Hello njjano,

Your pictures look horrific. I would not clean LPs in your tank.

My guess is the tank is not made out of high quality stainless steel. The photos make it look like the surface of the entire tank is not smooth, like stainless steel usually is. (This is a separate observation from your comment about the fine sandpaper feel.) There is no telling what kind of metal was used for the tank, and I would not use it for any ultrasonic cleaning, of anything.

Good luck,

B B

Your pictures look horrific. I would not clean LPs in your tank.

My guess is the tank is not made out of high quality stainless steel. The photos make it look like the surface of the entire tank is not smooth, like stainless steel usually is. (This is a separate observation from your comment about the fine sandpaper feel.) There is no telling what kind of metal was used for the tank, and I would not use it for any ultrasonic cleaning, of anything.

Good luck,

B B

Hello njjano,

Your pictures look horrific. I would not clean LPs in your tank.

My guess is the tank is not made out of high quality stainless steel. The photos make it look like the surface of the entire tank is not smooth, like stainless steel usually is. (This is a separate observation from your comment about the fine sandpaper feel.) There is no telling what kind of metal was used for the tank, and I would not use it for any ultrasonic cleaning, of anything.

Good luck,

B B

Well the photos are very bad, I have some issues with my lab desk lighting and this temporary solution is... well, far not perfect. Still waiting for the replacement devices...

Actually the situation is not that bad. Don't forget that the tank is filled with about 12L of continuously circulated (cooled and filtered) water while these spots are small, like a 10-12mm diameter on the biggest one (around 3/8 - 1/2"). The result of cleaning is exceptional, so this phenomenon is not degrading the effectiveness of vinyl cleaning at all. The tank's internal surface is nice and smooth, these pictures were taken just after a weekend long cleaning session, so the tank was still wet and again the lighting was not at it's best.

Anyway it might be possible that you're right and the material is just not good enough for this application or, maybe the transducers are really powerful 😀

I'd be happy to read Mr. Vibrato's opinion (sorry I can't recall his name... 🙁 ) as he could have first hand info regarding these failures.

Hey,

This is so inspiring and I would like to build one by my self too. Thank you for sharing this information. Can someone give more incites on this topic?

This is so inspiring and I would like to build one by my self too. Thank you for sharing this information. Can someone give more incites on this topic?

Dear all,

I've discovered some strange, dark spots on the bottom of the bowl, where the transducers are installed (on the other side). My machine is still in experimental phase (a year ago or more...) but has already several hours of operation. Some time ago I noticed only one slight spot (the one which is now the strongest one) and by accumulating more and more operation hours, now I've got these spots on all the transducer's fixing points. If you touch them it feels like a very fine sanding paper (like 1000 or more). I suppose it is a kind of erosion.

Anybody else experienced something like this?

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

njjano:

The spots are where metal studs are welded to the tank and the transducers are then screwed onto the studs with epoxy.

This does look like the beginnings of "cavitation erosion", which will eventually lead to holes in the tank.

For these more powerful 40khz frequency ultrasonic cleaners, a thicker gauge tank should really be used, such as 22ga or 18ga, instead of 24ga.

You may be able to lessen the appearance of the dark spots by cleaning the inside of the tank with stainless-steel cleaner. You may even try "Soft Scrub", provided you clean out all the residue and use the stainless-steel cleaner afterwards.

-Louis

Vibrato, LLC.

Thanks Louis. Love the cleaner I just bought from you. Works great! I'm using a 1 rpm disco ball motor. I know others are using 5 rph motors but my 1 rpm is producing great results. I had some very old LPs that were basically unlistenable. Now they're very good.

I've read through quite a bit of this thread, but there's so many conflicting views, options, etc, I was hoping someone would be kind enough to quickly summarize and clarify a few points for me.

My plan is to keep things as simple as possible while still achieving the features that I want.

I just want a small tank that can clean one record at a time, and I plan on using either Tergitol 15-S-7 or the blend of Tergitol 15-S-3/15-S-9, whichever is less expensive for me. I will use deionized water.

