One more question from a practicality standpoint regarding frequency...

I have one or two records that seem to have some kind of impurity in the vinyl. Thus far my newest one hasn't dislodged from vacuum cleaning, but I'm a little concerned about impurities breaking loose in an ultrasonic bath. It's a low number pressing so I'm not sure if I'll be able to get a replacement. I had one UK pressing of Chris Squire - Fish Out of Water that I loaned out to someone to have the record it for me a few years back, and what I'd thought was dirt when I sent it turned out to be one of these kind of flaws, making one side unplayable after it broke off.

So, anyone have any idea if this could be an issue, and if higher frequencies will be more or less likely to cause a problem?

I have one or two records that seem to have some kind of impurity in the vinyl. Thus far my newest one hasn't dislodged from vacuum cleaning, but I'm a little concerned about impurities breaking loose in an ultrasonic bath. It's a low number pressing so I'm not sure if I'll be able to get a replacement. I had one UK pressing of Chris Squire - Fish Out of Water that I loaned out to someone to have the record it for me a few years back, and what I'd thought was dirt when I sent it turned out to be one of these kind of flaws, making one side unplayable after it broke off.

So, anyone have any idea if this could be an issue, and if higher frequencies will be more or less likely to cause a problem?

Have you checked out NextFab in Philly, Packgrog? I don't know exactly what they have, but the concept appears similar to TechShop.

About NextFab

Cheers,

B B

FYI, one place to look is for makerspaces, such as here: Makerspace | Directory

You may need to do a Find on the page for your city. These spaces are generally attractively priced, have a decent range of equipment (my local here in Portsmouth NH has a 3-D printer, which is pretty good for such a small town) and there are a lot around the country and world. They often hold classes too.

Aside from NextFab in Philly, there is also Hive76, Philadelphia Woodworks and in the future, possibly Massive, 8-story live/work makerspace planned for South Philly - Technical.ly Philly

Niiiice! Thanks to you both. Lots of good stuff there to explore. The one in Media, PA would be easier to access (I'm in the 'burbs, rather than Philly proper), though it looks more geared toward kids. Lots of Philly options though, and even something in Lancaster, which is a hike but not unreachable.

I'm also considering more simplified approaches than bbftx's build, and closer to either the "Vinyl Clean" or ultrasonicrecords.com approach. Not as sturdy looking, but probably easier to build with limited tools.

And kudos on Portsmouth, Carlp! The wife and I made a special trip up there this past summer since we loved our brief stop off there so much on a previous trip up to Portland, ME. Really cool little town!

But back on topic, thanks again for the links! Excellent starting point, whether for THIS project or others entirely. That Philadelphia Woodworks one looks especially tempting! I've always been a sucker for nice woodwork, and being able to produce some of it myself would be insanely cool. Cheers!

Still curious about the ultrasonic vs. vinyl impurity issue, though. If anyone is able to test with a cheap, crummy LP with a visible impurity, that would be very helpful.

I'm also considering more simplified approaches than bbftx's build, and closer to either the "Vinyl Clean" or ultrasonicrecords.com approach. Not as sturdy looking, but probably easier to build with limited tools.

And kudos on Portsmouth, Carlp! The wife and I made a special trip up there this past summer since we loved our brief stop off there so much on a previous trip up to Portland, ME. Really cool little town!

But back on topic, thanks again for the links! Excellent starting point, whether for THIS project or others entirely. That Philadelphia Woodworks one looks especially tempting! I've always been a sucker for nice woodwork, and being able to produce some of it myself would be insanely cool. Cheers!

Still curious about the ultrasonic vs. vinyl impurity issue, though. If anyone is able to test with a cheap, crummy LP with a visible impurity, that would be very helpful.

I'm a little concerned about impurities breaking loose in an ultrasonic bath. ...

I had one UK pressing of Chris Squire - Fish Out of Water that I loaned out to someone to have the record it for me a few years back, and what I'd thought was dirt when I sent it turned out to be one of these kind of flaws, making one side unplayable after it broke off.

