Depends on impedance

Low impedance, bigger cap

High impedance, smaller cap

Try 4.7 uf, or smaller

Small ribbons should be crossed relatively high, compared to dome tweeters

They are best used as supertweeter combined with a widerange driver

Low impedance, bigger cap

High impedance, smaller cap

Try 4.7 uf, or smaller

Small ribbons should be crossed relatively high, compared to dome tweeters

They are best used as supertweeter combined with a widerange driver

I have a question.

The blues are north facing the ribbon and greens are south. Is that how they are.

I cant help but think the tensioned strings on a frame of varying thickness and tension - like a guitar ... will make for a beautiful guitar like tones.

Now are the aluminum strips also the same way for magnet arrangement ?

Cool.

Srinath.

The blues are north facing the ribbon and greens are south. Is that how they are.

I cant help but think the tensioned strings on a frame of varying thickness and tension - like a guitar ... will make for a beautiful guitar like tones.

Now are the aluminum strips also the same way for magnet arrangement ?

Cool.

Srinath.

Ok, I think I've taken this project about as far as I can without actually buying things.

Here is the current ribbon.

And now I am proud to present: My first planar speaker!!! The frame is a tin that came with a set of CD's. The same magnetix magnets stuck to the bottom of the tin. Slightly overlapping scotch tape for the film and aluminum foil for the coils. It is quite a bit louder than the ribbon speaker, but the ribbon sounds better.

Here is the current ribbon.

And now I am proud to present: My first planar speaker!!! The frame is a tin that came with a set of CD's. The same magnetix magnets stuck to the bottom of the tin. Slightly overlapping scotch tape for the film and aluminum foil for the coils. It is quite a bit louder than the ribbon speaker, but the ribbon sounds better.

Attachments

I've been playing more with the planar speakers and have a few questions. To bring the resistance up I'd still be looking at custom winding a torrid right? Do I need any capacitors? Is volume and clarity directly affected by magnet strength?

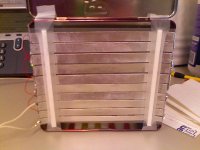

Here is a picture of my latest.

The frame is foam board. The magnets are the same as before. The effective area of the film is 5X24cm. They sound pretty good, much better than the little cambridge soundworks cubes I was using. They are very power hungry. The cheap amp I am using starts breaking up before I get to what I would consider normal listening levels. Plenty loud for my open office area though.

Here is a picture of my latest.

The frame is foam board. The magnets are the same as before. The effective area of the film is 5X24cm. They sound pretty good, much better than the little cambridge soundworks cubes I was using. They are very power hungry. The cheap amp I am using starts breaking up before I get to what I would consider normal listening levels. Plenty loud for my open office area though.

Attachments

Making ribbons like that...Is nor very hard.....

1 get 150x10x10neo magnets..

2.Frame them in a U shaped iron...I had one bent with eliptical wents in rear section..

3 make the membran by glueing Alu strips on a thin carrier..(in Denmak we can buy 5 um alu and 12 um polyester foil.. Use thinned coantact glue to bond them..

4 corrugate the membrane by folding it hard in small sharp bends..This stiffens the transvers of the menbran and prevents it from sideways breakup..

5play music..

This concept can if membrane is app 125 mm long and has 8 2.2 mm ribbons placed on a 20mm polyesterfilm reach a sensetivity of app 92-94 dB and have app. 6 ohm impedance..

Good luck

1 get 150x10x10neo magnets..

2.Frame them in a U shaped iron...I had one bent with eliptical wents in rear section..

3 make the membran by glueing Alu strips on a thin carrier..(in Denmak we can buy 5 um alu and 12 um polyester foil.. Use thinned coantact glue to bond them..

4 corrugate the membrane by folding it hard in small sharp bends..This stiffens the transvers of the menbran and prevents it from sideways breakup..

5play music..

This concept can if membrane is app 125 mm long and has 8 2.2 mm ribbons placed on a 20mm polyesterfilm reach a sensetivity of app 92-94 dB and have app. 6 ohm impedance..

