Hi there!

Very nice job you did! Extremely elegant!

Anyone knows if there are any shop here in Canada that sells cases like that?

Jordan

Very nice job you did! Extremely elegant!

Anyone knows if there are any shop here in Canada that sells cases like that?

Jordan

Hi Peppe.

Your amp looks good, but if the toroid is mounted with a iron-bar/bolt you might run into some problems with grounding and possibly shorting the Xformer.

I general I think it's bad practice to use the toroid-bolt for anything else than securing the toroid. I can't see the details on your amp, and I apologize if I'm mistaken about the grounding scheme.

Regards TroelsM

Your amp looks good, but if the toroid is mounted with a iron-bar/bolt you might run into some problems with grounding and possibly shorting the Xformer.

I general I think it's bad practice to use the toroid-bolt for anything else than securing the toroid. I can't see the details on your amp, and I apologize if I'm mistaken about the grounding scheme.

Regards TroelsM

Jordan Roy said:Hi there!

Very nice job you did! Extremely elegant!

Anyone knows if there are any shop here in Canada that sells cases like that?

Jordan

Thank you Jordan, 🙂

the Hi-Fi2000 seem have not a retailer outside Italy.

🙁

Cheers

Peppe

TroelsM said:Hi Peppe.

Your amp looks good, but if the toroid is mounted with a iron-bar/bolt you might run into some problems with grounding and possibly shorting the Xformer.

I general I think it's bad practice to use the toroid-bolt for anything else than securing the toroid. I can't see the details on your amp, and I apologize if I'm mistaken about the grounding scheme.

Regards TroelsM

Hi Troels,

the toroid is mounted with a steel-bar 12/10 mm thin and the bolt is insulated from the bar with a plastic cylinder.

When I did it was the easy way for me and I thought if something wrong it is easy to change and use another material.

I am using the amp in the weekend and all seem OK, what kind of problems I must consider? Noise in the speaker or hum from the toroid?

I will try to do a grounding scheme if necessary.

Anyway Thank for yours considerations, I am just a newbie.

Regards

Peppe

Hi Peppe.

If the bolt (that's holding the toroid) is connected to the chassis and the plate one top of the toroid AND the plate is connected to GND/chassis in any other way you might have a problem. Then you have a shorted turn on the Xformer and it will heat up.

It's a bit hard to explain. Maybe someone with English as native language can a better job at it?

Regards TroelsM

If the bolt (that's holding the toroid) is connected to the chassis and the plate one top of the toroid AND the plate is connected to GND/chassis in any other way you might have a problem. Then you have a shorted turn on the Xformer and it will heat up.

It's a bit hard to explain. Maybe someone with English as native language can a better job at it?

Regards TroelsM

Hi Gewa.

That's about right. But the loop could also be completed through the grounded connections to another cabinet... That would send massive currents through the GND-wires and connectors...

All in all you should never connect anything to/on the bolt holding the toroid (unless it's a fiberglass/nylon-rod..).

Regards TroelsM

That's about right. But the loop could also be completed through the grounded connections to another cabinet... That would send massive currents through the GND-wires and connectors...

All in all you should never connect anything to/on the bolt holding the toroid (unless it's a fiberglass/nylon-rod..).

Regards TroelsM

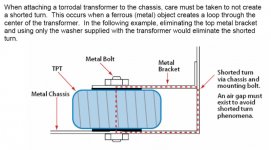

GeWa said:Peppe

This is a piece taken from BrianGT's manual (hope he doesn't mind).

Maybe you will understand better what TroelsM is trying to say.

Regards

Thank You GeWa,

very useful image, now it's more clear.

TroelsM said:

That's about right. But the loop could also be completed through the grounded connections to another cabinet...

You right TroelsM!

I think I formed a ground loop connetting the metal bracket to the case! 🙁

No problem at all, DIY is the best way to learn about! 😉

It will be easy to resolve the problem, I will use the hole (not visible in the picture) down the PCB not to screw the psu groud but simple to make the cable to pass and to connect it to the bottom of the case. Unfortunately I will work only in the weekend!

BTW, I have a problem but what is the consequence? 😕 It seem all work fine...

When I will fix the problem, what I am looking for to check if the problem is removed?

Thanks again

Peppe

Hi Peppe.

I'm not sure I understand what you are saying, but the simple solution to the problem is to hold the plate/Psu with something else than the toroid-bolt.

If you have created a shorted turn, your xformer will probably heat up, - and maybe hum.

