Greetings everyone,

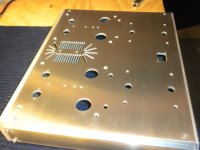

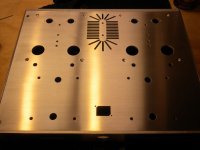

Just wanted to show you my "Red board" chassis before it gets stuffed. My plan is a separate power supply. If anyone has any questions, you can get me at rsumperl@hhk.com

Ray

Just wanted to show you my "Red board" chassis before it gets stuffed. My plan is a separate power supply. If anyone has any questions, you can get me at rsumperl@hhk.com

Ray

Attachments

-

DSCN0885.JPG398.3 KB · Views: 750

DSCN0885.JPG398.3 KB · Views: 750 -

DSCN0887.JPG343 KB · Views: 706

DSCN0887.JPG343 KB · Views: 706 -

DSCN0889.JPG313.3 KB · Views: 678

DSCN0889.JPG313.3 KB · Views: 678 -

DSCN0892.JPG365.1 KB · Views: 657

DSCN0892.JPG365.1 KB · Views: 657 -

DSCN0893.JPG529.5 KB · Views: 636

DSCN0893.JPG529.5 KB · Views: 636 -

DSCN0896.JPG384.7 KB · Views: 245

DSCN0896.JPG384.7 KB · Views: 245 -

DSCN0895.JPG459.3 KB · Views: 245

DSCN0895.JPG459.3 KB · Views: 245 -

DSCN0898.JPG365.8 KB · Views: 211

DSCN0898.JPG365.8 KB · Views: 211 -

DSCN0899.JPG345.5 KB · Views: 183

DSCN0899.JPG345.5 KB · Views: 183

Did you machine this yourself or (wisely) use someone like Front Panel Express?

This will look far better than my particle board and test lead construction...

This will look far better than my particle board and test lead construction...

Actually Stuart, I wish I had the machinery to do it, love doing that kind of stuff, must be the male power tool thing, but alas, I drew it out and sent it to a shop in Chicago.

As a side note, the most "fun" job this EE ever had (besides working in Detroit) was working at an engine rebuilder in Melbourne Florida!

As a side note, the most "fun" job this EE ever had (besides working in Detroit) was working at an engine rebuilder in Melbourne Florida!

Actually Stuart, I wish I had the machinery to do it, love doing that kind of stuff, must be the male power tool thing, but alas, I drew it out and sent it to a shop in Chicago. As a side note, the most "fun" job this EE ever had (besides working in Detroit) was working at an engine rebuilder in Melbourne Florida!

Would you be willing to share the name of the shop? I'm in Chicago and I sure would be happy to find a good one.

Thanks!

Big red board.

Looks sweet, can't wait to see it stuffed. What iron and tubes have you selected??

I went wood with the second amp. Just was able to get the wood stained and the plate buffed. Head to China tomorrow.

I received the knobs that I ordered before Christmas so I was able to finish the first one as designed. The other knobs were a little tacky.

Looks sweet, can't wait to see it stuffed. What iron and tubes have you selected??

I went wood with the second amp. Just was able to get the wood stained and the plate buffed. Head to China tomorrow.

I received the knobs that I ordered before Christmas so I was able to finish the first one as designed. The other knobs were a little tacky.

Attachments

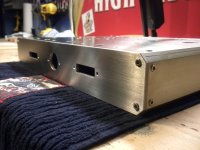

That chassis looks quite good. Is it completely custom or does somebody make that base chassis minus custom machining?

The detail that really sells it for me is what looks like tight tolerances on the beveled edges and the fact that the panels look nice and thick.

The detail that really sells it for me is what looks like tight tolerances on the beveled edges and the fact that the panels look nice and thick.

Actually Stuart, I wish I had the machinery to do it, love doing that kind of stuff, must be the male power tool thing, but alas, I drew it out and sent it to a shop in Chicago.

Just wondering, how much did it cost you to have them do the machining for you?

ok, well here is the sticker shock, since mine was "special" I paid $350, he believes he can do the "stock or near stock" one for $300. I am waiting for a call back as to whether they can bring the price down further.

Ray

Ray

I'd be curious what he'd charge if he were doing 5-10 of these...? Setup is usually the lion's share, and amortization is a wonderful thing.

Stuart, that was one of the questions I asked. Hopefully he will get back with me by tomorrow evening.

