hardwood

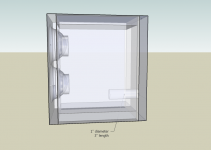

As I posted above, I was originally planning on using 3/4" plywood for the enclosures, but realized that I have suitable hardwood planks that I could easily cut for the panels. The dimensions of the finished design lend themselves to use of US-market dimensional lumber. Rather than being lazy, I'm attempting to use as many good "factory" edges as I can. I don't have a table saw and although I've made some furniture cabinets using a straight-edge and my low-end circular saw, blade deflection, cheap tools, and inexperience led to somewhat wavy cuts. The front and rear baffles would be made from 3/4" Paduak ("Puh-dook" in the local parlance) and the remaining panels from 3/4" rock maple. From what I gather reading other threads, hardwood seems to be a controversial building material from both sonic and mechanical stability perspectives. If I use these materials I'll be applying 3 coats of lacquer to both the interior and exterior surfaces to limit moisture-related expansion and contraction (and hopefully cracking). All glue-joint surfaces will be masked before I apply the lacquer. Any other advice?

As I posted above, I was originally planning on using 3/4" plywood for the enclosures, but realized that I have suitable hardwood planks that I could easily cut for the panels. The dimensions of the finished design lend themselves to use of US-market dimensional lumber. Rather than being lazy, I'm attempting to use as many good "factory" edges as I can. I don't have a table saw and although I've made some furniture cabinets using a straight-edge and my low-end circular saw, blade deflection, cheap tools, and inexperience led to somewhat wavy cuts. The front and rear baffles would be made from 3/4" Paduak ("Puh-dook" in the local parlance) and the remaining panels from 3/4" rock maple. From what I gather reading other threads, hardwood seems to be a controversial building material from both sonic and mechanical stability perspectives. If I use these materials I'll be applying 3 coats of lacquer to both the interior and exterior surfaces to limit moisture-related expansion and contraction (and hopefully cracking). All glue-joint surfaces will be masked before I apply the lacquer. Any other advice?

Perhaps you can research the use of cement-board to line the interior of the cabinet. I am considering this myself for my Aura build. I've read that cement-board strategically affixed to the interior walls would absorb some of the cabinet vibrations, which can supposedly be an issue when using hardwoods. There is also an aerosol spray dampening material mentioned in some of the recent threads, not sure what the brand name is called though nor it's actual composition but i figured i'd throw some ideas out there...

Your thread originally caught my eye since i had also purchased some of the PE Aura drivers to get my feet wet in speaker building, the fullrange type to be more specific. Haven't decided upon the cabinet design but i will use some of this nice rustic looking red cedar. I notice there's decent imaging, treble and vocal clarity with these aura drivers (or clones, whatever they are). My test pair are using helper tweeters crossed with 2.2uf capacitors, crossing these mylar dome tweeters lower seems to interfere and doesn't sound as good imho. I've tested this makeshift pair with a sonic T-amp, a JVC hybrid-digital reciever and this radioshack solid-state amp. The radioshack amp actually sounds pretty good and it's still available at many stores btw, type in your zip code here to check local availability, makes a good workbench test-amp imho, more info about it here.

Wish you luck with the rest of your project OP, am curious to see how it turns out and to hear your impressions 🙂

Your thread originally caught my eye since i had also purchased some of the PE Aura drivers to get my feet wet in speaker building, the fullrange type to be more specific. Haven't decided upon the cabinet design but i will use some of this nice rustic looking red cedar. I notice there's decent imaging, treble and vocal clarity with these aura drivers (or clones, whatever they are). My test pair are using helper tweeters crossed with 2.2uf capacitors, crossing these mylar dome tweeters lower seems to interfere and doesn't sound as good imho. I've tested this makeshift pair with a sonic T-amp, a JVC hybrid-digital reciever and this radioshack solid-state amp. The radioshack amp actually sounds pretty good and it's still available at many stores btw, type in your zip code here to check local availability, makes a good workbench test-amp imho, more info about it here.

Wish you luck with the rest of your project OP, am curious to see how it turns out and to hear your impressions 🙂

Same good luck to you, sjetski71! Please post some info on your final design(s). I lurked around this forum for quite some time before diving in, and always looked forward to seeing what other people were doing with the less expensive drivers.

I believe I read a thread a couple of weeks ago about using "dip-it"(?) to treat cabinets. Dip-it is a rubber-like compound used to coat tool handles. I've some experience coating machete handles and such and suspect it might do some good. It has been a few years since I purchased it, so I'll have to check on the costs to see if it's worth it. With the relatively narrow enclosures I'm building, it would be much better to take care of any surface treatments before everything in crammed in...