So, anyone have any idea if this could be an issue, and if higher frequencies will be more or less likely to cause a problem?

Thanks for the resources, Carl. I was going to suggest "Makers" groups too. They often have people willing to assist on projects with their own gear.

Pack: Higher frequencies will be less likely to cause a problem in that situation than low freq. But I've never experienced such an LP.

My guess is the impurity was on the mold when the record was pressed. It could come out at any time, URC or not. If anything, just playing the record is probably more likely to dislodge it. The needle on your LP exerts very high local pressures -- many thousands of psi.

Probably best to be very careful with that LP.

B B

I had an epiphany about using 1" Aluminum T-Slotted Framing to build a stand for a vertical sliding motor mount, eliminating my need for sawing, etc. It'd be clean, sturdy, waterproof, and potentially almost wife-friendly. The Linear Bearing and associated Hand Brake are the killers, though, at about $54. With 3 12" and one 24" frame pieces and simple fastener plates and screws, the lowest I could get it at McMaster-Carr is $100 before shipping. Brutal. That's BEFORE even looking into motor or filter parts. Rough. Anyone know of any less expensive suppliers for similar gear?

Pack, It might help if you draw out what you're contemplating. I can't envision what exactly you're doing with three 12" and one 24" extrusions. And why do you need a linear bearing and hand brake? There are cheaper alternatives, but again, I'm not sure what you have in mind.

The T-slot framing route is a convenient way to go, but you might consider smaller alternatives to 1"x1" profiles, like MakerBeam, or OpenBeam. They should be cheaper than anything at McMaster-Carr.

B B

The T-slot framing route is a convenient way to go, but you might consider smaller alternatives to 1"x1" profiles, like MakerBeam, or OpenBeam. They should be cheaper than anything at McMaster-Carr.

B B

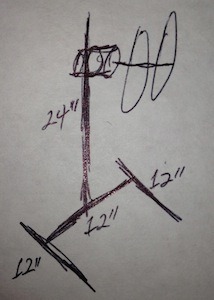

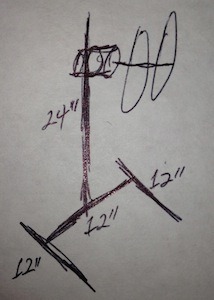

Well, here's my turtle-with-Parkinson's-quality drawing:

The 12" pieces forming a base, and the 24" piece functioning as a motor mount. The (obnoxiously expensive for my expectations) linear bearing and hand brake is thus far the best thing I've found that could serve as a motor mount that could be easily unlocked and slid up or down, similar to the tripod idea someone else posted, but without the annoyance of motion in other directions.

The disadvantage of the MakerBeam is that they don't seem that much cheaper if, as in my case, you only need a small subset of the parts. Still a little over $50 just for the frame, while having a fair number of spare parts left over (mostly all the bolts), and that still doesn't solve the motor mount issue. OpenBeam doesn't have small enough packages. Nice that they DO make (approximately) half-inch extrusions, though, as the 1" is definitely overkill.

Thoughts? Am I barking up the wrong proverbial tree here?

The 12" pieces forming a base, and the 24" piece functioning as a motor mount. The (obnoxiously expensive for my expectations) linear bearing and hand brake is thus far the best thing I've found that could serve as a motor mount that could be easily unlocked and slid up or down, similar to the tripod idea someone else posted, but without the annoyance of motion in other directions.

The disadvantage of the MakerBeam is that they don't seem that much cheaper if, as in my case, you only need a small subset of the parts. Still a little over $50 just for the frame, while having a fair number of spare parts left over (mostly all the bolts), and that still doesn't solve the motor mount issue. OpenBeam doesn't have small enough packages. Nice that they DO make (approximately) half-inch extrusions, though, as the 1" is definitely overkill.

Thoughts? Am I barking up the wrong proverbial tree here?

