You all are awesome! I feel kinda scumbagish for asking a question then not even being part of the conversation, but I will go back and read and study what has been posted. Then give HornResp another good shot.

If you've got a USB soundcard and a couple of adapters, it's worth double-checking the T/S parameters before committing to a build.

As a sanity-check, what does a ported box give you?

Chris

Still working on that sanity check😱 Prognosis is questionable.

What hardware would you recommend for using a USB soundcard? I have the cheapo Berhinger UCS-202/222, but mostly for the optical output. I really dont use the line level I/O. If there is a good tutorial you could point me to, I would happily read that instead of relying on you to type everything out here. Last time I modeled a speaker, I was still in the industry(sorta) and had access to state of the art tech....from the late 90's. Not sure how relevant it still is today. I also have an old analog Oscope if that helps. I have a few different drivers that I need to test. Any further direction would be greatly appreciated.

When I 'run the numbers' I get a 500 L net compression horn, which converted to parabolic, while smaller, looks horrible, or ~450 L net TH, leaving TTQWT the only viable horn @ ~148 L net to compare to the reflex.

GM

148L should be more than enough. I did a quick calc->conversion and I can comfortably have somewhere around 250L(look ma, I did METRIC!!!) per enclosure.

TTQWT sounds a bit daunting, but I will defer to your knowledge. If you really think that is the only viable horn. I had considered just doing a simple BR, but I really want to do something special with these drivers, and yeah, I have a thing for horns. First intro to Hi-Fi was my Uncle's VOTT A7's....been hooked ever since.

sorry on the expansion. This cabinet fits those constraints - maybe eyeball its hornresp input - if looks good - buy the plan.

https://i.imgur.com/0sLjk.jpg

For sure will look into this. I think it might be a bit taller than what would be ideal. Thats why I was trying to go for a single fold to keep the overall dimensions less than about 425mm "tall"(while on back) or "deep"(while standing up for home use). I hate to post it, but I do have some "chicken scratches" that I have done that might better illustrate what I am going for. I will draw it up in AutoCad after I get a better idea of just what I am going to be building. I am not afraid of a bit of woodworking. 😀

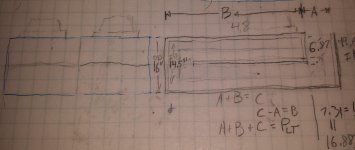

Again, forgive the poor drawings, they are just what I use to get my mind going... usually dont share, ever. Very basic beginning, the drivers are invert mounted here on the "outside" of the enclosure. On the left is a side profile of it on its "back", and on the right is what the two enclosures would look like side by side in the back of my truck, again they will be indoor speakers probably 99% of the time. Ignore the basic maths...I got far enough into the thought process that I assumed(and obviously was correct) that someone had already done all that mess; no since reinventing the wheel, now I just need to learn how to roll it.....

😱

😱Attachments

Regardless, if its build complexity poses no problems for the OP, then on paper it looks to be the best performer overall; otherwise my simple one fold TTQWT.

GM

Build complexity is no problem at all. 3rd generation woodworker, been building custom speakers since I was a teenager, in fact I relish the challenge. Almost as much as the design. But I am thinking that that simple one fold TTQWT is gonna be the way to go.

I am going to give HornResp another good go this evening after I finish up replying here. Again, yours, and everyone else's help is tremendously appreciated. (I have a feeling I will be saying that alot...lol)

I don't know of a service to store the text files - FWIW - here it is pasted, Your pipe reaches real low. The horn does more in its midbass area but looks pretty complex to build. Is the flare usually parabolic for a constant width expansion within two parallel walls? (I see conic descriptions often for segments)

??? Freddy, gimme a break! Me and others have posted numerous times how to export files, which auto saves in the 'export' folder inside the HR folder, then all you do is use the forum's 'manage attachments' to attach it to your email.

Right, when using flat/straight baffle boards to divide a parallel wall space, it's a parabolic expansion, though most times the conical sim is close enough, but sometimes not so much, so best to always check.