Squib

I believe I read a thread a couple of weeks ago about using "dip-it"(?) to treat cabinets. Dip-it is a rubber-like compound used to coat tool handles. I've some experience coating machete handles and such and suspect it might do some good. It has been a few years since I purchased it, so I'll have to check on the costs to see if it's worth it. With the relatively narrow enclosures I'm building, it would be much better to take care of any surface treatments before everything in crammed in...

Squib

found it in a spray can

Plasti-dip is the name of the product. I guess it now comes in a spray can as well as can (or bucket if your building BIB's or BLH's😉. Cheap enough I might give it a shot.

Link to one online dealer: http://garage-toys.com/plspbl.html

Plasti-dip is the name of the product. I guess it now comes in a spray can as well as can (or bucket if your building BIB's or BLH's😉. Cheap enough I might give it a shot.

Link to one online dealer: http://garage-toys.com/plspbl.html

newflash from the kiddie pool...

It is awfully hard to freehand-cut a 3" diameter hole with a jigsaw . If anyone needs any other brilliant woodworking insights, please don't hesitate to ask. I'm available seven days a week.

. If anyone needs any other brilliant woodworking insights, please don't hesitate to ask. I'm available seven days a week.

It is awfully hard to freehand-cut a 3" diameter hole with a jigsaw

. If anyone needs any other brilliant woodworking insights, please don't hesitate to ask. I'm available seven days a week.

. If anyone needs any other brilliant woodworking insights, please don't hesitate to ask. I'm available seven days a week.1st box

This shot "artfully" obscures my 8th grade shop-class level woodwork. The Paduak is beautiful, but quite orange in color. It will darken significantly over time and look more like rosewood. Please ignore my sloppiness with the glue...everything will be sanded again once the panels are fully glued.

On a side note, I somehow neglected to foresee how far recessed the drivers will be when mounted to the rear of the front baffle. I know, it's 3/4", but 3/4" looks a lot deeper than I imagined. They look like shallow horn loaded mid-range speakers. Given the irregularities in the contours of the baffle (done with a rasp and dremel) I think I might be on my way to the world's first "Stochastic Horn Loaded 0.5 way PC Speaker".

This shot "artfully" obscures my 8th grade shop-class level woodwork. The Paduak is beautiful, but quite orange in color. It will darken significantly over time and look more like rosewood. Please ignore my sloppiness with the glue...everything will be sanded again once the panels are fully glued.

On a side note, I somehow neglected to foresee how far recessed the drivers will be when mounted to the rear of the front baffle. I know, it's 3/4", but 3/4" looks a lot deeper than I imagined. They look like shallow horn loaded mid-range speakers. Given the irregularities in the contours of the baffle (done with a rasp and dremel) I think I might be on my way to the world's first "Stochastic Horn Loaded 0.5 way PC Speaker".

Attachments

A little off topic but im just wondering what you use to do speaker modelling.

Can i enter response curves into this program and related information to get a better idea of the finished speaker. Im new to all this have only ever used kits.

thanks

Can i enter response curves into this program and related information to get a better idea of the finished speaker. Im new to all this have only ever used kits.

thanks

I myself am very new to this (see above). Reading threads on this forum and other web sites led me to WinSID (free download) for basic modeling. WinSID has a small library of drivers in its internal database, but others can be added easily. Unibox is another easy to use program that can get you headed in the right direction. I'd recommend you use the search function on this site, it will save you time and heartache... Oh, and don't take advice from me . A little reading on this site should give you a pretty good idea of who to rely on for sound and sage guidance. Good luck.

. A little reading on this site should give you a pretty good idea of who to rely on for sound and sage guidance. Good luck.

. A little reading on this site should give you a pretty good idea of who to rely on for sound and sage guidance. Good luck.

. A little reading on this site should give you a pretty good idea of who to rely on for sound and sage guidance. Good luck.damping

I've been reading other threads on vented cabinet damping. I was planning on using urethane foam sheets to line the rear and bottom panels. From what I gather, many folks believe (know?) this material works very poorly, but zaph suggests it's suitable for low-cost projects. The stuff I have on hand is packaged for use as chair pads. It's a medium density foam cut to 16"x16"x1" sheets. 1" thickness seems a bit much in such a small enclosure, and I'm concerned about the loss in net volume. I bumped the height of the cabinets up another 1/2" to 10" to compensate for the driver and port volume, as the WinSID modeling suggested slightly larger volumes would be more "forgiving".Would cutting the foam material down to 3/4" or even 1/2" be a good starting point for experimentation? I did end up purchasing a small can of plasti-dip that I will use to coat the interior surfaces of the panels before applying any foam. I just need to get a small amount of naphtha to thin the coating before brushing it on. I was unable to find a local source for the aerosol can variety.