Regards TroelsM

I'm not sure I understand what you are saying, but the simple solution to the problem is to hold the plate/Psu with something else than the toroid-bolt.

If you have created a shorted turn, your xformer will probably heat up, - and maybe hum.

Regards TroelsM

TroelsM said:Hi Peppe.

I'm not sure I understand what you are saying, but the simple solution to the problem is to hold the plate/Psu with something else than the toroid-bolt.

If you have created a shorted turn, your xformer will probably heat up, - and maybe hum.

Regards TroelsM

Hi,

yes, it is difficult to explain in word.... and to make a picture too.

The temp of the toroid after 3 hours is very low at finger touch.

The hum is very low too with the Aleph on the wood table, it increase if I put the amp on a glass console but don't become a problem.

At the end... I understood: steel-plate FAR from the toroid-bolt!

I got all the week to look for a solution.... and study ground loops and correlated problems. 😉

Cheers

Peppe

Member

Joined 2002

Peppe,

I think if you spaced out them fet's more it might help disapate the heat more. Maybe adding some coper bar..

I have not seen many people put 6 fets onto a small heat sink.

I use 2 fets from my class a Mini Aleph on a heat sink that is 5.5" x 12" x 1.5" and it gets pretty warm..

I think if you spaced out them fet's more it might help disapate the heat more. Maybe adding some coper bar..

I have not seen many people put 6 fets onto a small heat sink.

I use 2 fets from my class a Mini Aleph on a heat sink that is 5.5" x 12" x 1.5" and it gets pretty warm..

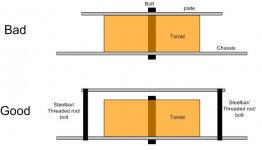

TroelsM said:Hi Peppe.

Glad that you get the point. Here's a sketch of a better solution. Its stronger and should avoid problems.

Regards TroelsM

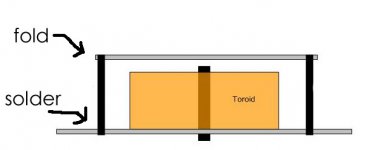

Hi TroelsM,

I have a friend that work the steel, inspired from your draw I am thinking to realize a fold-solder structure do give more rigidity at the bottom of the case (because of the toroid weight) and resolve finally the loop problem.

look at the picture.

Cheers

Peppe

Attachments

jleaman said:Peppe,

I think if you spaced out them fet's more it might help disapate the heat more. Maybe adding some coper bar..

I have not seen many people put 6 fets onto a small heat sink.

I use 2 fets from my class a Mini Aleph on a heat sink that is 5.5" x 12" x 1.5" and it gets pretty warm..

Hi,

what you mean "spaced out fets", separate all 12 fets each other or only separate the 2 side of pcb from the main board?

When I bought the case I didn't know much about the heat dissipation (and other things too). Now I am planning to use the biggest case I found (each heatsink 400x200x40 mm) for an Aleph 5. When I will do I could reduce the Aleph30 to a miniAleph (?)....

So the question is I must be in hurry if I use thise Aleph as it is for a year or so? Can I burn the mosfets?! It was only school ship.

What temp rise your heatsinks?

Regards

Peppe

Peppe,

leave it like it is, the output device spacing and placement on the heatsinks is not so bad.

They way you have placed the PCBs you bought on the heatsinks is quite good.

I can show you plenty of pictures from professional products that weren't so well done for cooling, even some class A designs.

A suggestion for additional cooling would be to find a nice heavy piece of stone and place the amplifier thermally coupled on top of it. Marble or granite looks the nicest, but even concrete works.

(not my brainwave, stole the idea from an audio company in Germany long time ago, Brinkmann amplifiers => www.brinkmann-usa.com/monoamplifiers.php These mono amps cost around 12000 Euros nowadays, so you won't have to feel ashamed)

leave it like it is, the output device spacing and placement on the heatsinks is not so bad.

They way you have placed the PCBs you bought on the heatsinks is quite good.

I can show you plenty of pictures from professional products that weren't so well done for cooling, even some class A designs.

A suggestion for additional cooling would be to find a nice heavy piece of stone and place the amplifier thermally coupled on top of it. Marble or granite looks the nicest, but even concrete works.

(not my brainwave, stole the idea from an audio company in Germany long time ago, Brinkmann amplifiers => www.brinkmann-usa.com/monoamplifiers.php These mono amps cost around 12000 Euros nowadays, so you won't have to feel ashamed)

jacco vermeulen said:Peppe,

leave it like it is, the output device spacing and placement on the heatsinks is not so bad.