Note I sim, save using conical since parabolic really slows down my machine.

GM

??? Freddy, gimme a break! Me and others have posted numerous times how to export files, which auto saves in the 'export' folder inside the HR folder, then all you do is use the forum's 'manage attachments' to attach it to your email.

Right, when using flat/straight baffle boards to divide a parallel wall space, it's a parabolic expansion, though most times the conical sim is close enough, but sometimes not so much, so best to always check.

Note I sim, save using conical since parabolic really slows down my machine.

GM

I might add...kinda sheepishly, that I was able to download the TTQWT text file to the HR import file and go directly from there in HR. I think I am doing this right. Pretty cool!!!

Well needed to stretch the legs and I guess make this official. Those zip ties had been on far too long, and yet dust still managed to get on the cones...sigh....this is why I am wanting to use these...just to knock the dust off em....🙂 Well and maybe show off a little bit. 😎🙄

Now if I could just figure out how to use my stupid cellphone camera.... I want my AE-1 back....of course I would still be developing the....oh I digress.... Thank you all again. Enjoy!(1990's JBL Car Audio at its BEST)

Now if I could just figure out how to use my stupid cellphone camera.... I want my AE-1 back....of course I would still be developing the....oh I digress.... Thank you all again. Enjoy!(1990's JBL Car Audio at its BEST)

Attachments

If those 1500Gtis are anything like the smaller 12" 1200Gtis, you've got a good pair of drivers there.

The good news is that the Xmax is likely more than the quoted figure, which is based on a simple coil vs. gap calculation. Measured Xmax for the 1200Gti was something like 12mm, for example.

The bad news is that the 1200Gti could suffer from cone sag if left too long with the cone facing up, and the dust cap could suffer from dry rot.

The good news is that the Xmax is likely more than the quoted figure, which is based on a simple coil vs. gap calculation. Measured Xmax for the 1200Gti was something like 12mm, for example.

The bad news is that the 1200Gti could suffer from cone sag if left too long with the cone facing up, and the dust cap could suffer from dry rot.

If those 1500Gtis are anything like the smaller 12" 1200Gtis, you've got a good pair of drivers there.

The good news is that the Xmax is likely more than the quoted figure, which is based on a simple coil vs. gap calculation. Measured Xmax for the 1200Gti was something like 12mm, for example.

The bad news is that the 1200Gti could suffer from cone sag if left too long with the cone facing up, and the dust cap could suffer from dry rot.

They are fairly similar to the 1200s, as much as the 1800s and so on. At one time I had 4 of these 15s, two I sold NIB a few years back. Yeah the "sag" is strong in these lines, I had a pair of the 18s that were very bad; but these 15's have been fairly well taken care of...I even flipped the clam shelled drivers over every 6 months or so, just to avoid that problem. These are like new, came out of a show car system that was barely used. They have never been in an "outdoor" car environment, always climate controlled.

Never seen one of the dust caps rot though, seen plenty pushed in sadly. Here is an old family pic...all I have left are the two fifteens pictured above. I had originally planned on doing the 18's, but they needed recones, and the auto cone is no longer available as far as I know, but they can be reconed with the pro driver parts, but they arent the same(lighter cone among other things if I remember correctly).

Attachments

The x-max number is actually correct. I used to have a 1500GTi and liked it a lot but it was short on the X-max department, those drivers have a short VC, only 19mm if I’m not mistaken.If those 1500Gtis are anything like the smaller 12" 1200Gtis, you've got a good pair of drivers there.

The good news is that the Xmax is likely more than the quoted figure, which is based on a simple coil vs. gap calculation. Measured Xmax for the 1200Gti was something like 12mm, for example.

The bad news is that the 1200Gti could suffer from cone sag if left too long with the cone facing up, and the dust cap could suffer from dry rot.

I also had the 1000GTi model (10”).

The x-max number is actually correct. I used to have a 1500GTi and liked it a lot but it was short on the X-max department, those drivers have a short VC, only 19mm if I’m not mistaken.