All of this is taking far longer than I imagined when I started day-dreaming about the project, but I'm trying to avoid any MORE rookie mistakes. My choices to re-style a proven design (Timn8ter's PC speakers), switch to a 0.5 way design, AND use hardwood panels have introduced a lot of uncertainty in the final results. Thanks again to those of you kind enough to help!

I've been reading other threads on vented cabinet damping. I was planning on using urethane foam sheets to line the rear and bottom panels. From what I gather, many folks believe (know?) this material works very poorly, but zaph suggests it's suitable for low-cost projects. The stuff I have on hand is packaged for use as chair pads. It's a medium density foam cut to 16"x16"x1" sheets. 1" thickness seems a bit much in such a small enclosure, and I'm concerned about the loss in net volume. I bumped the height of the cabinets up another 1/2" to 10" to compensate for the driver and port volume, as the WinSID modeling suggested slightly larger volumes would be more "forgiving".Would cutting the foam material down to 3/4" or even 1/2" be a good starting point for experimentation? I did end up purchasing a small can of plasti-dip that I will use to coat the interior surfaces of the panels before applying any foam. I just need to get a small amount of naphtha to thin the coating before brushing it on. I was unable to find a local source for the aerosol can variety.

All of this is taking far longer than I imagined when I started day-dreaming about the project, but I'm trying to avoid any MORE rookie mistakes. My choices to re-style a proven design (Timn8ter's PC speakers), switch to a 0.5 way design, AND use hardwood panels have introduced a lot of uncertainty in the final results. Thanks again to those of you kind enough to help!

Hi,

The foam must be open cell - i.e. porous and sponge like.

Closed cell foam will not do at all.

🙂/sreten.

The foam must be open cell - i.e. porous and sponge like.

Closed cell foam will not do at all.

🙂/sreten.

Thanks again, sreten. The foam is open-cell. It's a little dense compared to the shredded and bonded urethane foam carpet underlayment sold in the US. This stuff is homogeneous, white, and spongy.

chicken & egg question...

I have several inductor values to try out for the lower driver filter AND some experimenting to do with damping. Is there an standard approach to sorting of both of these issues? For instance, should I choose my central inductor values (0.5mH) and listen to various damping combinations at that value before changing inductors? Or would it be preferable to damp with 3/4" foam and then vary the inductor values? I expect I'll need to do a lot of experimentation, I'm just trying to determine if there's a logical order that should guide me. I lack the experience to gage whether minor inductor changes or damping combinations will have a more significant impact on the final sound.

I have several inductor values to try out for the lower driver filter AND some experimenting to do with damping. Is there an standard approach to sorting of both of these issues? For instance, should I choose my central inductor values (0.5mH) and listen to various damping combinations at that value before changing inductors? Or would it be preferable to damp with 3/4" foam and then vary the inductor values? I expect I'll need to do a lot of experimentation, I'm just trying to determine if there's a logical order that should guide me. I lack the experience to gage whether minor inductor changes or damping combinations will have a more significant impact on the final sound.

Hi,

Just line the cabinets with foam - if you are concerned about

using too much then line the back, one side and top or bottom.

TBH is would be hard to use too much stuffing, the port may

be somewhat damped but this is good for transient response.

It is arm waving, but I think you will be fine with 0.5mH inductor.

As said before for a PC you can use PC EQ for fine tuning the

sound , a dip at 8khz is needed.

🙂/sreten.

Just line the cabinets with foam - if you are concerned about

using too much then line the back, one side and top or bottom.

TBH is would be hard to use too much stuffing, the port may

be somewhat damped but this is good for transient response.

It is arm waving, but I think you will be fine with 0.5mH inductor.

As said before for a PC you can use PC EQ for fine tuning the

sound , a dip at 8khz is needed.

🙂/sreten.

Many thanks!

I've moved everything to my workplace, and am sneaking out during early morning hours and at lunch to work on the cabs. I've just coated the interior panel surfaces with the plasti-dip "gunk" and will be applying the foam once it dries. I doubt the plasti-dip will make much of a difference, unless I used 3-4 coats. For that, the aerosol can would have been preferable. With some luck, I'll have the 1st box ready for finish sanding and lacquer by the end of the day. You've been tremendously helpful throughout this build, and I appreciate it.

squib

I've moved everything to my workplace, and am sneaking out during early morning hours and at lunch to work on the cabs. I've just coated the interior panel surfaces with the plasti-dip "gunk" and will be applying the foam once it dries. I doubt the plasti-dip will make much of a difference, unless I used 3-4 coats. For that, the aerosol can would have been preferable. With some luck, I'll have the 1st box ready for finish sanding and lacquer by the end of the day. You've been tremendously helpful throughout this build, and I appreciate it.

squib

squib said:Thanks again, sreten. The foam is open-cell. It's a little dense compared to the shredded and bonded urethane foam carpet underlayment sold in the US. This stuff is homogeneous, white, and spongy.