They way you have placed the PCBs you bought on the heatsinks is quite good.

I can show you plenty of pictures from professional products that weren't so well done for cooling, even some class A designs.

A suggestion for addtional cooling would be to find a nice heavy piece of stone and place the amplifier thermally coupled on top of it. Marble or granite looks the nicest, but even concrete works.

(not my brainwave, stole the idea from an audio company in Germany long time ago, Brinkmann amplifiers => www.brinkmann-usa.com/monoamplifiers.php )

Thanks Jacco,

when I did the work I thought how did it in the easiest way, at the end I am very happy to the result in the look too!

Of course I was inspired from others works, here in the forum and professional too. Looking at the pictures of T-50, seem the IGBTs was mounted very close! But I absolutely dont know how much dissipate each component...

Great thing the marble! I have no problem at all to find and working marble, my town (I study only in Naples) is very famous for working stone!

Just this weekend I will retire the stands for my ls 3/5a in a white italian marble..... 😀

It is possible to calculate how much the marble help to dissipate?

Maybe the next project I could do some experiment....

Regards

Peppe

Attachments

Peppe said:white italian marble

I know,

even much, much cheaper than buying it here.

An Italian collegue i had is from Napoli too, he brought white marble back with him from a family visiting holiday. Enough to put marble on every floor in his home, bathrooms and kitchen included.

A white Italian marble plate under your amplifier would look pretty nice, i think.

Calculating the size isn't that easy as the plate is under the amp, and it also depends on how it is placed under the amplifier.

Best way would be to put the marble plate on feet.

And with some clearance between the stone and the amplifier, but thermally coupling the amplifier feet to the stone.

That way there is air circulation around the marble, hot air can enter the amplifier from the holes in the bottom and move out through the holes on top.

This chimney effect is hard to calculate, but can halve the effective thermal cooling factor of such a marble plate.

The limiting factor is not the heatsink material (whether aluminium or marble) but the thermal transfer factor of air.(0.025 W/M*C)

Means, just as with an aluminium heatsink, it is best to have a marble plate exposed to as much air as possible and enable airflow.

You only need a couple of digits to drop the temperature of your A-30 to 50 Cs or below.

So, if a stone would take care of 10 % of the total dissipation you'd hit that mark.

10 % of 0.165 C/W (0.33/2) is only 1.65 C/W for the marble plate.

About an inch thick, like the Brinkmanns, would probably be enough and look good.

If you don't mind the look of a 2 inch high marble socket, the higher the plate the better. Half an inch clearance between amplifer and marble plate does more good than thicker marble.

Ciao.

Very nice work, Peppe.

How does it sound?

Wish I can buy cases like that here in the United States but nobody here makes cases with heatsinks on the sides (that I know of).

Still waiting for my ATI Research cases from Thailand.....

How does it sound?

Wish I can buy cases like that here in the United States but nobody here makes cases with heatsinks on the sides (that I know of).

Still waiting for my ATI Research cases from Thailand.....

Arius said:Very nice work, Peppe.

How does it sound?

Wish I can buy cases like that here in the United States but nobody here makes cases with heatsinks on the sides (that I know of).

Still waiting for my ATI Research cases from Thailand.....

Thank you Arius,

It is not easy to say in word how an amplifer sounds, the first thing I noted was the tremendous 3D sound! When I tested the first channel the sound seemed to come from a deeper room, when I finally tested both channels was the first time I heard a player (an instrument) to come perfectly from the center of the scene! How I said the instrument seem very present and detailed, the bass is not deep like the Threshold T50 but MY Aleph30 sound very refined! (sorry my raw language 🙂)

Fortunately in Italy HiFi2000 make those cases, they could be better if the heat-sink was larger than 40mm!

When Your ATI arrived post your impression and tell us about the costs...

What project are you planing?

Regards

Peppe

TroelsM said:

Here's a sketch of a better solution.

At the end I did exactly how your sketch show...

Easy and definitive!

I did some experiment shorting the toroid-bolt to ground. When the amp is on wood or marble table the hum don't increase but when the amp is on the glass console the difference is udible.

Before the hum was not a problem but this experiment dimostrate that there was a problem!

Fixed this seem I can finally enjoy my Aleph.... any other suggestion are welcomed!

Thank you TroelsM

Attachments

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- My first time, Aleph 30 DONE!