I also had the 1000GTi model (10”).

So, if I can ask, how were you running the 15", were you running one or multiples? Specifics, down to the vehicle, equipment and sub placement are the kind of info I like to hear/learn about; what worked and what did not. If you ran out of xmax, were you overdriving the sub? What kind of music were you playing? All of this is a great help for me determining if this driver really is a good candidate for this type of folded enclosure. Of course, if you can just share the basics that would be understood and appreciated as well. I dont usually share that much myself....a few reasons mentioned below.

I guess it really depends on just how hard they are driven and how they are used. I kind of look at these drivers as collectors' items, too nice to sit in a vehicle and be subjected to the *wonderful* weather here in Missouri(dont like the weather here? Just wait a day....it will change). With those wide swings, nasty hot summers, just plain weird winters, and the lack of Spring or Fall....for the most part: I just dont want to "install" any of the stuff I have collected over the years that is in good or better condition.

Well, that and some people around here have "sticky fingers", so if or when I do install a "system" it is always total stealth. I learned that one the hard way at the first and only car audio competition I went to compete in...I showed off all my stuff and had the system stolen not soon after. They even knew where to cut my *back-up battery* for the alarm....so yeah, they only time I showed that stuff was at that comp. Lesson learned. 😡

That and I wasnt even allowed to compete anyway...they didnt know what class I should be in; so it was just an exibition entry. I was technically a distributor for a couple product lines(even though I was only 18), and I was MECP certified. But my relatively low budget system, couldnt come close to competing with the top tier company owned demo vehicles(where they wanted to put me...sigh).

... yeah I know.... 20+ years and I am still a bit bitter about losing my first real amp(Autotek 7204) and a very rare and mint Autotek 7050XX high current amp. SMDH, I really hate a thieves...

... yeah I know.... 20+ years and I am still a bit bitter about losing my first real amp(Autotek 7204) and a very rare and mint Autotek 7050XX high current amp. SMDH, I really hate a thieves...I loved the 1000GTi, had plans on using the pair I had in a Lincoln MkVIII a few years back, but I ended up having to sell both the drivers and the car(and a *bit* more of my collection...life can be cruel, but it could of been worse).

Regardless, its nice to hear from another enthusiast for these old drivers. I spent plenty of time drooling over these back before I started installing for a shop that sold them. Of course by the time I could afford them, they had discontinued the line. Oh well...I eventually found most of what I have now in the early days of CL and Fleabay.

Sorry for the ramble down memory lane...guess I need to get back to figuring out how to fold the horn modeled by GM. 🙄

When I 'run the numbers' I get a 500 L net compression horn, which converted to parabolic, while smaller, looks horrible, or ~450 L net TH, leaving TTQWT the only viable horn @ ~148 L net to compare to the reflex.

GM

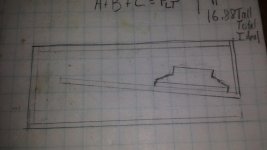

Well I jumped back into my chicken scratching mode(but made the effort to reach the whole 18"s to one of my straight edges so it doesnt look so bad). Obviously not drawn to scale.

I thought I understood the basic way to fold a horn from the info in HornResp, but this is what I came up with for build instructions(yes I had to google it...not new to taped or tapped, but combining the two is throwing me for a loop).

The layout you came up with from HR is attached, along with my preliminary drawing. What I am confused about is how the driver appears in HR to be at the mouth of the vent, but doing so puts the "other side" of the driver at the "end" of the big end of the enclosure, not in the middle per HR. At least that is how I interpreted it.

I have been thinking that HR might be trying to tell me its a double folded horn, when I really need a single fold to make it work with the space restrictions.

Any help or advice would be greatly appreciated... As much as I like to truly DIY stuff for myself, this has me a bit confused right now and I really want to make sure I have the best plans available before I start cutting material... and again I dont want to just ghost this thread or let it die(unless there is a consensus I should, I will admit my forum etiquette is very rusty....I blame Facebook...

