Hi everyone

I'm Murasame Yui

My full time job is high power LEV/EV battery PCB designer

Also DIY is my hobby.

So i design a battery wireless amplifier myself.

All the circuit and mechanical and PCB are design by me.

I only build one and will never mass production.

because it's too expensive.

It's spent me over 10,000 USD and 3 month.

(sorry for typing mistake, It's 10,000 USD not 100,000)

USB to Headphone

USB=>Adum3160=>CM6631A=>74HC32=>

AK4399=>MUSES72320=>AD815=>Headphone

BT 5.0 to Headphone

CSR8675=>CS8414=>74HC32=>

AK4399=>MUSES72320=>AD815=>Headphone

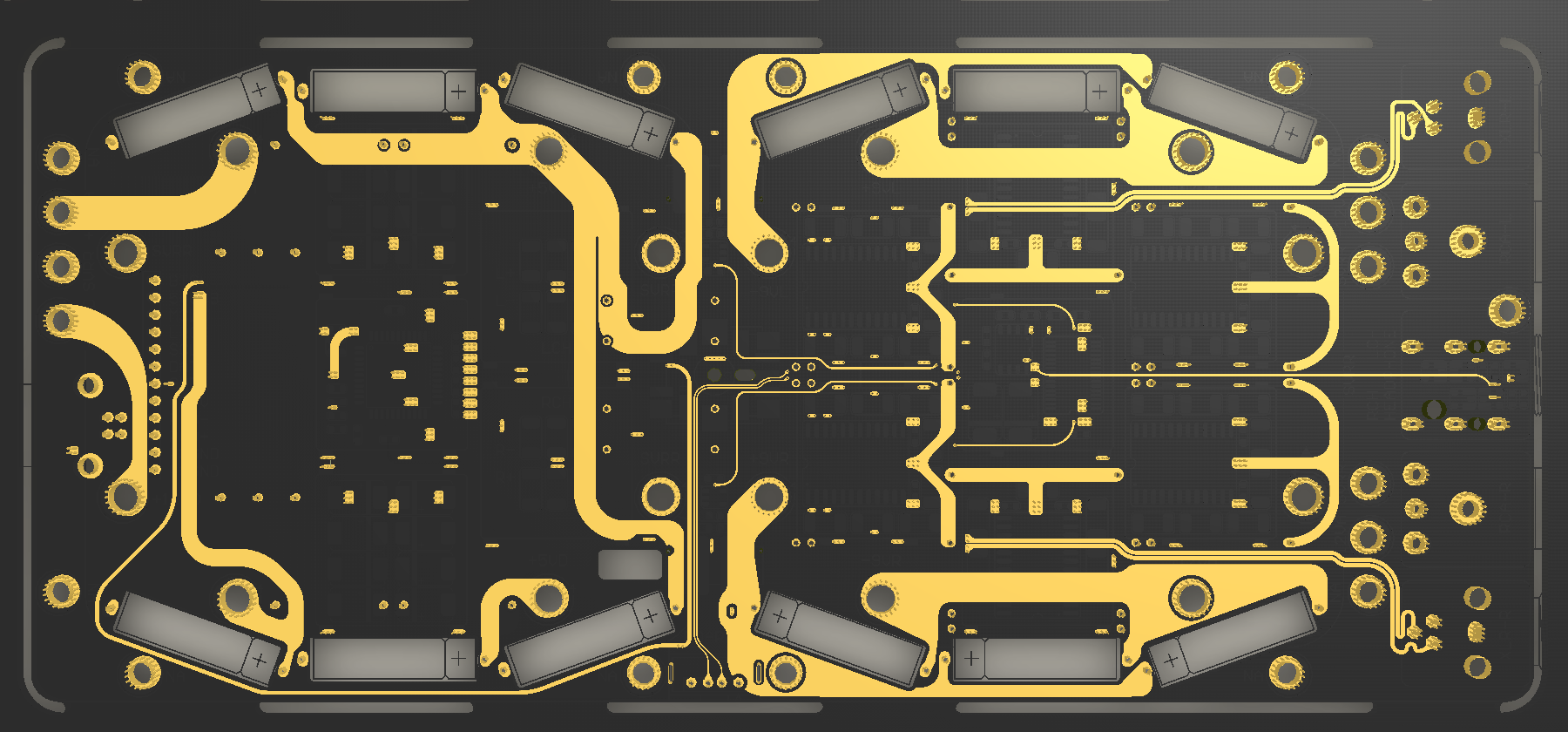

