I couldn't tell clearly by looking but do you have any antiskate on your arm?

No Antiskate Does not seam to be a major problem.

One suggestion, if i saw it right from the pics, the internal cabling exits are 20 to 30mm further than the toneram pivot point. Get it as close you can to pivot, by doing it the cables will have the least effect on the tonearms free movement.

Thanks for the suggestion will modify arm next time I do any thing on the table. Progress has come to a screaming halt as I have not been able to find a motor that will run at a constant speed and quietly if anyone has any suggestions I would like to here them, my options here in New Zealand are very limited.

Thanks for the intrest.

Hello,

These guys here http://www.formgestalter.com/krishu/gallery/tlacoustics.htm

have a motor-battery controller combination that works beeeeautifull, much better than every known maker i tried before. Maybe you should give them a try.

Hope that helps.

Padel

These guys here http://www.formgestalter.com/krishu/gallery/tlacoustics.htm

have a motor-battery controller combination that works beeeeautifull, much better than every known maker i tried before. Maybe you should give them a try.

Hope that helps.

Padel

Hi,

Ah...Krishu is a member here.

I had no idea he's producing TTs now.

Hold on, I'll call him...

"Krishu??? Wo bist du?"

Just kidding...marvelous TT stuff isn't it?😎

Cheers,😉

Maybe you should give them a try.

Ah...Krishu is a member here.

I had no idea he's producing TTs now.

Hold on, I'll call him...

"Krishu??? Wo bist du?"

Just kidding...marvelous TT stuff isn't it?😎

Cheers,😉

Frank,

Actually it is not krishu who made this.

It is from TL Acoustic Greece. They also sell kit and parts for turntables.

Cheers

Padel

Actually it is not krishu who made this.

It is from TL Acoustic Greece. They also sell kit and parts for turntables.

Cheers

Padel

Floppy disk motor

Since I have noise problems with AC motors coupled with the GRADO prestige I tried the floppy disk motor.

I did it for my Project 1.9 , in fact I take the pulley from the original AC motor .

The floppy motor has the same speed ( what a luck!)of the project motor.

The floppy motor is crystal controlled.

For the sound: it is clearly more controlled in the pitch and of course better dinamics.

PS no more noise back from the GRADO prestige even in internal grooves.😎

Since I have noise problems with AC motors coupled with the GRADO prestige I tried the floppy disk motor.

I did it for my Project 1.9 , in fact I take the pulley from the original AC motor .

The floppy motor has the same speed ( what a luck!)of the project motor.

The floppy motor is crystal controlled.

For the sound: it is clearly more controlled in the pitch and of course better dinamics.

PS no more noise back from the GRADO prestige even in internal grooves.😎

Attachments

Outstanding!!

How did you get around the control Circuit?

Love the Pulley did you turn it yourself?

How did you get around the control Circuit?

Love the Pulley did you turn it yourself?

Hello,

The control circuit is under the motor table . Pulling this table (after the removal of the pulley) the chip circuit , the crystal and the coils appears.

To make it working it is necessary ,over the + vcc and ground, to connect a ground to the MON terminal.

This is a relatively old floppy , from the last '80 ,and I do not know if the connection pins are standard.

****************************

No I didn't turn the pulley myself , I just used the one from the PROJECT AUDIO P6.9(uncorrect "1.9" in the previous post) turntable and adapted for the new diameter motor 4millimeter.

The control circuit is under the motor table . Pulling this table (after the removal of the pulley) the chip circuit , the crystal and the coils appears.

To make it working it is necessary ,over the + vcc and ground, to connect a ground to the MON terminal.

This is a relatively old floppy , from the last '80 ,and I do not know if the connection pins are standard.

****************************

No I didn't turn the pulley myself , I just used the one from the PROJECT AUDIO P6.9(uncorrect "1.9" in the previous post) turntable and adapted for the new diameter motor 4millimeter.

much progress

Motor pod finished I blue up the floppy drive motor and went back to a Gerard AC sycrono.I also turned a twin pully for both speeds and I bought the KAB strobe disc and to my delight the speeds i am getting are with in broudcast quility the belt for the moment is cotton If anyone is using somethig else i would like to here your thoughts.

Also have started to do some work on my Phono Amp a new power supply is being tested the curcuit board came from this site http://sound.westhost.com/projects.htm#index First impressions are it is very quite.

Will post more later

Ps Dont be shy with any opions

Motor pod finished I blue up the floppy drive motor and went back to a Gerard AC sycrono.I also turned a twin pully for both speeds and I bought the KAB strobe disc and to my delight the speeds i am getting are with in broudcast quility the belt for the moment is cotton If anyone is using somethig else i would like to here your thoughts.

Also have started to do some work on my Phono Amp a new power supply is being tested the curcuit board came from this site http://sound.westhost.com/projects.htm#index First impressions are it is very quite.

Will post more later

Ps Dont be shy with any opions

Attachments

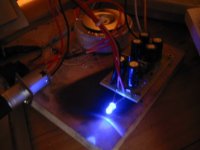

PSU finished

Finished PSU 100mm diameter aluminium 250mm long front and back plate 100mm diameter 10mm thick (pig to drill holes especialy ther square IEC power socket) all held together with 8mm threaded rod. Front face finished with Brass Acrylic window with Blue LED for Power.

Finished PSU 100mm diameter aluminium 250mm long front and back plate 100mm diameter 10mm thick (pig to drill holes especialy ther square IEC power socket) all held together with 8mm threaded rod. Front face finished with Brass Acrylic window with Blue LED for Power.

Attachments

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- My table project