baudouin0,

Good catch!

30% UL.

Another thing I notice about that circuit is:

It puts the screens Quiescent DCV at 75% of the UL Tap Quiescent DCV.

Suppose the UL tap is at 400V. In that case, the screens are at 300V quiescent.

That is Lots easier on the screens in terms of the maximum screen current during the time when the plate is going low voltage on its way toward the cathode.

At 30% UL, If the plate goes to 50V, the change is 350V. 30% of 350V = 105V, that puts the screen at 300V - 105V = 195V

Look at the curves to find the screen current for Vp = 50V, Vg = 0V, and Vs = 195V.

Not too much screen current.

At 40% UL, If the plate goes to 50V, the change is 350V. 40% of 350V = 140V, that puts the screen at 400V - 140V = 260V

Look at the curves to find the screen current for Vp = 50V, Vg = 0V, and Vs = 260V.

Lots more screen current.

How is that for a little bit more analysis?

Good catch!

30% UL.

Another thing I notice about that circuit is:

It puts the screens Quiescent DCV at 75% of the UL Tap Quiescent DCV.

Suppose the UL tap is at 400V. In that case, the screens are at 300V quiescent.

That is Lots easier on the screens in terms of the maximum screen current during the time when the plate is going low voltage on its way toward the cathode.

At 30% UL, If the plate goes to 50V, the change is 350V. 30% of 350V = 105V, that puts the screen at 300V - 105V = 195V

Look at the curves to find the screen current for Vp = 50V, Vg = 0V, and Vs = 195V.

Not too much screen current.

At 40% UL, If the plate goes to 50V, the change is 350V. 40% of 350V = 140V, that puts the screen at 400V - 140V = 260V

Look at the curves to find the screen current for Vp = 50V, Vg = 0V, and Vs = 260V.

Lots more screen current.

How is that for a little bit more analysis?

Last edited:

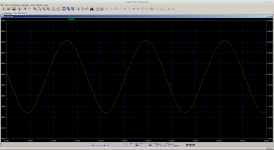

The simulation agrees.

For the same output clipping level would need to increase the HT from 450 to 510v. But even with this change the peak screen current drops from 54ma to 36ma. For 600v HT I can get 180W output rather than 120W out of the circuit and 44ma peak screen.

Does seem to be something in this.

For the same output clipping level would need to increase the HT from 450 to 510v. But even with this change the peak screen current drops from 54ma to 36ma. For 600v HT I can get 180W output rather than 120W out of the circuit and 44ma peak screen.

Does seem to be something in this.

Last edited:

baudouino,

Wow!

I am impressed with your ability to do simulation.

Thanks!

I do not go that deep (and I hate running any software).

So what am I doing on this computer?

Three place slide rule accuracy is enough to get you into moon orbit, without overshooting, and without hitting the moon.

(But only if you also do a mid course correction).

Wow!

I am impressed with your ability to do simulation.

Thanks!

I do not go that deep (and I hate running any software).

So what am I doing on this computer?

Three place slide rule accuracy is enough to get you into moon orbit, without overshooting, and without hitting the moon.

(But only if you also do a mid course correction).

Last edited:

I can now see its not a new idea. I found something on diyaudio before, but they had to use a separate winding on the OPT for the UL part.

Did not work for hubble.

Did not work for hubble.

Sometimes using fundamental tests on telescopes prevents having to install "glasses" on the telescope while it is in space.

Having made calibrated electronic measurements since 1959, I am sometimes amazed how old fundamental measurements are still needed and/or the easiest to make.

For example a scope XY display for one.

I had someone who wanted to set the frequency of a 10MHz oscillator, and adjust it to match the precision 10MHz house reference.

He did not have a frequency counter.

I told him XY does the trick.

Having made calibrated electronic measurements since 1959, I am sometimes amazed how old fundamental measurements are still needed and/or the easiest to make.

For example a scope XY display for one.

I had someone who wanted to set the frequency of a 10MHz oscillator, and adjust it to match the precision 10MHz house reference.