Hi, as long as it soaks up water like a sponge it will be fine, 🙂/sreten.

Okay, after a looooong pause, here's the 1st completed speaker

I've finally had some time to get back to this project. I thought I'd post a couple of pictures of the first completed speaker, for those of you that might still be curious. I'll post some interior shots of the 2nd box build, as I really just wanted to get this 1st one banged together.

The finish is just a satin lacquer - 4 coats. The Padauk is REALLY RED when sanded to fresh wood. From a moderate distance (~2 meters) it looks a lot like rosewood. Once you get up close you can see the open pores in the grain, but I think it still makes for a striking enclosure. If I had more woodworking skill, they might have been something special. As it is I'm vacillating between moderate pride at the end result and flashbacks to the paper-towel dispenser I made for mom in 8th grade shop class.🙄 Most of the glue joints are nice and tight, but the rear baffle gave me some real headaches. Hand sanding with a large sanding block evened out the adjoining panel-ends, but I rolled the outer edges just slightly, leaving a narrow gap in the edge of the joint. It's structurally secure, just not as aesthetically pleasing as the rest of the joints. By far the worst of the mistakes I made during construction was the hand cutting/sanding of the speaker cut-outs. No one will mistake them for a router job.

Squib

I've finally had some time to get back to this project. I thought I'd post a couple of pictures of the first completed speaker, for those of you that might still be curious. I'll post some interior shots of the 2nd box build, as I really just wanted to get this 1st one banged together.

The finish is just a satin lacquer - 4 coats. The Padauk is REALLY RED when sanded to fresh wood. From a moderate distance (~2 meters) it looks a lot like rosewood. Once you get up close you can see the open pores in the grain, but I think it still makes for a striking enclosure. If I had more woodworking skill, they might have been something special. As it is I'm vacillating between moderate pride at the end result and flashbacks to the paper-towel dispenser I made for mom in 8th grade shop class.🙄 Most of the glue joints are nice and tight, but the rear baffle gave me some real headaches. Hand sanding with a large sanding block evened out the adjoining panel-ends, but I rolled the outer edges just slightly, leaving a narrow gap in the edge of the joint. It's structurally secure, just not as aesthetically pleasing as the rest of the joints. By far the worst of the mistakes I made during construction was the hand cutting/sanding of the speaker cut-outs. No one will mistake them for a router job.

Squib

Attachments

I have some rear mounted speakers like yours and the midrange was a little harsh until I put a strip of adhesive wool felt around the inside of the cutout. You might want to experiment with that, you can get the strips from:

http://www.mcmaster.com/

although your finish is beautiful, so maybe do it in a way where it can be removed without leaving residue.

http://www.mcmaster.com/

although your finish is beautiful, so maybe do it in a way where it can be removed without leaving residue.

1st impressions of sound

Thanks for the suggestion. I've only tested this single speaker at low volume and my preliminary impressions support Sreten's suggestion that an eq notch around 8khz will be needed. I knew I was going to have to play with EQ to attenuate any output below 60-65hz, so a little touch-up in the HF is not a problem. If I can't arrive at an EQ solution, I'll be inclined to try the felt ring treatment. These are just PC speakers, and already sound much better than I expected.

A/B comparison with my Paradigm Atom V3's definitely indicates a little harshness in my single speaker. As expected, they are also far less efficient than the Atoms. I'm very happy to report that the upper bass is clean. I was quite worried that male vocals and voice (NPR news broadcasts) would sound "chesty"due to the overlapping output of both drivers. They don't. As to the harshness...it's not bad, but noticeable in direct comparison with the Atoms. I'm quite glad that the inductor is there to roll off the lower driver's HF. I'm guessing the harshness would be more pronounced without it. I'll be playing with them more once the second unit is completed.

Thanks for the suggestion. I've only tested this single speaker at low volume and my preliminary impressions support Sreten's suggestion that an eq notch around 8khz will be needed. I knew I was going to have to play with EQ to attenuate any output below 60-65hz, so a little touch-up in the HF is not a problem. If I can't arrive at an EQ solution, I'll be inclined to try the felt ring treatment. These are just PC speakers, and already sound much better than I expected.

A/B comparison with my Paradigm Atom V3's definitely indicates a little harshness in my single speaker. As expected, they are also far less efficient than the Atoms. I'm very happy to report that the upper bass is clean. I was quite worried that male vocals and voice (NPR news broadcasts) would sound "chesty"due to the overlapping output of both drivers. They don't. As to the harshness...it's not bad, but noticeable in direct comparison with the Atoms. I'm quite glad that the inductor is there to roll off the lower driver's HF. I'm guessing the harshness would be more pronounced without it. I'll be playing with them more once the second unit is completed.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Need advice for 1st project (Aura NS3)