Last edited:

On the other hand, I'm quite tempted just to get the MakerBeam Starter Kit and simple motor bracket, and tinker for the hell of it. More expensive, but looks like just plain FUN!

http://www.amazon.com/gp/product/B00G3J6GDM/

http://www.amazon.com/gp/product/B00G2DNVH8/

I also wonder if that would be enough parts to build a frame that could hold the motor, pump, AND filter assemblies all on one bracket, keeping things a bit more tidy... >🙂

EDIT: Purchased. Whether I build this or something else, this should be fun regardless.

http://www.amazon.com/gp/product/B00G3J6GDM/

http://www.amazon.com/gp/product/B00G2DNVH8/

I also wonder if that would be enough parts to build a frame that could hold the motor, pump, AND filter assemblies all on one bracket, keeping things a bit more tidy... >🙂

EDIT: Purchased. Whether I build this or something else, this should be fun regardless.

Last edited:

Packgrog, Here's an alternative source that could potentialy work for you.

https://www.servocity.com/html/channel___brackets.html

https://www.servocity.com/html/mini_aluminum_channel.html#.VLGLemt5mSM

https://www.servocity.com/html/channel___brackets.html

https://www.servocity.com/html/mini_aluminum_channel.html#.VLGLemt5mSM

Pack, I think you can make something work out of that kit!

If one wanted to go a cheaper route, I'd go OpenBeam 15x15mm profile. It's designed to use off the shelf nuts, bolts, etc. Drawing attached.

I'd get:

8 pack of 270mm beams for $26

6 straight connectors ~$4

4 Tee connectors ~$4 (assuming each side to cross piece is rigid with only one tee)

24 Nuts & 24 bolts ~$3

That's about $37 for a frame along the lines you were thinking.

But your kit will be more fun and can be used for other part of the project too.

good luck

B B

If one wanted to go a cheaper route, I'd go OpenBeam 15x15mm profile. It's designed to use off the shelf nuts, bolts, etc. Drawing attached.

I'd get:

8 pack of 270mm beams for $26

6 straight connectors ~$4

4 Tee connectors ~$4 (assuming each side to cross piece is rigid with only one tee)

24 Nuts & 24 bolts ~$3

That's about $37 for a frame along the lines you were thinking.

But your kit will be more fun and can be used for other part of the project too.

good luck

B B

Last edited:

Erg. Well it seems that the pump listed in bb's part list has skyrocketed in price. The cheapest I've found it thus far is $56, BEFORE parts for a case. Nuts. I suppose that it's equally feasible to get the Attwood Potable Water Pump that Ishmail uses and hack-wire it with some RatShack-quality AC-to-DC adapter for a little less money, but that means extra wires, etc. Not quite ideal.

We continue to receive positive support and interest in our Vibrato Ultrasonic Cleaners, which makes us question our decision to cease manufacturing!

I'd like to pose some questions to our followers and supporters:

1) Would you be interested in purchasing the circuit boards to build your own ultrasonic cleaner?

2) Do you have enough electronic experience to build an ultrasonic cleaner?

3) Would you prefer a completed/working ultrasonic cleaner available for purchase?

4) What type of enclosure would you prefer - plastic, metal, wood, etc.?

5) What frequency ultrasonic cleaner do you prefer - 40khz, 60khz, 80khz, 135khz ?

6) What do you intend to clean with an ultrasonic cleaner?

7) What features are you looking for - simple on/off timer? Digital Display Timer? Heated tank? Digital heater controller? Frequency Sweep? Dual frequency (40khz/60khz, 60khz/80khz) ?

Instead of filling up this forum with answers that are off-topic, you may email them to me, at louis(at)vibratollc.com

Thank you, and I apologize for the spam.

Louis Steele

Vibrato, LLC.

Email sent.

Andy

Ordered the Herbach motor. Shipping is kind of nasty, adding another $9 or so, as apparently UPS is the only option available.

I also spotted this site for the 9/32" diameter rod stock, which allows for custom lengths, for those of us without the ability to cut a 3' length down to something manageable.