Is 40, 60, or 80 kHz better for cleaning? In terms of the cavitation size, it seems any will work, but I see some people insisting higher is better. I noted that the higher the frequency is, the more uniform the cavitations become, instead of happening in random spots in the bath.

Some really push using the heater to increase solubility of contaminants. Is this necessary when using real Tergitol?

For cleaning the one record at a time, which tank/brand would be best? I don't want to spend a lot on the tank, a little cheapie would be best.

I see some people mentioning "tide lines" and other left over debris. How do I avoid this?

Are there any tanks that are very narrow so that I can use a smaller amount of solution and not have to bother with filtering it? Or would this introduce too much variable heat and warp the record?

If so, what is an inexpensive 1 micron filter and pump that could be used? Also, if this is truly removing built up contaminants beyond just dust, etc, then the filter isn't going to remove things like oil - will this be redeposited, or will the Tergitol keep it viable for 20 or so washings?

Finally, how many rpm's/rph should the motor be doing? And then, for how long should it be left to run?

Sorry, if these have been answered before. I'd just like to see what the general consensus is since I've seen so many answers. Thanks to anyone who takes the time to help.

My plan is to keep things as simple as possible while still achieving the features that I want.

I just want a small tank that can clean one record at a time, and I plan on using either Tergitol 15-S-7 or the blend of Tergitol 15-S-3/15-S-9, whichever is less expensive for me. I will use deionized water.

Is 40, 60, or 80 kHz better for cleaning? In terms of the cavitation size, it seems any will work, but I see some people insisting higher is better. I noted that the higher the frequency is, the more uniform the cavitations become, instead of happening in random spots in the bath.

Some really push using the heater to increase solubility of contaminants. Is this necessary when using real Tergitol?

For cleaning the one record at a time, which tank/brand would be best? I don't want to spend a lot on the tank, a little cheapie would be best.

I see some people mentioning "tide lines" and other left over debris. How do I avoid this?

Are there any tanks that are very narrow so that I can use a smaller amount of solution and not have to bother with filtering it? Or would this introduce too much variable heat and warp the record?

If so, what is an inexpensive 1 micron filter and pump that could be used? Also, if this is truly removing built up contaminants beyond just dust, etc, then the filter isn't going to remove things like oil - will this be redeposited, or will the Tergitol keep it viable for 20 or so washings?

Finally, how many rpm's/rph should the motor be doing? And then, for how long should it be left to run?

Sorry, if these have been answered before. I'd just like to see what the general consensus is since I've seen so many answers. Thanks to anyone who takes the time to help.

Last edited:

Alliexandras,

I'll offer my thoughts on several of your questions.

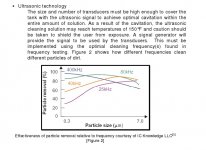

• Higher frequencies clean better for the particle sizes likely to be of interest in record grooves on LPs. This is supported by research. See the attached graph, which shows 80khz is much more effective at removing particles in the micron range. At 2 micron, an 80khz machine will remove about 90% of the particles, while 25khz or 40khz machines at best will remove 60 to 70% of the same particles.

• Empirical and research results across hundreds of users cleaning different items suggest heat helps cleaning regardless of solution formulation used.

• Good research also shows distribution of cavitation bubbles is improved as temperature rises, and most importantly, that at higher temps, there is less erosion of parts you're trying to clean!

• "A little cheapie" will not give you good results IMO. At best, it will be compromised in particle removal ability since it will be a 25khz or 40khz machine, or a 25khz machine masquerading as a 40khz machine (see the first bullet). There have also been examples mentioned on the board of damage caused by cheapie machines. Not worth the risk in my opinion. But there will be people who disagree, as you have seen, since they might have rolled the dice and procured a machine that seems to work for them.

• There are narrow machines for rifle barrels and such, but they aren't any cheaper than the usual 6 qt machines. And therefore, why bother cleaning only 1 record at a time, when you can clean several and save time, and cleaning solution, in the long run?