Looks great.. I am itching to build my first tube amp. Is this for PCB or point to point? Do you have the schematic? thanks.

Sorry about the delayed response fellas. I've been trying to find this in the forums for a while.

I built this chassis for Ray. If anyone is interested in this, read my posts to follow and I will post detailed pics of the chassis frame. Trust me it's a lot cooler than it looks in previous pics.

And yes, I will build custom, plain, or ???

I built this chassis for Ray. If anyone is interested in this, read my posts to follow and I will post detailed pics of the chassis frame. Trust me it's a lot cooler than it looks in previous pics.

And yes, I will build custom, plain, or ???

Would you be willing to share the name of the shop? I'm in Chicago and I sure would be happy to find a good one.

Thanks!

Shane,

Our shop is American CNC Machine Inc. We are located in Addison. We are a full service job shop with design, prototyping, and production capabilities. The chassis is a pet project of mine. Give me a call if there's anything you need. 630-669-4304

Bob

The chassis

So here's the low down on this chassis.

In the pics you will notice more than a few features that set it apart from your standard thin sheet metal boxes.

First, all panels are removable.

The top and rear are attached with two small welds which means you can remove all of your components from the chassis, work on them, and reinstall easily.

Removing either side panel exposes the chassis frame, which is common to both sides. There are also several tapped holes in each frame that can be used for wire holders or a buss bar or barrier strips (actually the spacing top to bottom is designed for a 4 position barrier strip available at any "Radio Shack")allowing you to easily change output taps or set bias or what ever you want to use them for.

All panels are made from 3/16" Alum except for the front which is 3/8". This makes the chassis, as a whole, very solid and as you would expect minimally resonant, especially compared to thin sheet metal.

This design is also scaleable as you can see in some of the last pics which are showing my Pre and PS.

The chassis's I have built to date have been built by hand for the most part. I found for single units it's the only way to control the quality.

I could do a production run if someone wanted, any more than 4 could be done on our CNC mills which would reduce the price. Obviously more units per order means less cost per unit.

Anyone interested can call me at 630-669-4304.

So here's the low down on this chassis.

In the pics you will notice more than a few features that set it apart from your standard thin sheet metal boxes.

First, all panels are removable.

The top and rear are attached with two small welds which means you can remove all of your components from the chassis, work on them, and reinstall easily.

Removing either side panel exposes the chassis frame, which is common to both sides. There are also several tapped holes in each frame that can be used for wire holders or a buss bar or barrier strips (actually the spacing top to bottom is designed for a 4 position barrier strip available at any "Radio Shack")allowing you to easily change output taps or set bias or what ever you want to use them for.

All panels are made from 3/16" Alum except for the front which is 3/8". This makes the chassis, as a whole, very solid and as you would expect minimally resonant, especially compared to thin sheet metal.

This design is also scaleable as you can see in some of the last pics which are showing my Pre and PS.

The chassis's I have built to date have been built by hand for the most part. I found for single units it's the only way to control the quality.

I could do a production run if someone wanted, any more than 4 could be done on our CNC mills which would reduce the price. Obviously more units per order means less cost per unit.

Anyone interested can call me at 630-669-4304.

Attachments

-

DSCN0915.JPG160.1 KB · Views: 177

DSCN0915.JPG160.1 KB · Views: 177 -

DSCN0916.JPG194.1 KB · Views: 160

DSCN0916.JPG194.1 KB · Views: 160 -

DSCN0917.JPG198.8 KB · Views: 155

DSCN0917.JPG198.8 KB · Views: 155 -

DSCN0920.JPG96.7 KB · Views: 106

DSCN0920.JPG96.7 KB · Views: 106 -

DSCN0919.JPG167 KB · Views: 89

DSCN0919.JPG167 KB · Views: 89 -

DSCN0918.JPG219.4 KB · Views: 155

DSCN0918.JPG219.4 KB · Views: 155 -

DSCN0921.JPG173.6 KB · Views: 101

DSCN0921.JPG173.6 KB · Views: 101 -

DSCN0922.JPG145.5 KB · Views: 122

DSCN0922.JPG145.5 KB · Views: 122 -

DSCN0924.JPG162.1 KB · Views: 131

DSCN0924.JPG162.1 KB · Views: 131 -

DSCN0925.JPG138.6 KB · Views: 127

DSCN0925.JPG138.6 KB · Views: 127

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- My "Red board" chassis