Speedy Metals 9/32" 303 Stainless Steel Round

Haven't ordered yet since I'll have to mount the motor first to know the necessary length. Thought that others might find that link useful, though.

I also spotted this site for the 9/32" diameter rod stock, which allows for custom lengths, for those of us without the ability to cut a 3' length down to something manageable.

Speedy Metals 9/32" 303 Stainless Steel Round

Haven't ordered yet since I'll have to mount the motor first to know the necessary length. Thought that others might find that link useful, though.

Placed an order yesterday with Findings Outlet for the Sonix IV ST136H ($499 + $28.32 shipping). Here's hoping I won't have to wait too long. Only been a day, but order is still in "Processing". Anyone have any experience with this site and know what the average wait time might be?

For actual motor and spindle mounting and stability, ServoCity seems to have the goods. Currently pondering the following, but resisting pulling the trigger pending any ideas from the peanut gallery...

1/4 inch x8 inch Precision Shaft ($2.69): Spindle. Duh, super easy to just source from here.

1/8 inch to 1/4 inch Set Screw Shaft Coupler ($4.99): For attaching the spindle to the motor.

1/4 inch Ball Bearing Quad Pillow Block ($6.49): For providing bracing for the spindle, avoiding strain on the coupler or motor.

1.50 inch Aluminum Channel ($2.99): For holding the bearing and motor mount securely together.

90 Degree Dual Side Mount A (2 pack) ($5.99): For (somehow) rigidly attaching the motor assembly to the channel above.

1/4inch Aluminum Clamping Collar ($4.99): Shaft stop for first spacer.

.1875 in L x 6-32 Zinc-Plated Alloy Steel Socket Head Cap Screw (25 pk) ($1.59)

Shipping is nicely reasonable (yay, USPS!). Part of me is regretting not paying better attention to Zg925's recommendations throughout this massive thread, as going for the cheaper motor he posted, as well as possibly going more pure ServoCity parts rather than the MakerBeam/ServoCity mix this will end up becoming, may have saved me some money and annoyance. Got too excited to get started, I guess. 😛

First pass will probably involve a rigid mount of the motor, rather than the sliding action that I'd hoped for, as I'm hesitant to scratch up the black MakerBeams by just keeping some of the bolts loose (even with some WD-40 in the relevant track), and Amazon appears to be out of stock of the bearing kit. I suspect the whole assembly will be light enough to just pick up and lift up and away from the tank, so I'm not too concerned, but it's not ideal. Assuming all of the ordered parts are delivered, I'm already looking at about $730 total cost. Definitely more than I'd hoped, and that's before filtration (though admittedly the Sonix is the bulk of the cost, here, unlike the turnkey options that all use cheaper 40kHz tanks). Still, that's about on par for the more popular vacuum-based options, with far less operational hassle, and likely better results, so still a likely win.

Anyone tried a different pump option than the ones used by BB or Ishmail? I saw a post about a $30-40 pump that someone found, but didn't spot a follow-up about if it worked out. [EDIT: ie: doublenaught's Shurflo pump, any others?] Any other thoughts or suggestions?

For actual motor and spindle mounting and stability, ServoCity seems to have the goods. Currently pondering the following, but resisting pulling the trigger pending any ideas from the peanut gallery...

1/4 inch x8 inch Precision Shaft ($2.69): Spindle. Duh, super easy to just source from here.

1/8 inch to 1/4 inch Set Screw Shaft Coupler ($4.99): For attaching the spindle to the motor.

1/4 inch Ball Bearing Quad Pillow Block ($6.49): For providing bracing for the spindle, avoiding strain on the coupler or motor.

1.50 inch Aluminum Channel ($2.99): For holding the bearing and motor mount securely together.

90 Degree Dual Side Mount A (2 pack) ($5.99): For (somehow) rigidly attaching the motor assembly to the channel above.

1/4inch Aluminum Clamping Collar ($4.99): Shaft stop for first spacer.