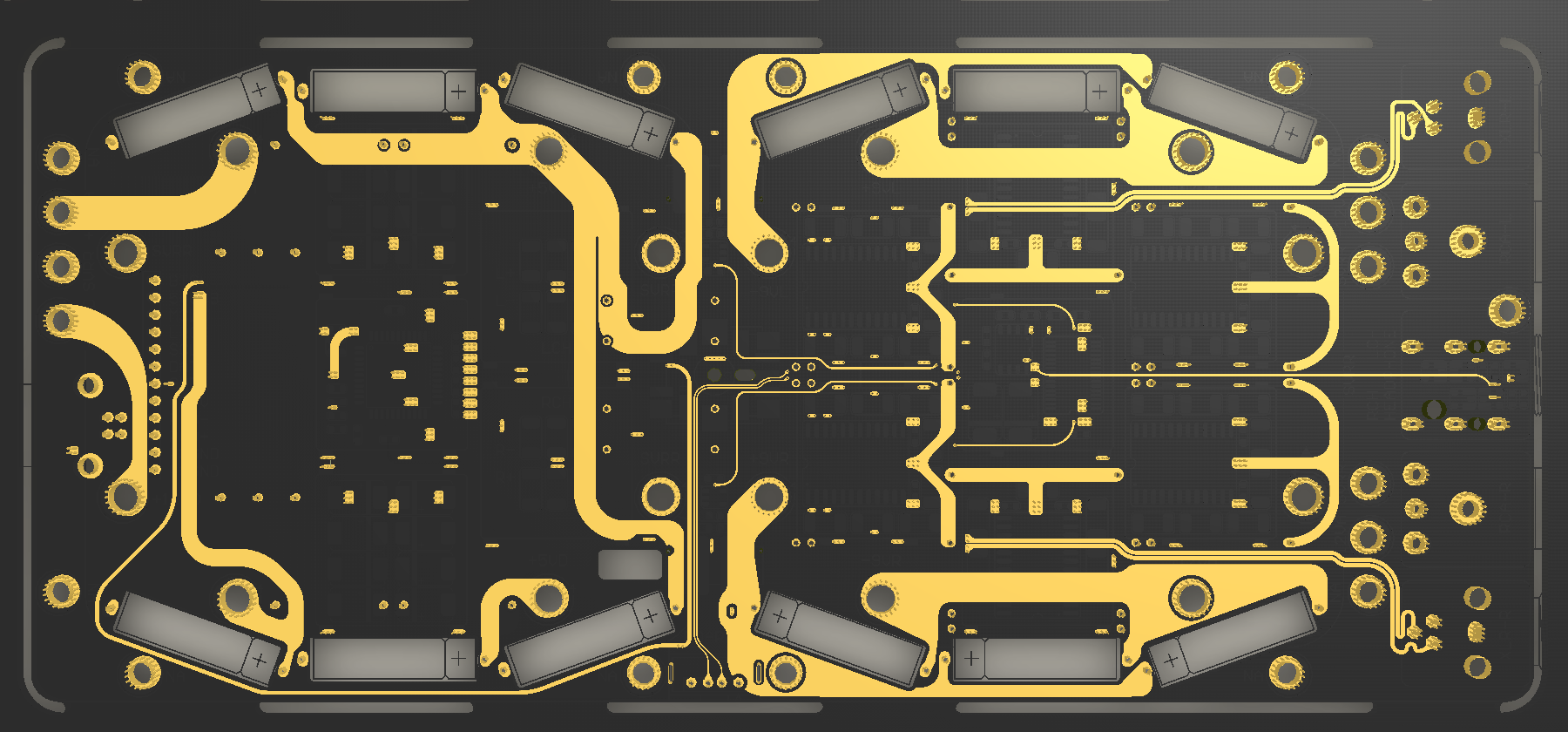

Battery capacity Li-po 4000mAh 4S6P = 355Wh

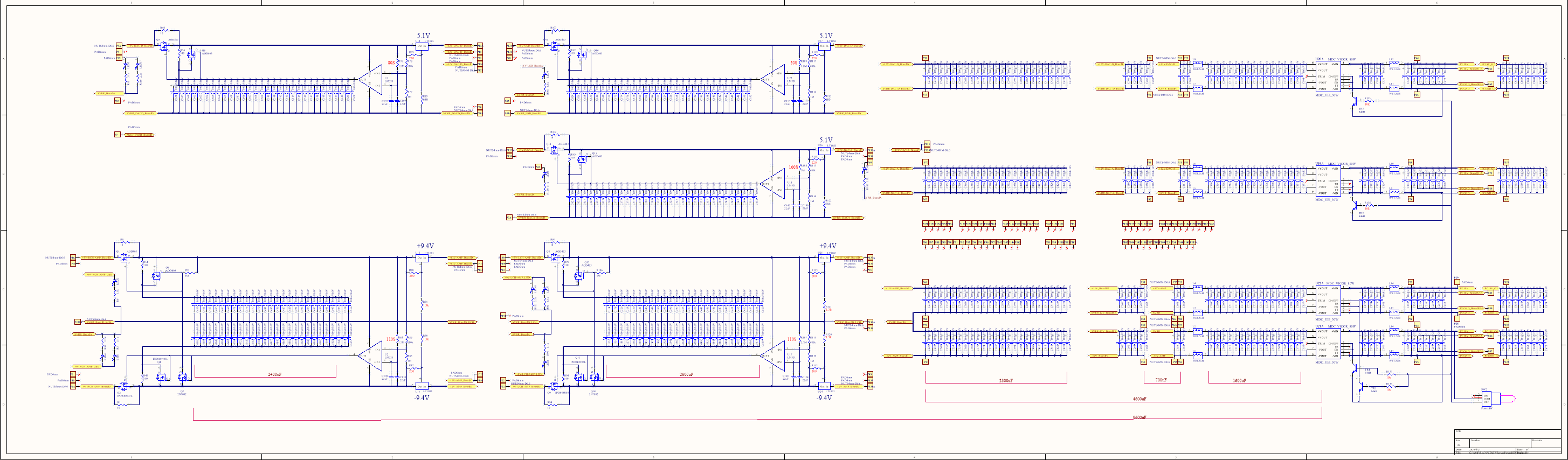

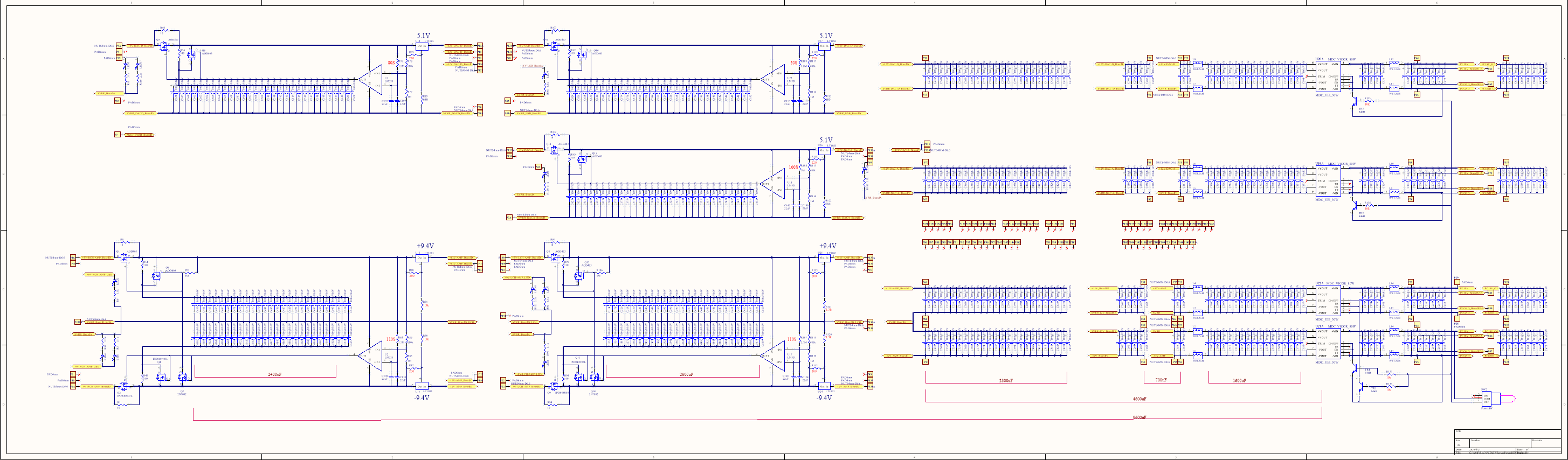

Amplifier

Isolated power supply

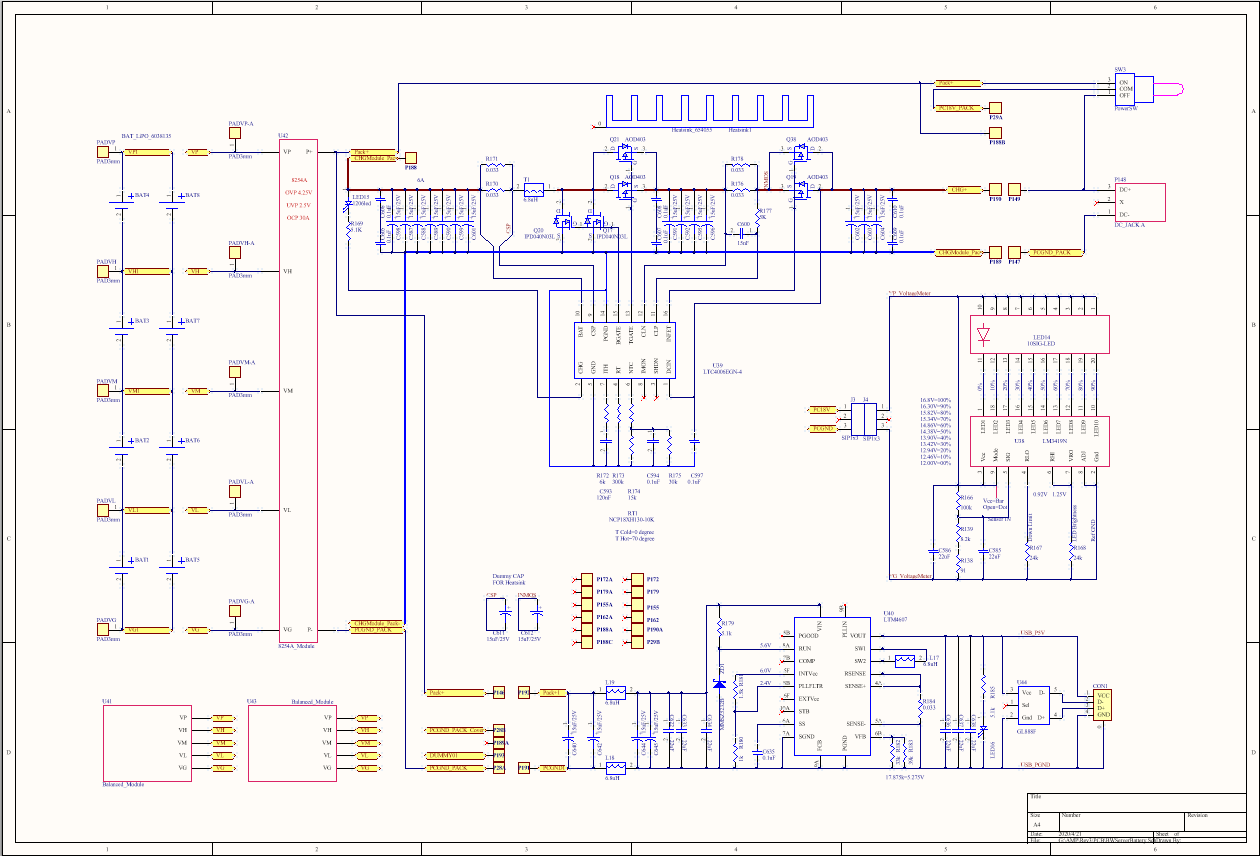

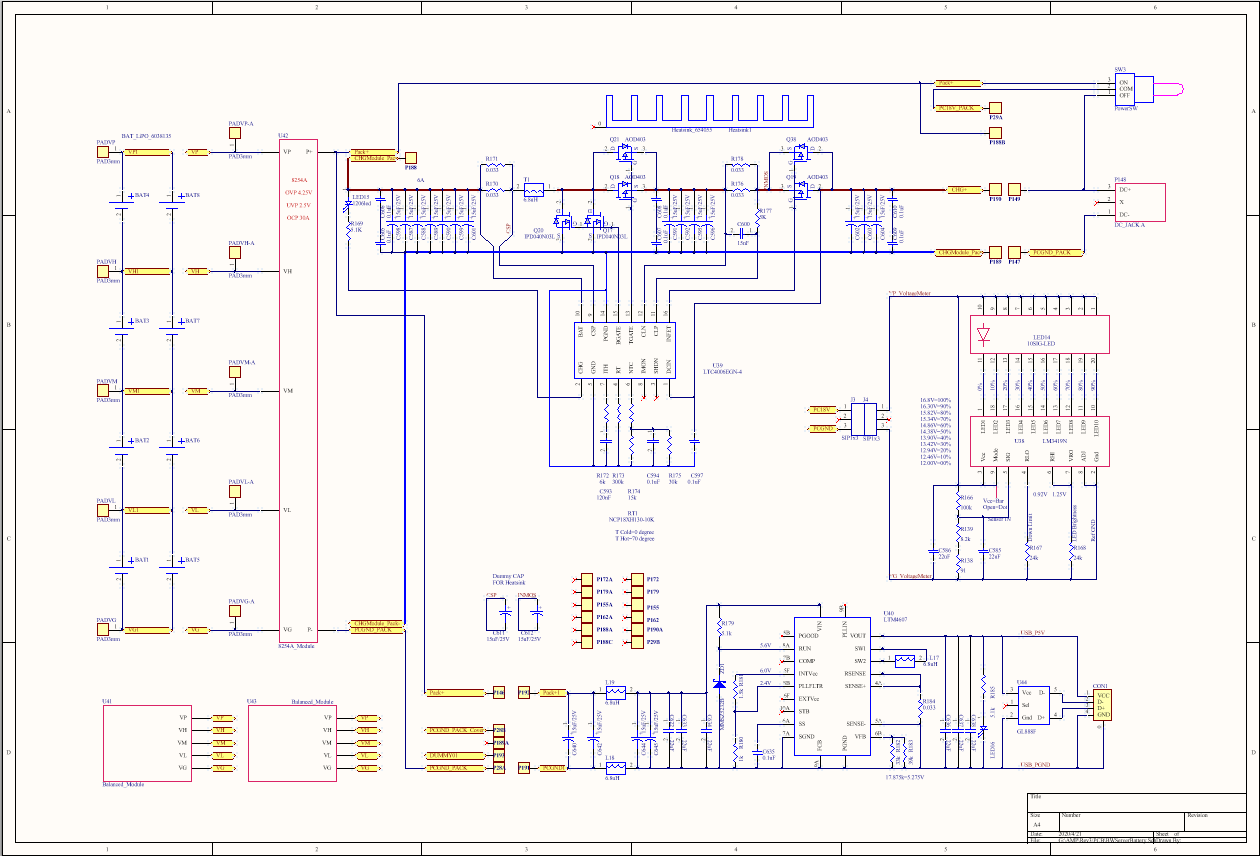

Battery & Charger

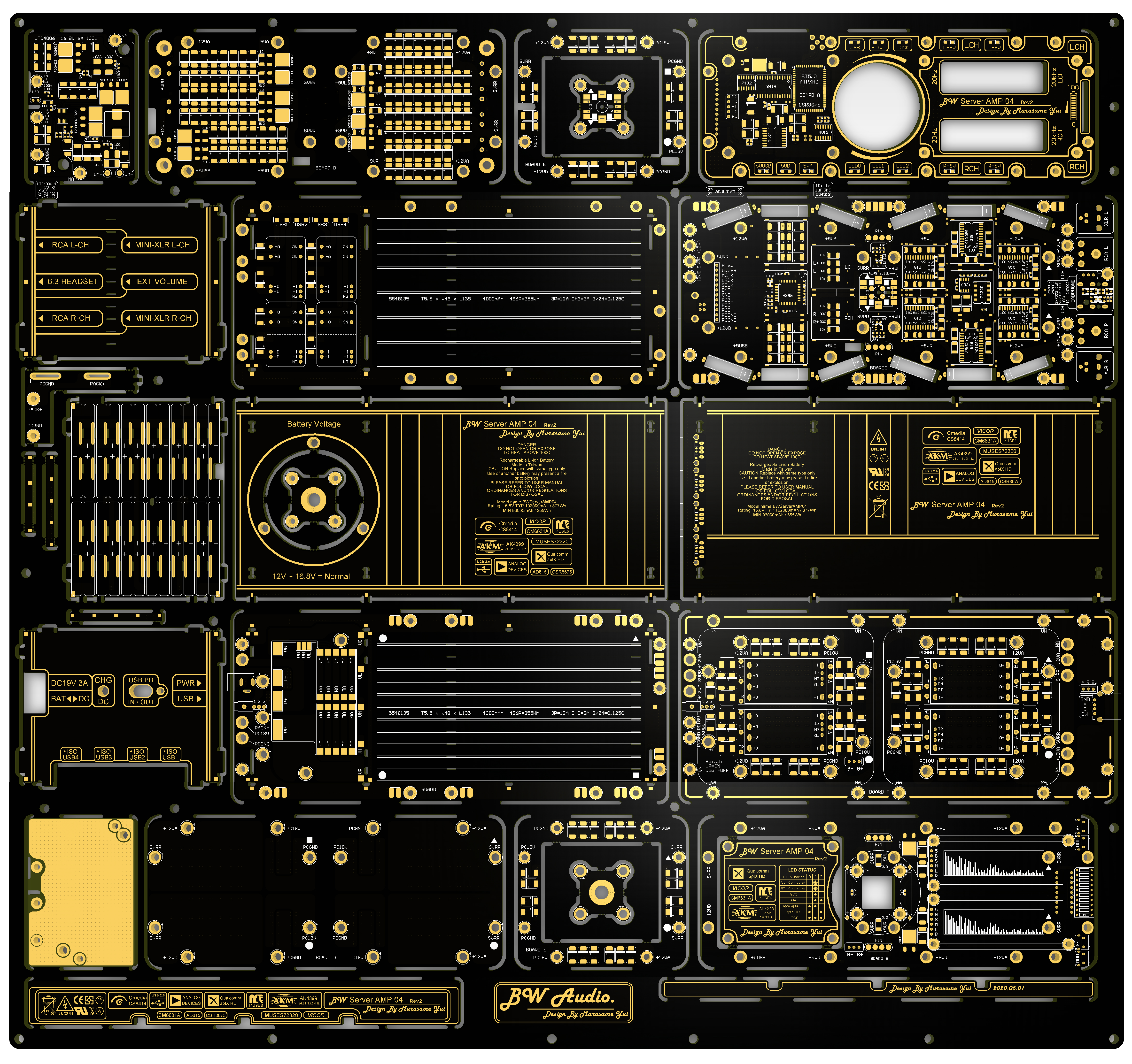

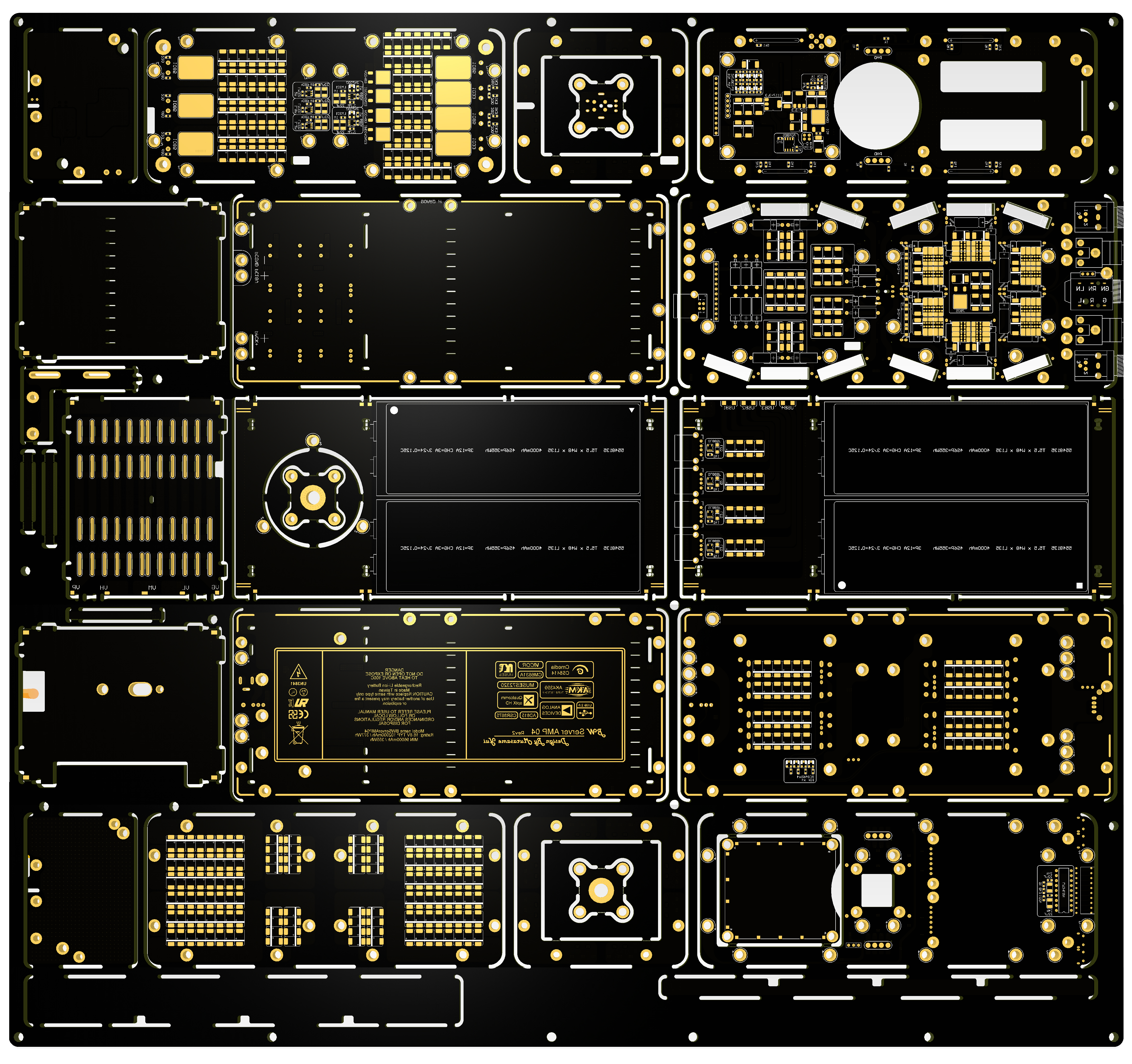

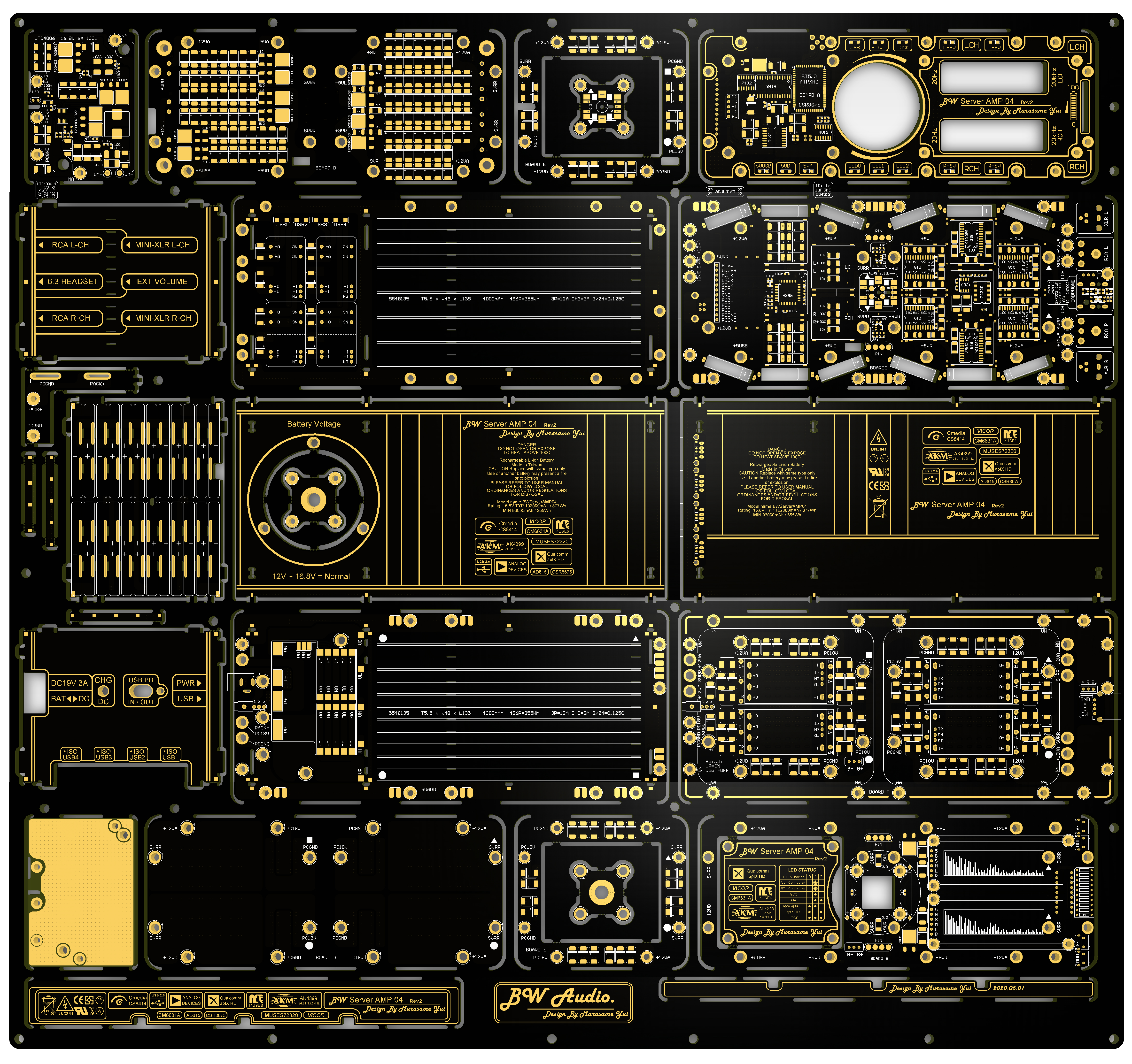

Finish PCB Transparent view

Use TexasComponent ASM2575 resistor

Old stock military wet Tantalum capacitor

VICOR isolated DC/DC converter

Furutech RCA socket