🙄

🙄 That being said I know I am walking a fine line between DIY and needing to pay for plans. Obviously I prefer, but am also financially restricted, to the former. I am in no big hurry, I also have some health issues that severely limit the time I can spend actually "doing work", and this project though important has taken a back seat in just the past few days....such is life. I still would like to get it done if only to use those drivers, I really do hate seeing them just sit there.

Attachments

148L should be more than enough. I did a quick calc->conversion and I can comfortably have somewhere around 250L(look ma, I did METRIC!!!) per enclosure.

TTQWT sounds a bit daunting, but I will defer to your knowledge. If you really think that is the only viable horn. I had considered just doing a simple BR, but I really want to do something special with these drivers, and yeah, I have a thing for horns. First intro to Hi-Fi was my Uncle's VOTT A7's....been hooked ever since.

If Freddy's horn sim is close, it's too big at 336 L net, so a bit bigger once built.

Tapped Tapered Quarter Wave Tube is bog simple, just an inverse tapered TQWT that folds back on itself to 'tap' the backside of the driver 1/2 WL away to fill in a TL's inherent 3rd harmonic dip. Not many 'free lunches' in audio design, but this is one of them: http://www.danleysoundlabs.com/wp-content/uploads/2012/01/The-Tapped-Horn.pdf

The driver's specs are such that it wants more bulk than you have available and maybe one of the new [to HR] 8th order band pass [BP8] will net some minor increase in power handling due to being a bit bigger, but for now others will have to sim those variations.

Ah! DIYed a pair of A7-500 using 3/4" no void marine grade in '64, moving up to a derived three channel A2 system in '70 thanks to the gutting of a local cinema. Later, switched to just stereo, converted the horns to compression loaded [cut off all of the reflex back box], added dual 515B ~30-120 Hz 'subs', all configured for a corner loaded 'stack', though over time have progressively lowered them to ~14 Hz. HF has varied over time, settling on 300 Hz Harry Olson inspired conical WGs w/dual Altec 802 drivers before health issues forced a 'fire sale' in 2000 that left me without electronics and only the subs plus a pair of 511B/802D horns with blown diaphragms.

GM

GM

Sure. I used a single 1500GTi, I had it in an 85L box tuned around 35hz in a 300ZX ('87 Z31). It was powered by a Zed Audio ESX amp from 30hz to 90hz, up front I ran a set of Vifa P17's midbass , JBL 400GTi midranges and Vifa soft dome tweeters also powered by Zed Audio ESX amps. I didn't have problems with X-max, this was a SQ setup. I listen to many kinds of music, from jazz, classic rock, metal, synth pop, old school Euro dance music and techno.So, if I can ask, how were you running the 15", were you running one or multiples? Specifics, down to the vehicle, equipment and sub placement are the kind of info I like to hear/learn about; what worked and what did not. If you ran out of xmax, were you overdriving the sub? What kind of music were you playing? All of this is a great help for me determining if this driver really is a good candidate for this type of folded enclosure. Of course, if you can just share the basics that would be understood and appreciated as well. I dont usually share that much myself....a few reasons mentioned below.

I guess it really depends on just how hard they are driven and how they are used. I kind of look at these drivers as collectors' items, too nice to sit in a vehicle and be subjected to the *wonderful* weather here in Missouri(dont like the weather here? Just wait a day....it will change). With those wide swings, nasty hot summers, just plain weird winters, and the lack of Spring or Fall....for the most part: I just dont want to "install" any of the stuff I have collected over the years that is in good or better condition.