He did not have a frequency counter.

I told him XY does the trick.

Using a mosfet for UL in cases where the OPT had no tap was discussed a lot in this forum 10 to 12 years ago and several of us had circuits that worked.

Adjustable distributed load discussion

Adjustable distributed load discussion

Tubelab_com,

I know you merely used / repeated the term that has been mis-used for years . . . distributed load.

Not your fault.

I hate what they started calling Ultra Linear:

"Distributed Load"

It became a household word, like Kleenex.

UL in a practical sense passes very little power from the screens to the output transformer through the UL taps.

A 40% UL tap is 0.4 x 0.4 = 0.16 times the Plate impedance.

1/(0.16) = 6.25.

So, for every 1 mA change of plate current, you have to have 6.25 mA change of screen current to get the same power contribution from the screen as you get from the plate.

Most screen currents do not approach plate currents until the tube gets in an area that does 2 things:

1. Cooks screens

2. Gets very non linear

That is not exactly a distributed load (the plate takes almost all the load, just like an Ox that is tied to a Squirrel so they can plow the field).

Think of the poor Squirrel that is tied to a lazy Ox.

Distributed Load?

In what book of logic?

Did I miss something?

I know you merely used / repeated the term that has been mis-used for years . . . distributed load.

Not your fault.

I hate what they started calling Ultra Linear:

"Distributed Load"

It became a household word, like Kleenex.

UL in a practical sense passes very little power from the screens to the output transformer through the UL taps.

A 40% UL tap is 0.4 x 0.4 = 0.16 times the Plate impedance.

1/(0.16) = 6.25.

So, for every 1 mA change of plate current, you have to have 6.25 mA change of screen current to get the same power contribution from the screen as you get from the plate.

Most screen currents do not approach plate currents until the tube gets in an area that does 2 things:

1. Cooks screens

2. Gets very non linear

That is not exactly a distributed load (the plate takes almost all the load, just like an Ox that is tied to a Squirrel so they can plow the field).

Think of the poor Squirrel that is tied to a lazy Ox.

Distributed Load?

In what book of logic?

Did I miss something?

Last edited:

From ahanuban - 2014

Another question concerning an ultra-linear push-pull output stage.

Suppose we have a tube with a screen grid voltage rating lower than its plate voltage rating by 0 to 40%. In order to operate the tube near its maximum plate voltage, we would normally use a transformer with a separate ultra-linear winding rather than a tap on the primary (such as the Acrosound TO-350). This way, the ultra-linear winding only acts as negative feedback (AC-coupled to the screen), and the DC screen voltage is provided by a separate DC supply.

I am wondering, given a standard ultra-linear transformer (one primary winding with 40% voltage tap), could one simply use a coupling capacitor in series with the screen grid, connecting a separate screen DC supply after the capacitor? If not, why not?

Another question concerning an ultra-linear push-pull output stage.

Suppose we have a tube with a screen grid voltage rating lower than its plate voltage rating by 0 to 40%. In order to operate the tube near its maximum plate voltage, we would normally use a transformer with a separate ultra-linear winding rather than a tap on the primary (such as the Acrosound TO-350). This way, the ultra-linear winding only acts as negative feedback (AC-coupled to the screen), and the DC screen voltage is provided by a separate DC supply.

I am wondering, given a standard ultra-linear transformer (one primary winding with 40% voltage tap), could one simply use a coupling capacitor in series with the screen grid, connecting a separate screen DC supply after the capacitor? If not, why not?

If you tie the squirrel to the lazy ox (triode mode) you don't get as much plowing as if the ox slows down so does the squirrel. Better for the squirrel to follow the ox around giving orders (UL mode). Think I need to get out more.

Was UL mode a term that was coined/patented at the time. I see in Mullard books it is always called distributed load.

'Ultra-linear' is a special case of 'distributed loading'; a circuit technique patented by Alan Blumlein in 1937 (Patent No. 496,883), although the name 'distributed loading' is probably due to Mullard.[1] In 1938 he applied for the US patent 2218902.