Building 3D model

Use 3D model to calculating total weight

Use VICOR DC/DC module constant power to heat wet tantalum capacitor

Start building battery

130W High power discharge test

Battery pack building

Also modify the analog voltage meter display range from 0~20V to 12~17V

The 4S Li-po battery empty at 12V and fully charge at 16.8V

Building VICOR Isolated power supply module

Building display panel

Look the-same with 3D model

USB link success

BT5.0 link success

Building AK4399 DAC / MUSES72320 digital volume control and Amplifier board by hand soldering

Add shielding case for DAC/Digital volume/amplifier chip

Final test

Lighting in the dark

Connecting with SONY BT LP player

And this is not the end.

I'm building the Aluminum case now.

I will finish this amplifier end of August.

Hope everybody enjoy my DIY process.

Thank you for watching.

I'm Murasame Yui

My full time job is high power LEV/EV battery PCB designer

Also DIY is my hobby.

So i design a battery wireless amplifier myself.

All the circuit and mechanical and PCB are design by me.

I only build one and will never mass production.

because it's too expensive.

It's spent me over 10,000 USD and 3 month.

(sorry for typing mistake, It's 10,000 USD not 100,000)

USB to Headphone

USB=>Adum3160=>CM6631A=>74HC32=>

AK4399=>MUSES72320=>AD815=>Headphone

BT 5.0 to Headphone

CSR8675=>CS8414=>74HC32=>

AK4399=>MUSES72320=>AD815=>Headphone

Battery capacity Li-po 4000mAh 4S6P = 355Wh

Amplifier

Isolated power supply

Battery & Charger

Finish PCB Transparent view

Use TexasComponent ASM2575 resistor

Old stock military wet Tantalum capacitor

VICOR isolated DC/DC converter

Furutech RCA socket

Building 3D model

Use 3D model to calculating total weight

Use VICOR DC/DC module constant power to heat wet tantalum capacitor

Start building battery

130W High power discharge test

Battery pack building

Also modify the analog voltage meter display range from 0~20V to 12~17V

The 4S Li-po battery empty at 12V and fully charge at 16.8V

Building VICOR Isolated power supply module

Building display panel

Look the-same with 3D model

USB link success

BT5.0 link success

Building AK4399 DAC / MUSES72320 digital volume control and Amplifier board by hand soldering

Add shielding case for DAC/Digital volume/amplifier chip

Final test

Lighting in the dark

Connecting with SONY BT LP player

And this is not the end.

