built as a test (though fairly well-braced) had visible resonances in the access panel with only 10 watts applied. Admittedly, I used cheap 1/2" plywood and 1/2" MDF, it was never designed as anything other than a proof of concept so that I could get some more measurements and try a few more things out.

Imagine what a kilowatt would do to a cabinet like this. There is a reason Danley uses 3/4" birch plywood.

Tapped horns can be accurate, and can be musical, you just have to design and build them right. It is all in the design and implementation, the devil truly is in the details.

Mr. Danley said something like this first, but I can't repeat it enough:

Measure what you plan to model (measure the actual Thiele-Small parameters for your drivers)

Model what you've measured (get the data into Hornresp accurately)

Build what you've modeled (translate the areas and taper rates into an enclosure accurately)

and you'll actually measure pretty close to what you predicted.

If not - it is not the model's fault.

The only time I did not get reasonably close to the predicted result was due to a building error on my part.

Last edited:

...As I figure out some things, I learn of dozens more that I need to learn about...

I'm the guy looking at the moon, thinking, it would sure have been a nice experince to go there, but it's soo far.. Really feel what you are saying here, learn one thing and need to learn several other things to go forward.

They are not a bad driver, they are just not a truly optimal driver for use in a tapped horn (honestly - I think the truly optimal tapped horn drivers could be counted on one hand....). It is my understanding that that series is designed for car SPL competition, so they probably like small sealed or ported cabinets, tuned relatively high to take advantage of cabin gain.

Yes, they are. Never intended for a TH. Just hope their rigid suspension will prevent over-excursion and prove stable in a setup like this. Also being built for DB-drag's, hopefully they will handle som beating.

A 25 Hz. tapped horn for this driver is actually a fairly small cabinet, you'll probably have a hard time fitting the driver into it. It appears that 25 Hz is within reach without getting too esoteric. Keep S2 to no less than Sd/4 and you should be OK. Make L12 as short as possible (1/2 the driver diameter) to keep the impulse response accurate. Adjust things slightly to get the phase right, and you're set for sawdust

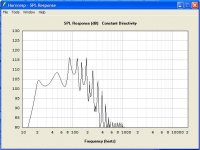

Don't worry too much about the ripples in the modeled passband response if they are less than 3 dB. My experience has indicated that they will be there, but 3 dB is not that big a deal.

I made a new model just now, looks a little better, but about 6db is a little much?

..Batting stapled to the walls has been shown to help, but it is truly a try it and see approach as each build is different. I'd suggest that you concentrate on the throat and the area near the driver on the mouth side first...

That was what I meant..

Though they can be simply described, these actually are pretty complicated cabinets. Bracing is a must. Good cabinet material is a must. Accurate layout and construction is a must. Cutting corners and using cheap materials will lead to problems. Long designs (single-fold) may experience cancellation issues. Additionally, more folds attenuate the high frequencies, within reason.

I'm probably way over my head at this moment, but who wants, need to do.

I found this very informative site about tapped horns and folding a tapped horn.

The box I just built as a test (though fairly well-braced) had visible resonances in the access panel with only 10 watts applied. Admittedly, I used cheap 1/2" plywood and 1/2" MDF, it was never designed as anything other than a proof of concept so that I could get some more measurements and try a few more things out.

Imagine what a kilowatt would do to a cabinet like this. There is a reason Danley uses 3/4" birch plywood.[/QUOTE]

My plan is to use something like 30mm MDF and bracing. This thing needs to be rock stable.

Measure what you plan to model (measure the actual Thiele-Small parameters for your drivers)

Fysical measure them? How?

Thanks.

Attachments

If you haven't guessed, I am a BIG proponent of measuring things. Ohms are data. Decibels are data. Volts and amps are data. Flowery descriptions of the "fullness" of the sound, or the "depth" and "impact" of the bass aren't data.

Yeah, I'm a scientist at my day job.

I measure my own drivers with my laptop computer and Smith & Larson's Woofer Tester 2. For complicated enclosure designs, this is one way to take some of the variables out, as well as measure what you built so you can figure out if you got it right or help determine what might have gone wrong.