.1875 in L x 6-32 Zinc-Plated Alloy Steel Socket Head Cap Screw (25 pk) ($1.59)

Shipping is nicely reasonable (yay, USPS!). Part of me is regretting not paying better attention to Zg925's recommendations throughout this massive thread, as going for the cheaper motor he posted, as well as possibly going more pure ServoCity parts rather than the MakerBeam/ServoCity mix this will end up becoming, may have saved me some money and annoyance. Got too excited to get started, I guess. 😛

First pass will probably involve a rigid mount of the motor, rather than the sliding action that I'd hoped for, as I'm hesitant to scratch up the black MakerBeams by just keeping some of the bolts loose (even with some WD-40 in the relevant track), and Amazon appears to be out of stock of the bearing kit. I suspect the whole assembly will be light enough to just pick up and lift up and away from the tank, so I'm not too concerned, but it's not ideal. Assuming all of the ordered parts are delivered, I'm already looking at about $730 total cost. Definitely more than I'd hoped, and that's before filtration (though admittedly the Sonix is the bulk of the cost, here, unlike the turnkey options that all use cheaper 40kHz tanks). Still, that's about on par for the more popular vacuum-based options, with far less operational hassle, and likely better results, so still a likely win.

Anyone tried a different pump option than the ones used by BB or Ishmail? I saw a post about a $30-40 pump that someone found, but didn't spot a follow-up about if it worked out. [EDIT: ie: doublenaught's Shurflo pump, any others?] Any other thoughts or suggestions?

Last edited:

Hi PG, You might consider using the dual ball bearing hub instead the single bearing Quad pillow block. Link:

Dual Bearing Hub at ServoCity

Reason being, a dual bearing eliminates the cantilever load seen by the motor, while a skinny single bearing like the one you listed still presents a big load (upward) where the shaft meets the motor. I finessed this somewhat in my build by using a "longer" bushing, which to an extent mimics a dual bearing arrangement.

B B

Dual Bearing Hub at ServoCity

Reason being, a dual bearing eliminates the cantilever load seen by the motor, while a skinny single bearing like the one you listed still presents a big load (upward) where the shaft meets the motor. I finessed this somewhat in my build by using a "longer" bushing, which to an extent mimics a dual bearing arrangement.

B B

Unless I used a 3" channel instead of the 1.5" (which seems to be out of stock now) along with two Quad pillow blocks spaced a little further apart to provide extra stability. Or do you think that would still be less effective than the dual bearing hub? Either way, I feel like the open part of the channel needs some form or bracing, which is why the Quad pillow block appealed to me, with both bearing and bracing already built into the part. Thoughts?

PG, I'm not personally familiar with the ServoCity channel stuff, so I really can't comment on strength and bracing issues.

You'd be fine with either the dual bearing or two of the pillow-blocks. Just looking at the photos, I think the dual bearing is a little more compact and perhaps more cost-efficient. But either option will work fine I think.

And Darn You! You've got my mind churning to the extent I'm thinking of building another version of a setup. I really don't have the time, but I've got the urge to do a free-standing frame like you're working on, that could be used with a wide-variety of cleaners. I'd use square aluminum tubing, which is quite cheap compared to these engineered extrusions and channels. Different sizes of the right kind of tubing can be used to create a smoothly telescoping column that holds the motor and hub setup. (Just a single, strong pin to be pulled and inserted to move the column up or down and support it.)

Although it's really not necessary with the telescoping column, I'm also leaning toward doing a magnetic shaft coupling arrangement, just for the flexibility it would afford. I also have ID'd a speargun part with a to-spec 9/32" diameter that could be used for the spindle in place of the ¼" options that need to be used by those without machining capabilities.

And finally, I'm thinking of designing this to be usable with the larger Sonix ST-126 10 quart unit. It's wider than the 136 model, and has one more ultrasonic transducer (4 in total). This tank should allow for 5 LPs to be cleaned at once, with proper spacing and power-to-surface-area ratio.

Best,

B B

You'd be fine with either the dual bearing or two of the pillow-blocks. Just looking at the photos, I think the dual bearing is a little more compact and perhaps more cost-efficient. But either option will work fine I think.