I'm building the Aluminum case now.

I will finish this amplifier end of August.

Hope everybody enjoy my DIY process.

Thank you for watching.

Last edited:

Oh~ Sorry

It's 10,000 USD not 100,000 USD hahaha

$850 Texascomponents ASM2575 Audio resistor 50pcs

Audio (Surface Mount)

$400 Li-Po Cell 5548135 4000mAh x 4S x 6P = 24pcs

$735 VICOR DCM3623 x4

DCM3623T75X1380T00 Vicor | Mouser 臺灣

$2000 Panasonic 100uF/16V polymer Tantalum capacitor 500pcs

$2700 Military wet Tantalum capacitor 44pcs

$100 Laser cut heatsink 2pcs

$270 SMT Nuts 132pcs

$30 Aluminum knob

$60 OLED Display 2pcs

$60 WE shielding case x12

$70 CSR8675 module

$80 AK4399 chip

$100 LTC4006 charger parts

$20 S8254 Li-cell protection

$10 Cell balance board

$40 AD815 chip

$35 CM6631A board

$1333 Main PCB manufacture

$266 Meter PCB manufacture

$1400 Aluminum case

$10,492 total now

It's 10,000 USD not 100,000 USD hahaha

$850 Texascomponents ASM2575 Audio resistor 50pcs

Audio (Surface Mount)

$400 Li-Po Cell 5548135 4000mAh x 4S x 6P = 24pcs

$735 VICOR DCM3623 x4

DCM3623T75X1380T00 Vicor | Mouser 臺灣

$2000 Panasonic 100uF/16V polymer Tantalum capacitor 500pcs

$2700 Military wet Tantalum capacitor 44pcs

$100 Laser cut heatsink 2pcs

$270 SMT Nuts 132pcs

$30 Aluminum knob

$60 OLED Display 2pcs

$60 WE shielding case x12

$70 CSR8675 module

$80 AK4399 chip

$100 LTC4006 charger parts

$20 S8254 Li-cell protection

$10 Cell balance board

$40 AD815 chip

$35 CM6631A board

$1333 Main PCB manufacture

$266 Meter PCB manufacture

$1400 Aluminum case

$10,492 total now

Oh my goodness me.

That's seriously impressive.

$100,000?? What was the main cost?

Sorry it's my typing mistake.

It's 10,000USD total cost now.