They are not cheap. They take some time to complete measurements, and they are extremely accurate. This is not the WT3 sold by Parts Express.

There are other ways to do this - Praxis, ARTA, and Speaker Workshop come to mind. Some of these are free. Since I have used the Woofer Tester and Woofer Tester 2 for years, I never bothered really researching these options.

These devices and programs also measure impedance, which is key in understanding the performance of a driver in an enclosure. If the impedance is not what the model predicted, something is wrong. It only takes a few minutes to do a detailed impedance sweep, and that can tell me volumes about what I have built. It takes me longer to make pretty graphs of my results.

Sealed or ported boxes? Use the manufacturer specs or recommendations. Drivers destined for more complicated enclosures really should be measured first. If you go through the effort to design and build a complicated enclosure without measuring what you're working with, the chances of frustration with the results are much higher. When things go wrong in complicated enclosures, they go really wrong.

The mountain at 50 and the valley at 70 will be a problem. Many rooms have a notch at 70 already, having a 6 dB dip due to design there is not a good idea. Don't get so hung up on getting that last 5 Hz either. 30 Hz done really well will usually sound a lot better than 20 Hz done poorly.

Hornresp also tells you a lot of other information with the other charts. Be sure to look at phase, electrical impedance, and excursion. Not just the absolute values on the charts, but the shapes of the plot.

Yeah, I'm a scientist at my day job.

I measure my own drivers with my laptop computer and Smith & Larson's Woofer Tester 2. For complicated enclosure designs, this is one way to take some of the variables out, as well as measure what you built so you can figure out if you got it right or help determine what might have gone wrong.

They are not cheap. They take some time to complete measurements, and they are extremely accurate. This is not the WT3 sold by Parts Express.

There are other ways to do this - Praxis, ARTA, and Speaker Workshop come to mind. Some of these are free. Since I have used the Woofer Tester and Woofer Tester 2 for years, I never bothered really researching these options.

These devices and programs also measure impedance, which is key in understanding the performance of a driver in an enclosure. If the impedance is not what the model predicted, something is wrong. It only takes a few minutes to do a detailed impedance sweep, and that can tell me volumes about what I have built. It takes me longer to make pretty graphs of my results.

Sealed or ported boxes? Use the manufacturer specs or recommendations. Drivers destined for more complicated enclosures really should be measured first. If you go through the effort to design and build a complicated enclosure without measuring what you're working with, the chances of frustration with the results are much higher. When things go wrong in complicated enclosures, they go really wrong.

The mountain at 50 and the valley at 70 will be a problem. Many rooms have a notch at 70 already, having a 6 dB dip due to design there is not a good idea. Don't get so hung up on getting that last 5 Hz either. 30 Hz done really well will usually sound a lot better than 20 Hz done poorly.

Hornresp also tells you a lot of other information with the other charts. Be sure to look at phase, electrical impedance, and excursion. Not just the absolute values on the charts, but the shapes of the plot.

Thanks alot on the info!

I'm actually considering to get the Woofer Tester 2 now, the price is not outrageous, and I might use it to check my future front speakers as well?

Easy to use?

I'm working with 0,01mm tolerances daily, and measuring is a part of my profession, so I'm hopeless about being too accurate..

I'm going to aim for your advice of approximately 25Hz and see how things will get. Also try to even out the 50Hz mountain. Hopefully I can put my x-over at approx 60Hz with my coming new front speakers.

When it comes to phase, electrical impedance, and excursion, what am I to look for?

Thanks alot,

John

I'm actually considering to get the Woofer Tester 2 now, the price is not outrageous, and I might use it to check my future front speakers as well?

Easy to use?

I'm working with 0,01mm tolerances daily, and measuring is a part of my profession, so I'm hopeless about being too accurate..

I'm going to aim for your advice of approximately 25Hz and see how things will get. Also try to even out the 50Hz mountain. Hopefully I can put my x-over at approx 60Hz with my coming new front speakers.

When it comes to phase, electrical impedance, and excursion, what am I to look for?

Thanks alot,

John

honestly - I think the truly optimal tapped horn drivers could be counted on one hand....

