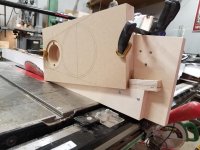

Cut a wedge so the bevel line is parallel to the horizontal plane and attach a small stop block so the baffle does not want to ride backwards during the cut.

Attach wedge to a ply carrier board and make the cut.

Remove and flip wedge, cut other side.

Attach wedge to a ply carrier board and make the cut.

Remove and flip wedge, cut other side.

Attachments

-

78977045_10156902736382741_4054949005782679552_n.jpg63 KB · Views: 363

78977045_10156902736382741_4054949005782679552_n.jpg63 KB · Views: 363 -

79471108_10156902736412741_6492856242099191808_n.jpg61.7 KB · Views: 360

79471108_10156902736412741_6492856242099191808_n.jpg61.7 KB · Views: 360 -

76765571_10156902736447741_4683298645263515648_n.jpg73.9 KB · Views: 372

76765571_10156902736447741_4683298645263515648_n.jpg73.9 KB · Views: 372 -

78579105_10156902736502741_7282857004513624064_n.jpg66.4 KB · Views: 359

78579105_10156902736502741_7282857004513624064_n.jpg66.4 KB · Views: 359 -

78931204_10156902736547741_5100627758283751424_n.jpg71.2 KB · Views: 366

78931204_10156902736547741_5100627758283751424_n.jpg71.2 KB · Views: 366 -

79137274_10156902736587741_452774262638379008_n.jpg81.9 KB · Views: 244

79137274_10156902736587741_452774262638379008_n.jpg81.9 KB · Views: 244 -

78965114_10156902736647741_8444502901958639616_n.jpg69.4 KB · Views: 242

78965114_10156902736647741_8444502901958639616_n.jpg69.4 KB · Views: 242 -

78759232_10156902736702741_5694368250645708800_n.jpg76.5 KB · Views: 219

78759232_10156902736702741_5694368250645708800_n.jpg76.5 KB · Views: 219 -

79628137_10156902736787741_3529851294925717504_n.jpg67.4 KB · Views: 217

79628137_10156902736787741_3529851294925717504_n.jpg67.4 KB · Views: 217 -

79122679_10156902736842741_985377106722553856_n.jpg62.4 KB · Views: 228

79122679_10156902736842741_985377106722553856_n.jpg62.4 KB · Views: 228

Good idea. I've looked at your pics, and unless I'm missing something you could make one improvement for safety. Why not make a guide which rides on the fence, with a face on the side opposite the blade (basically an inverted 'U'). Your cuts would be the same, but you'll eliminate having to feed while ensuring you're panels are against the fence.