Was UL mode a term that was coined/patented at the time. I see in Mullard books it is always called distributed load.

'Ultra-linear' is a special case of 'distributed loading'; a circuit technique patented by Alan Blumlein in 1937 (Patent No. 496,883), although the name 'distributed loading' is probably due to Mullard.[1] In 1938 he applied for the US patent 2218902.

Last edited:

My Post # 8 had a math error.

I apologize.

We need a change of 2.5 mA screen current into a 40% Ultra Linear Tap,

in order to get the same signal power resulting from a change of only 1 mA of plate current into 100% of the same primary winding

(100% of whole winding for Single Ended; and 100% of winding from plate connection to center tap for Push Pull).

For an EL84, I think one of the optimum UL configurations has the UL tap at 25%.

We need the screen current to change 4 mA in order to have the same signal power resulting from changing the plate current by only 1 mA.

It is a case of a German Shepherd (Screen) pulling a plow with an Ox (Plate).

Not surprisingly, the Ox (plate) does most of the work.

I say again, most screen current changes do not approach plate current changes until the tube gets in an area that does 2 things:

1. Cooks screens

2. Gets very non linear

But I still do not like the term "Distributed Load" to describe Ultra Linear.

Marketing can always come up with a great word to sell the concept.

The concept is that we are getting more power because of the extra power from the screen.

But we get more power from UL because the effective gain is higher than in triode mode, and the plate resistance is higher in UL than in triode mode

(the lower rp in triode mode uses up some of the power, but it does give a lower output impedance; that gives a higher damping factor).

I do like to use Ultra Linear in some of my amplifiers, but I use it because I get more power than the same tube in Triode mode, and I get a lower output impedance than in Pentode / Beam Power mode.

Tradeoffs, Tradeoffs, Tradeoffs.

I apologize.

We need a change of 2.5 mA screen current into a 40% Ultra Linear Tap,

in order to get the same signal power resulting from a change of only 1 mA of plate current into 100% of the same primary winding

(100% of whole winding for Single Ended; and 100% of winding from plate connection to center tap for Push Pull).

For an EL84, I think one of the optimum UL configurations has the UL tap at 25%.

We need the screen current to change 4 mA in order to have the same signal power resulting from changing the plate current by only 1 mA.

It is a case of a German Shepherd (Screen) pulling a plow with an Ox (Plate).

Not surprisingly, the Ox (plate) does most of the work.

I say again, most screen current changes do not approach plate current changes until the tube gets in an area that does 2 things:

1. Cooks screens

2. Gets very non linear

But I still do not like the term "Distributed Load" to describe Ultra Linear.

Marketing can always come up with a great word to sell the concept.

The concept is that we are getting more power because of the extra power from the screen.

But we get more power from UL because the effective gain is higher than in triode mode, and the plate resistance is higher in UL than in triode mode

(the lower rp in triode mode uses up some of the power, but it does give a lower output impedance; that gives a higher damping factor).

I do like to use Ultra Linear in some of my amplifiers, but I use it because I get more power than the same tube in Triode mode, and I get a lower output impedance than in Pentode / Beam Power mode.

Tradeoffs, Tradeoffs, Tradeoffs.

Last edited:

baudouin0,

In answer to your post #9 question:

If you AC couple the UL tap to the screen, and you supply DC current to the same screen, then the DC current either has to come from a resistor that is connected to a + voltage, or from a current source.

You can not AC couple the UL tap to a screen that is DC connected to a constant voltage screen supply, or it will short out the AC of the UL tap.

Using a resistor to supply the DC screen current means the UL tap has to drive both the parallel impedance of the screen and the screen resistor.

If you use a current source, then the UL tap only has to drive the screen impedance.

Hmmm . . . that is an idea.

One thing to remember is that the screen impedance is not a constant when the tube has signal applied. I believe that to be true whether the tube is in Pentode / Beam Power mode, UL mode, or Triode mode.