Would you be so kind and count them for me? I allways thought one could find a TH for allmost every driver, but maybe some good ones just slipped through my hands.

Would you be so kind and count them for me? I allways thought one could find a TH for allmost every driver, but maybe some good ones just slipped through my hands.

Just like any other type of speaker cabinet, you can make almost anything work, but very, very, few work well. The devil is in the details, and frequency response is only one part of the picture. Just as any driver can be placed into a ported box, some drivers work better. Same goes for sealed, bandpass, horns, tapped horns, or any other type of enclosure.

I have not figured all of this out yet, believe me. So far, I'm finding that truly optimal drivers for a tapped horn are pretty rare. There are a lot smarter folks out there than me, and I would not have learned what I know without them.

I have found that in some simulations with certain drivers, in certain horns, the driver's excursion does not explode below horn cutoff, creating a very characteristic shape in the lowest hump of the simulated driver's excursion curve. This is an optimal driver in a proper tapped horn.

As I do not own any drivers that exhibit this behavior in simulations (yet - but some are already ordered), I have not confirmed this behavior firsthand - so take it all with a grain of salt for now. Hornresp and Akabak do not lie. Give the program good data and it will approximate the actual performance. I will provide more information once I have measured and tested a driver that behaves this way in simulations.

Things I look for in choosing a driver for a tapped horn:

High BL (over 12)

High Fs (2X low corner)

Very Low Vas (depends on driver size)

Very High Xmax

Extremely High Xmech

Very High BL^2/Re

You will find that this is actually a pretty short list. I have not looked at every driver on the planet, but I have certainly looked at a bunch. Currently, outside of the drivers known or suspected to be used in the Danley products, I have found 4 or 5 drivers that I would recommend (or purchase for myself, and I have already ordered one on that list).

Thanks alot on the info!

I'm actually considering to get the Woofer Tester 2 now, the price is not outrageous, and I might use it to check my future front speakers as well?

Easy to use?

I'm working with 0,01mm tolerances daily, and measuring is a part of my profession, so I'm hopeless about being too accurate..

I'm going to aim for your advice of approximately 25Hz and see how things will get. Also try to even out the 50Hz mountain. Hopefully I can put my x-over at approx 60Hz with my coming new front speakers.

When it comes to phase, electrical impedance, and excursion, what am I to look for?

Thanks alot,

John

I don't think it is too hard to use, and for the data it provides, it is actually a bargain. I measure all my drivers with it - helps with crossover design as well as proper enclosure design or verification. Also helps a bunch with final tuning of enclosures.

I've shared most of what I know here, some of the smarter kids have chimed in in other threads (the collaborative thread here, some over at AVS). I know it is a needle in a haystack sort of thing - believe me - I am digging for that needle too.

As MaVo correctly stated - you can make a tapped horn for nearly any driver out there. Done right - it will sound great. I know - I have made several.

All I was trying to point out is that a truly optimal tapped horn (something like Danley sells) requires drivers with a somewhat odd set of specifications, but they appear to yield a behavior that is significantly different than that of the vast majority of drivers out there.

Remember, like I said earlier, I am still learning, and the learning curve is still very steep.

Last edited:

Things I look for in choosing a driver for a tapped horn:

High BL (over 12)

High Fs (2X low corner)

Very Low Vas (depends on driver size)

Very High Xmax

Extremely High Xmech

Very High BL^2/Re

High BL (over 12): Doesnt say much without knowing Re, but you added the correct BL^2/Re, so one could cut this one out.

High Fs (2X low corner): This doesnt exclude any drivers from the list, it only hints on what is the optimal horn for a given driver. However, high fs is unusual in hifi subwoofers, so one is left with car audio and pro stuff for usable low corners.

Very High Xmax: Depends on how effective per volume the box should be. But the fact that more excursion is better applies to all drivers and designs.

Extremely High Xmech: Same as above.

Very High BL^2/Re: This is a more tricky one. I think a high value is good for flatter frequency response in TH's, but usually one can find a way to get at least one flat response.

The thing you mention with the drivers excursion not rising higher in the really low frequencies is an effect of a hard suspension and not really an indicator of how well it fits into the TH application. Even with a TH, every driver has the same max output per area * excursion.