Good luck

Are those measurements correct? mm? That sounds very small compared to the planar projects I see around here. Or are you talking about a ribbon speaker?

Last edited:

The back sides if the magnets have magnetic lines of force too that try to connect to their counterparts which are on the back sides of the opposite pole. Connecting those via steel takes the reverse lines of force out of the picture. Someone told me 1-2 set of magnets can be reversed to acheive the same effect if I did like I was planning. Just put a set of wood posts with a groove holding the diaphragm, and the magnets just stuck in a second row of grooves straddling the diaphragm groove. Of course wood cant transmit magnetism, and I will have a ton of reverse directional magnetic lines of force. Of course it will look cool, just magnets and decorative wood in front of and behind it.

Cool.

Srinath.

Cool.

Srinath.

Also, the magnets have to be stuck to iron? Why is that?

Another reason

If its a narrow genuine ribbon its difficult to get very strong magnets close enough

And you get less diffraction from the magnet gap

I hope to have one ready soon

Attachments

The back sides if the magnets have magnetic lines of force too that try to connect to their counterparts which are on the back sides of the opposite pole.

Connecting those via steel takes the reverse lines of force out of the picture.

The back pole iron is to direct and control the back magnetic field, instead of the wide field in air

A magnet field loose strength in air

Through the iron the field gets stronger

The front pole iron also deals with the fact that a bigger ribbons mostly involves multiple magnets

Through the iron pole the magnet field gets more homogene

Putting a small screwdriver into a magnet field tells a lot

Its very easy to "feel" where the field is strong

Just dont use that screwdriver on electronics

with the roll you created a nice low pass filter 🙂 so the frequency you would like to produce (high) are not going to the ribbon

although the impedance is ofcourse verry low so dont know where its start falling off with 6dB

although the impedance is ofcourse verry low so dont know where its start falling off with 6dB

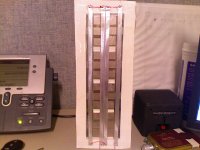

My latest set,

Same foam from before

I picked up some 50 X 13 X 3mm neodymium magnets

The coils are aluminum foil, 7mm wide.

These are by far the best sounding and most efficient pair I have built yet.

Same foam from before

I picked up some 50 X 13 X 3mm neodymium magnets

The coils are aluminum foil, 7mm wide.

These are by far the best sounding and most efficient pair I have built yet.

Attachments

Last edited:

Help please:

The speakers pictured above have a resistance of about 1Ohm. How would i go about making them 4 Ohm? I tried making a toroid transformer, but got kind of lost. I ended up making an attenuator/low pass filter...😕

The speakers pictured above have a resistance of about 1Ohm. How would i go about making them 4 Ohm? I tried making a toroid transformer, but got kind of lost. I ended up making an attenuator/low pass filter...😕

Cut each aluminum strip in half length-wise to make strips 3.5mm wide and connect them all in series.The speakers pictured above have a resistance of about 1Ohm. How would i go about making them 4 Ohm?

Double the length and half the width gives four times the resistance.

Ok, here is my latest attempt. The panel resonated a lot so I added a strip of felt between the magnets and panel. Seemed to help. This one sounds hollow as compared to the last one.. On a good note it is 3Ohm, so that is a step in the right direction.

Attachments

Ehh, about magnets

Well, it depends on type of magnitising

But the most common types are magnitised through the thickness

Which means you have N and S on the flat surface

Its easy to find the orientation of poles through turning around two magnets close to each other

Mark each magnet carefully

Placing magnets the wrong way happens all too easy, even with experience

Well, it depends on type of magnitising

But the most common types are magnitised through the thickness

Which means you have N and S on the flat surface

Its easy to find the orientation of poles through turning around two magnets close to each other

Mark each magnet carefully

Placing magnets the wrong way happens all too easy, even with experience

The magnets are between the leads. The polarity is through the thickness. And your right, the direction of the current does present one single lead, the purpose is to utilize the collective principle as shown here Woofer, membrane ribbon loudpseaker conductor design. Only instead of two runs between the magnets I used four to increase resistance.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- My first ribbon speaker