In answer to your post #9 question:

If you AC couple the UL tap to the screen, and you supply DC current to the same screen, then the DC current either has to come from a resistor that is connected to a + voltage, or from a current source.

You can not AC couple the UL tap to a screen that is DC connected to a constant voltage screen supply, or it will short out the AC of the UL tap.

Using a resistor to supply the DC screen current means the UL tap has to drive both the parallel impedance of the screen and the screen resistor.

If you use a current source, then the UL tap only has to drive the screen impedance.

Hmmm . . . that is an idea.

One thing to remember is that the screen impedance is not a constant when the tube has signal applied. I believe that to be true whether the tube is in Pentode / Beam Power mode, UL mode, or Triode mode.

Last edited:

Was UL mode a term that was coined/patented at the time. I see in Mullard books it is always called distributed load.

'Ultra-linear' is a special case of 'distributed loading'; a circuit technique patented by Alan Blumlein in 1937 (Patent No. 496,883), although the name 'distributed loading' is probably due to Mullard.[1]

"Ultralinear" was typically used by Parmeko, Partridge and GEC.

My Dad always used that term for it and he worked at Mullard. 🙄

#9 is not my idea I just found it on another old post.

You could wire a dual gang pot between each plate and HT. Wire each centre to two emitter followers, and then to each screen. One end you will have triode - the other pentode and somewhere in between UL.

You would have to use the spindle as isolation. Again seem something in diyaudio on this but using mosfets. You could even use cathode followers onto the screen.

You could wire a dual gang pot between each plate and HT. Wire each centre to two emitter followers, and then to each screen. One end you will have triode - the other pentode and somewhere in between UL.

You would have to use the spindle as isolation. Again seem something in diyaudio on this but using mosfets. You could even use cathode followers onto the screen.

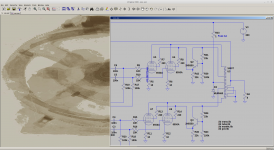

You could feed the emitter (or source 😉) followers (but not their voltage dividers!) from the supply voltage directly. Thus the OPT's windings were relieved from the screen current. Or were you hoping to yield more output power with feeding the screens from the UL taps?View attachment 813402

Is this a way of getting more power out of the UL connection. Basically dividing the screen voltage down a bit. This will reduce the UL from 40% to 30%. Am I missing something?

Best regards!

Interesting story I heard about the Hubble screwup:

I worked in the precision optical industry for many years. I met a fellow whose buddy was involved with the Hubble testing before it was sent up. There was a fundamental, but very simple error, in the optical test equipment (they didn't find this out until after the telescope was launched). Anyway, the buddy involved in the testing was sceptical about the test results so he suggested a second test to verify the first. This second test would have cost about $1 million but would have removed all doubt. His proposal was shot down.

Cheers, Steve

I worked in the precision optical industry for many years. I met a fellow whose buddy was involved with the Hubble testing before it was sent up. There was a fundamental, but very simple error, in the optical test equipment (they didn't find this out until after the telescope was launched). Anyway, the buddy involved in the testing was sceptical about the test results so he suggested a second test to verify the first. This second test would have cost about $1 million but would have removed all doubt. His proposal was shot down.

Cheers, Steve

Interesting story, indeed! I've heard that they managed to compensate for this optical error software wise. Is this true?

Best regards!

Best regards!

You could feed the emitter (or source 😉) followers (but not their voltage dividers!) from the supply voltage directly. Thus the OPT's windings were relieved from the screen current. Or were you hoping to yield more output power with feeding the screens from the UL taps?

Best regards!

Yes you can feed the collector from the HT providing the base does not overtake the HT. In simulation made very little difference to the output level or the distortion. The screen current and plate current virtually track by a constant ratio.

What it does do is reduces the screen dissipation allowing for a higher HT and hence more output power from the same valve. You could also use it where the OPT has no UL connection.

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- More power out of UL connection