What i want to say is, except the rather unclear but promising value BL^2/Re, the points you listed do not really apply here due to various reasons. I would really be interesed in knowing more about what makes a driver good for a tapped horn and i also was at this stage in my thought process once, but right now, it looks like alot of drivers will do.

so share the wealth

what are the best drivers for tapped horns?? and why?/

what are the best drivers for tapped horns?? and why?/

In all honesty, with respect to tapped horns, though I am a ways down the path, I do not feel that I am not that far off the vertical part of the learning curve. As I figure out some things, I learn of dozens more that I need to learn about.

They are not a bad driver, they are just not a truly optimal driver for use in a tapped horn (honestly - I think the truly optimal tapped horn drivers could be counted on one hand....). It is my understanding that that series is designed for car SPL competition, so they probably like small sealed or ported cabinets, tuned relatively high to take advantage of cabin gain. A 25 Hz. tapped horn for this driver is actually a fairly small cabinet, you'll probably have a hard time fitting the driver into it. It appears that 25 Hz is within reach without getting too esoteric. Keep S2 to no less than Sd/4 and you should be OK. Make L12 as short as possible (1/2 the driver diameter) to keep the impulse response accurate. Adjust things slightly to get the phase right, and you're set for sawdust.

Don't worry too much about the ripples in the modeled passband response if they are less than 3 dB. My experience has indicated that they will be there, but 3 dB is not that big a deal. Room issues will likely be much bigger. As it is a horn, stuffing is a bad idea. Batting stapled to the walls has been shown to help, but it is truly a try it and see approach as each build is different. I'd suggest that you concentrate on the throat and the area near the driver on the mouth side first.

Though they can be simply described, these actually are pretty complicated cabinets. Bracing is a must. Good cabinet material is a must. Accurate layout and construction is a must. Cutting corners and using cheap materials will lead to problems. Long designs (single-fold) may experience cancellation issues. Additionally, more folds attenuate the high frequencies, within reason.

The box I just built as a test (though fairly well-braced) had visible resonances in the access panel with only 10 watts applied. Admittedly, I used cheap 1/2" plywood and 1/2" MDF, it was never designed as anything other than a proof of concept so that I could get some more measurements and try a few more things out.

Imagine what a kilowatt would do to a cabinet like this. There is a reason Danley uses 3/4" birch plywood.

Tapped horns can be accurate, and can be musical, you just have to design and build them right. It is all in the design and implementation, the devil truly is in the details.

Mr. Danley said something like this first, but I can't repeat it enough:

Measure what you plan to model (measure the actual Thiele-Small parameters for your drivers)

Model what you've measured (get the data into Hornresp accurately)

Build what you've modeled (translate the areas and taper rates into an enclosure accurately)

and you'll actually measure pretty close to what you predicted.

If not - it is not the model's fault.

The only time I did not get reasonably close to the predicted result was due to a building error on my part.

Look up.

I laid out what I look for in post 16. My criteria may not be the same as yours. I don't do pro-sound, I do home music and home theater. I don't run wide open at the ragged edge all night long (well, not that often anyways....).

Like MaVo stated, nearly any driver can have a tapped horn modeled around it. Similarly, nearly any driver can have a sealed or ported enclosure modeled around it. Your criteria (and your ears) will tell you what's best.

If you can find a high-excursion driver with a low Vas and a relatively high Fs, as well as a very high BL, you might have a good candidate for use in a tapped horn.

Truly, the only way to know is to measure, model, build, then measure.

I laid out what I look for in post 16. My criteria may not be the same as yours. I don't do pro-sound, I do home music and home theater. I don't run wide open at the ragged edge all night long (well, not that often anyways....).

Like MaVo stated, nearly any driver can have a tapped horn modeled around it. Similarly, nearly any driver can have a sealed or ported enclosure modeled around it. Your criteria (and your ears) will tell you what's best.

If you can find a high-excursion driver with a low Vas and a relatively high Fs, as well as a very high BL, you might have a good candidate for use in a tapped horn.

Truly, the only way to know is to measure, model, build, then measure.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Need help, designing TH sub with 2x12" drivers.