Well, that and some people around here have "sticky fingers", so if or when I do install a "system" it is always total stealth. I learned that one the hard way at the first and only car audio competition I went to compete in...I showed off all my stuff and had the system stolen not soon after. They even knew where to cut my *back-up battery* for the alarm....so yeah, they only time I showed that stuff was at that comp. Lesson learned. 😡

That and I wasnt even allowed to compete anyway...they didnt know what class I should be in; so it was just an exibition entry. I was technically a distributor for a couple product lines(even though I was only 18), and I was MECP certified. But my relatively low budget system, couldnt come close to competing with the top tier company owned demo vehicles(where they wanted to put me...sigh).... yeah I know.... 20+ years and I am still a bit bitter about losing my first real amp(Autotek 7204) and a very rare and mint Autotek 7050XX high current amp. SMDH, I really hate a thieves...

I loved the 1000GTi, had plans on using the pair I had in a Lincoln MkVIII a few years back, but I ended up having to sell both the drivers and the car(and a *bit* more of my collection...life can be cruel, but it could of been worse).

Regardless, its nice to hear from another enthusiast for these old drivers. I spent plenty of time drooling over these back before I started installing for a shop that sold them. Of course by the time I could afford them, they had discontinued the line. Oh well...I eventually found most of what I have now in the early days of CL and Fleabay.

Sorry for the ramble down memory lane...guess I need to get back to figuring out how to fold the horn modeled by GM. 🙄

After I sold this car I got VW Corrado and this was too big so I moved the 1500GTi to use at how but at home without the cabin gain the 85L box didn't do so well so I shelved it for a while and a couple of years later I actually gave it to a friend.

In the Corrado I used a single 1000GTi also ported but around 38hz, don't remember the box size tho, powered by an ESX Q2751 amp It did great with most music but with songs that had very low content it lacked a bit. I also tried it with a Diamond Audio D3 and D5 amp. Eventually I had a problem with it where part of the spider came unglued so I had to repair it but shortly after I redid the whole system (downsized) and replaced it with a single JBL 804GTO in a tiny 8.5L sealed box and was actually happier with it, content bellow 50hz got noticeably better. Up front in the Corrado I ran Peerless CSX midbass and Aurasound Whispers, Clarion HX-D10 head unit with the outside DSP processor + Clarion EQ and 6 disc changer, old school RF Power 400.4 and Power 360.2 amps. Despite it being a much smaller system it was the system I was most happy with, it just did everything rights.

Nowadays I don't have anything in my current car but I'm planing on doing something similar to what I had in the Corrado, Aurasound Whispers, up in the dash, some midbass in the door and the single 8" sealed in the trunk.

At home now I use a pair of Aurasound NS8's in a 6th order bandpass and I'm fairly happy with the results, it does a really good job from 30hz and up.

The layout you came up with from HR is attached, along with my preliminary drawing.

Right, you folded it into a basic tapped TQWT, just not the offset folded I simmed [forms a 'J' in simplest fold]. 🙁

Here's your fold, which doesn't fill in its 3rd harmonic dip, but does play a little louder due to its narrower BW:

GM

Attachments

Right, you folded it into a basic tapped TQWT, just not the offset folded I simmed [forms a 'J' in simplest fold]. 🙁

Here's your fold, which doesn't fill in its 3rd harmonic dip, but does play a little louder due to its narrower BW:

GM

I havent even looked at the file yet, but THANK YOU!!

Life has been unexpectedly crazy lately, and really dont even have time now to be on here(even now)....but rest assured I will see this project to fruition.

I will get back here as soon as I can and might even make some sawdust...

Thanks to you all again, this is a fantastic community.

You're welcome! Looking forward to how it turns out.

GM

I will do my best to keep this up to date as time and finances allow. Might even be able to get some build pics... 😉

That being said, I modeled the v.2 that you gave me, and I *might* like that FRC a bit better, I really dont need much above 100Hz and the bumped output is a bonus. But that begs the question, how important is that "third harmonic"?

I think I have figured out how to make the "j-turn" you first suggested, seems rather simple now.....doh!

My "shop" is full of other projects, so this is still probably a few weeks out before I make any saw dust. So back to studying... cant sleep anyway...🙁

Again many thanks....

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Multipurpose enclosures for JBLGTi 1500Mk1(2226 based)