• Do not plan on cleaning 1 record at a time, and just leaving your cleaning solution sitting around for your next listening session. It will get gross in a day or two. Deionized water gets ionized pretty quickly too by the way. Cleaning in batches is more efficient and saves time and money.

• Filtering is optional. It makes sense if you have a lot of LPs to clean. It then saves money.

• I am the original proponent of single revolution cleaning. Given a desired cleaning time of 3 to 4 minutes in the ultrasonic bath, which the literature indicates should be adequate for relatively clean items like LPs, that implies a 5 or 6 rph motor (assuming about ⅓ of the LP is submerged at any instant). A 1 rpm motor will only keep a point of the surface in the bath for about 20 seconds. This isn't long enough to remove most contaminants. That spot will then dry in the open air for 40 seconds. Another 20 seconds in the bath really isn't additive to the first 20 seconds in the bath. It's just another time period that's too short to remove many contaminants and they'll just remain on the record for the next spin too. Others are satisfied with the results they get at 1 rpm, so to each his own.

Good luck,

B B

Good luck

I'll offer my thoughts on several of your questions.

• Higher frequencies clean better for the particle sizes likely to be of interest in record grooves on LPs. This is supported by research. See the attached graph, which shows 80khz is much more effective at removing particles in the micron range. At 2 micron, an 80khz machine will remove about 90% of the particles, while 25khz or 40khz machines at best will remove 60 to 70% of the same particles.

• Empirical and research results across hundreds of users cleaning different items suggest heat helps cleaning regardless of solution formulation used.

• Good research also shows distribution of cavitation bubbles is improved as temperature rises, and most importantly, that at higher temps, there is less erosion of parts you're trying to clean!

• "A little cheapie" will not give you good results IMO. At best, it will be compromised in particle removal ability since it will be a 25khz or 40khz machine, or a 25khz machine masquerading as a 40khz machine (see the first bullet). There have also been examples mentioned on the board of damage caused by cheapie machines. Not worth the risk in my opinion. But there will be people who disagree, as you have seen, since they might have rolled the dice and procured a machine that seems to work for them.

• There are narrow machines for rifle barrels and such, but they aren't any cheaper than the usual 6 qt machines. And therefore, why bother cleaning only 1 record at a time, when you can clean several and save time, and cleaning solution, in the long run?

• Do not plan on cleaning 1 record at a time, and just leaving your cleaning solution sitting around for your next listening session. It will get gross in a day or two. Deionized water gets ionized pretty quickly too by the way. Cleaning in batches is more efficient and saves time and money.

• Filtering is optional. It makes sense if you have a lot of LPs to clean. It then saves money.

• I am the original proponent of single revolution cleaning. Given a desired cleaning time of 3 to 4 minutes in the ultrasonic bath, which the literature indicates should be adequate for relatively clean items like LPs, that implies a 5 or 6 rph motor (assuming about ⅓ of the LP is submerged at any instant). A 1 rpm motor will only keep a point of the surface in the bath for about 20 seconds. This isn't long enough to remove most contaminants. That spot will then dry in the open air for 40 seconds. Another 20 seconds in the bath really isn't additive to the first 20 seconds in the bath. It's just another time period that's too short to remove many contaminants and they'll just remain on the record for the next spin too. Others are satisfied with the results they get at 1 rpm, so to each his own.

Good luck,

B B

Good luck

Attachments

I agree with BB. I would like to add my experiences with the various frequencies with ultrasonic machines. I have several both 60 & 80 KHZ. I find the 80 not to be that great on really dirty records. While the cavitation are smaller in size the implosions are not as powerful to knock the grit off as a 60. However I might add that a very nasty record is going to require some physical intervention with a standard cleaner like a Knitty Gritty, VPI, Spin Clean, hand or such before running in a US cleaner. A record that has been treated well and looks clean would be fine in an 80 and slighty less loved record will do well in a 60 any thing else more likely need a multi pronged approach to cleaning. I use a distilled water and 99% isopropyl alcohol with 2 oz per quart. Vibrato LLC has some excellent cleaners or you may be able to find an early version Sonix IV on Ebay. The current Sonix ones are OEMed ones from China and are 40KHZ.