And Darn You! You've got my mind churning to the extent I'm thinking of building another version of a setup. I really don't have the time, but I've got the urge to do a free-standing frame like you're working on, that could be used with a wide-variety of cleaners. I'd use square aluminum tubing, which is quite cheap compared to these engineered extrusions and channels. Different sizes of the right kind of tubing can be used to create a smoothly telescoping column that holds the motor and hub setup. (Just a single, strong pin to be pulled and inserted to move the column up or down and support it.)

Although it's really not necessary with the telescoping column, I'm also leaning toward doing a magnetic shaft coupling arrangement, just for the flexibility it would afford. I also have ID'd a speargun part with a to-spec 9/32" diameter that could be used for the spindle in place of the ¼" options that need to be used by those without machining capabilities.

And finally, I'm thinking of designing this to be usable with the larger Sonix ST-126 10 quart unit. It's wider than the 136 model, and has one more ultrasonic transducer (4 in total). This tank should allow for 5 LPs to be cleaned at once, with proper spacing and power-to-surface-area ratio.

Best,

B B

Last edited:

Eeeeexellent, Smithers! *waggles fingers* 😛And Darn You! You've got my mind churning to the extent I'm thinking of building another version of a setup. I really don't have the time, but I've got the urge to do a free-standing frame like you're working on, that could be used with a wide-variety of cleaners. I'd use square aluminum tubing, which is quite cheap compared to these engineered extrusions and channels. Different sizes of the right kind of tubing can be used to create a smoothly telescoping column that holds the motor and hub setup. (Just a single, strong pin to be pulled and inserted to move the column up or down and support it.)

Always happy to inspire more thought and more conversation. Mutual growth freakin' rules. 🙂

And your idea is pretty much my original idea, but I just haven't found good sources for the relevant parts, and went down a totally different route due to the limited tool availability. I'm eager to see what you come up with! And as I said previously, I'm curious if you might be able to come up with a version of your current build that could be more tank-agnostic, with adjustable frame dimensions. That'd be cool as well.

Meanwhile, I guess I'm stuck until ServoCity has more 1.5" inch Aluminum Channels available, as the 3" channel just doesn't seem appropriate for my goal. Meh.

Holy crap! The tank arrived today! Some questionable packing materials (checkbook boxes?!), a box that had clearly been opened once before, and one metal fin on the bottom of the tank that's bent, as well as no email notification beyond the original order receipt, but freakin' fast shipping! This was the last thing that I expected to arrive. Well, here's hoping that the tank is properly operational, and that my ServoCity order arrives Saturday. I could potentially have a first run trial this weekend, far sooner than I'd anticipated. *crosses fingers*

OK, assuming I can at least kludge a spindle this weekend, I may actually be trying this out, which means time to focus on the fluid.

There's quite a few posts on this throughout the thread, but people's choice of concentrations seems to have evolved. Those of you who have been doing this for a while, what are your prefered concentrations of IPA (isopropyl alcohol) and Photo-Flo/whatever? Looks like I've got 70% IPA that the wife uses, and I'm wondering how much I should add per gallon of distilled water. A cap-full? Less? Photo-Flo looks to be available on Amazon Marketplace, but that's not arriving this weekend if I order it. Any and all thoughts on this would be appreciated, and perhaps should be added to some kind of FAQ related to the thread.

There's quite a few posts on this throughout the thread, but people's choice of concentrations seems to have evolved. Those of you who have been doing this for a while, what are your prefered concentrations of IPA (isopropyl alcohol) and Photo-Flo/whatever? Looks like I've got 70% IPA that the wife uses, and I'm wondering how much I should add per gallon of distilled water. A cap-full? Less? Photo-Flo looks to be available on Amazon Marketplace, but that's not arriving this weekend if I order it. Any and all thoughts on this would be appreciated, and perhaps should be added to some kind of FAQ related to the thread.

- Home

- Source & Line

- Analogue Source

- My version of an Ultrasonic Record Cleaner