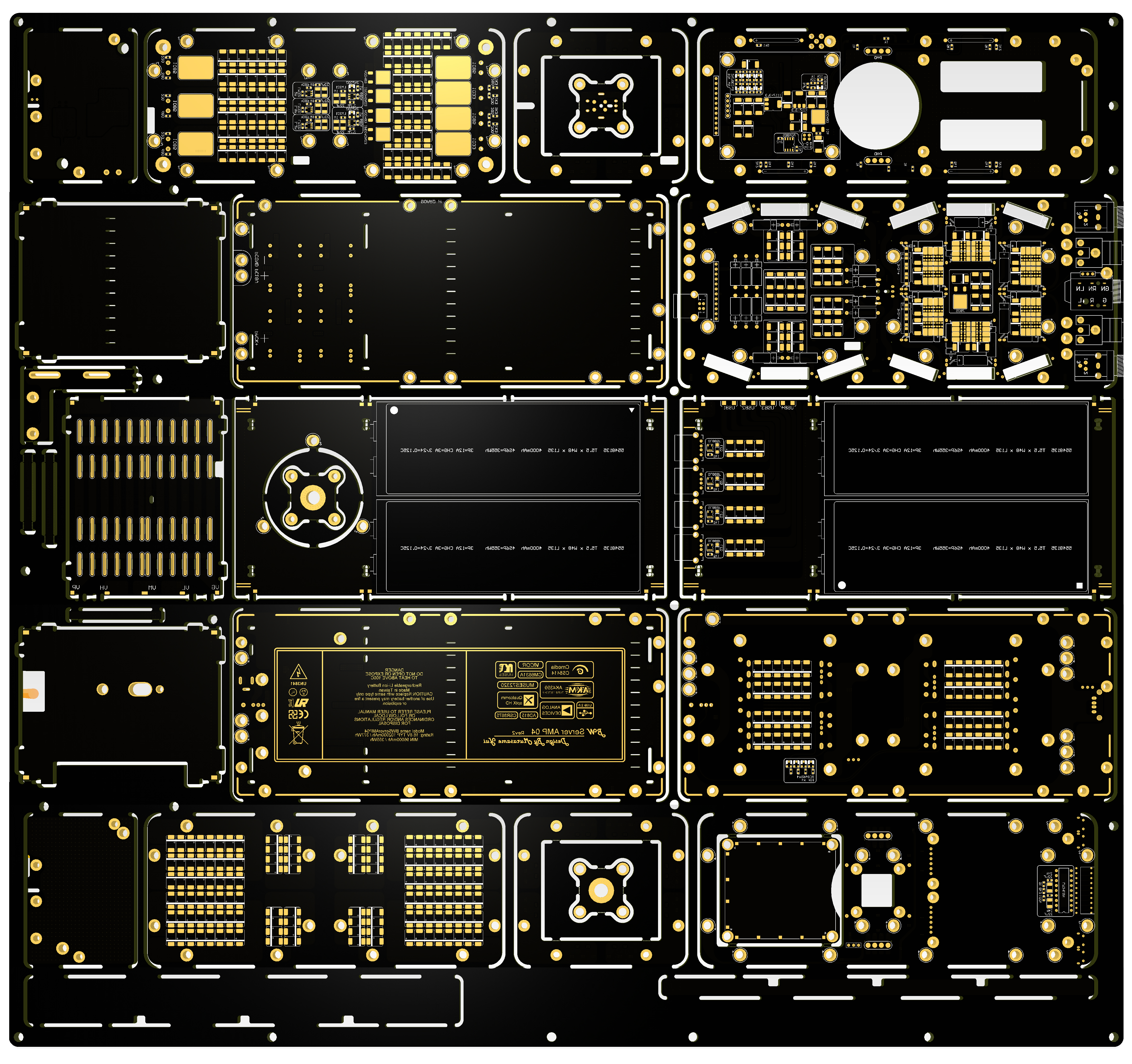

Inside the PCB

Love Symmetrical structure

Top Layer with silkscreen

Top layer Track

M1 Layer Track

M2 Layer Track

Bottom Layer Track

Bottom Layer With Silkscreen

Real PCB Panel (570 x 530mm)

Impedance control report

Very beautiful I2S square wave signal

All PCB layer view

De panel

3D Assembly Exploded view

Love Symmetrical structure

Top Layer with silkscreen

Top layer Track

M1 Layer Track

M2 Layer Track

Bottom Layer Track

Bottom Layer With Silkscreen

Real PCB Panel (570 x 530mm)

Impedance control report

Very beautiful I2S square wave signal

All PCB layer view

De panel

3D Assembly Exploded view

Last edited:

By use military wet Tantalum capacitor as AD815 OP bypass capacitor

and Texascomponnets ASM2575 resistor as signal path

With the AD815 high output current and ultra fast Differential Slew Rate 900V/s

and width 120 MHz Bandwidth (–3 dB)

You can get Strong and low but comfortable and flexible low frequency response

And precise and clear but no sense of oppression high frequency response

Feels as smooth silk with luster.

And also flat and natural mid-frequency response

And use VICOR 80W dc/dc module and ultra low internal resistance HighPower Li-Po Battery and Polymer Tantalum capacitor array

You can get Ultra-fast response ,sufficient current and stable power supply

Combining the above elements

You can get very natural and Comfortable with precise positioning sound field no matter music style

About analyser measurements

Because this amplifier very heavy and all USB/Power connector/Battery and Konb need avoid collision

I will do that after aluminum case ready.

and Texascomponnets ASM2575 resistor as signal path

With the AD815 high output current and ultra fast Differential Slew Rate 900V/s

and width 120 MHz Bandwidth (–3 dB)

You can get Strong and low but comfortable and flexible low frequency response

And precise and clear but no sense of oppression high frequency response

Feels as smooth silk with luster.

And also flat and natural mid-frequency response

And use VICOR 80W dc/dc module and ultra low internal resistance HighPower Li-Po Battery and Polymer Tantalum capacitor array

You can get Ultra-fast response ,sufficient current and stable power supply

Combining the above elements

You can get very natural and Comfortable with precise positioning sound field no matter music style

About analyser measurements

Because this amplifier very heavy and all USB/Power connector/Battery and Konb need avoid collision

I will do that after aluminum case ready.

Because I have over 100 pcs AK4399 chip in stock.

Also I have build over 45 headphone amplifier are used AK4399

AK4399 just like my old friend and I love the sound.

Also I have build over 45 headphone amplifier are used AK4399

AK4399 just like my old friend and I love the sound.

S1 37.9 degree / S2 36.7 degree / Manual point 36.2 degree

S3 Power supply capacitor array 49.2 degree

Max point /Power supply heatsink 63.8degree

The amplifier circuit zone will stay at 50~58 degree

It's make wet Tantalum capacitor sound more smooth and warm

S3 Power supply capacitor array 49.2 degree

Max point /Power supply heatsink 63.8degree

The amplifier circuit zone will stay at 50~58 degree

It's make wet Tantalum capacitor sound more smooth and warm

Because I have over 100 pcs AK4399 chip in stock.

Also I have build over 45 headphone amplifier are used AK4399

AK4399 just like my old friend and I love the sound.

Ahh fair enough. Would be interesting to see how it measures. Although it’s unlikely anyone can hear the differences between those chips if implemented well (which looks like it has been!)

I'm interesting how it measures too.🙂

So I need to finish the glass panel and aluminum case asap

So I need to finish the glass panel and aluminum case asap

Oh~ Sorry

It's 10,000 USD not 100,000 USD hahaha

$850 Texascomponents ASM2575 Audio resistor 50pcs

Audio (Surface Mount)

$400 Li-Po Cell 5548135 4000mAh x 4S x 6P = 24pcs

$735 VICOR DCM3623 x4

DCM3623T75X1380T00 Vicor | Mouser 臺灣

$2000 Panasonic 100uF/16V polymer Tantalum capacitor 500pcs

$2700 Military wet Tantalum capacitor 44pcs

$100 Laser cut heatsink 2pcs

$270 SMT Nuts 132pcs

$30 Aluminum knob

$60 OLED Display 2pcs

$60 WE shielding case x12

$70 CSR8675 module

$80 AK4399 chip

$100 LTC4006 charger parts

$20 S8254 Li-cell protection

$10 Cell balance board

$40 AD815 chip

$35 CM6631A board

$1333 Main PCB manufacture

$266 Meter PCB manufacture

$1400 Aluminum case

$10,492 total now

Very impressive project!

I can see the costs perhaps are due to the large quantities of components.

It looks like you have enough parts for 10, not a single project.

- Home

- Amplifiers

- Headphone Systems

- My DIY BT5.0 headphone amplifier