Thanks for the responses! I actually managed to find a Tuttnauer CSU3 (60Khz) fairly cheap, from a surplus, and I'll just buy a silicone rubber adhesive heater for it.

As a side note, I would be wary of using isopropyl alcohol in these machines - it's flash point is only ~ 55 F, meaning the vapors it gives off become flammable at that temperature, so you might end up causing an explosion. They make medical blast-proof tanks explicitly for that purpose.

As a side note, I would be wary of using isopropyl alcohol in these machines - it's flash point is only ~ 55 F, meaning the vapors it gives off become flammable at that temperature, so you might end up causing an explosion. They make medical blast-proof tanks explicitly for that purpose.

Is that 2oz IPA plus 30oz distilled water make up a quart (so 1:15 ratio) ... or do you mean 2oz IPA for every quart of distilled water (so 1:16 ratio)? 🙂I use a distilled water and 99% isopropyl alcohol with 2 oz per quart.

I use a slightly lower ratio - 400ml of IPA with 7800ml of distilled water.

The current Sonix ones are OEMed ones from China and are 40KHZ.

Tragic that Sonix has stopped making their own (good ones) and now merely imports Chinese cr*p. 🙁

Louis's ones (Vibrato LLC) are the ones to go for! 🙂

Andy

As a side note, I would be wary of using isopropyl alcohol in these machines - it's flash point is only ~ 55 F, meaning the vapors it gives off become flammable at that temperature, so you might end up causing an explosion.

AIUI, that 55F flashpoint is why - for safety - you use only a 5% solution of IPA?

Andy

Is that 2oz IPA plus 30oz distilled water make up a quart (so 1:15 ratio) ... or do you mean 2oz IPA for every quart of distilled water (so 1:16 ratio)? 🙂 Andy

To clarify, I use 1oz (not 2, brain fart!) per 1 quart of distilled. Basically 6 oz per tankful. The IPA is 99% pure electronics cleaning grade. Been using that for awhile with heat applied in an open room with no problems. I've upgraded a couple of my Sonix US cleaners with silicon heaters, they work great.

Alliexandras, Good find on the 60KHZ tank. We'll be interested to hear your results and see your setup.

Last edited:

To clarify, I use 1oz (not 2, brain fart!) per 1 quart of distilled. Basically 6 oz per tankful. The IPA is 99% pure electronics cleaning grade. Been using that for a while with heat applied in an open room with no problems.

Aaah, OK - so 1:32 ... a bit less than my mixture of 1:20 (using 99% IPA as well).

I use it with my heated 60kHz Sonix IV with no problems so far. 🙂

Andy

Has anyone used anti-redeposition agents in their solutions? Because of aggregation, the surfactant micelles can get pretty large, so I'm worried using a filter will remove it. Been looking at maleic anhydride copolymers or a sodium carboxymethylcellulose compound, but not sure how they will interact with Tergitol or with the record itself.

Last edited:

How does degritter compare to the DIY USC. I have a Sonix IV system that I built myself. Was wondering if I should upgrade due to the 120 kHz.

Thanks

Thanks

How does degritter compare to the DIY USC. I have a Sonix IV system that I built myself. Was wondering if I should upgrade due to the 120 kHz.

Thanks

IMO you are more that fine with the Sonix as long as it is the older 60 KHZ unit and no the current Chinese made ones. I also feel the 120 KHZ will not be aggresive enough. I have an 80 KHZ and I only use it on already "clean" records as I have found that a really dirty record just does not get cleaned as well (my results with Sonix and Vibrato cleaners).

Any thoughts on the iSonic line of USCs that have popped up on Amazon? We recently bought the 10 disc model and have been tinkering around with it. Quickly found that for my needs a filtration system is a must as we get in tons of used vinyl. Just ordered the parts to do a similar setup to TIMA. Will post pictures when done. So far seems the efficiency and cleanliness are just what what my shop needs to process vinyl.

- Home

- Source & Line

- Analogue Source

- My version of an Ultrasonic Record Cleaner