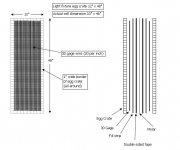

Here is my drawing of a proposed ESL. The item shown as a fill spacer is to go around the outside edge and be the same thickness as the 30 gage, then I can stick 1/16 double sided tape to this, to give me the space between the wire and mylar. I did not want the tape to stick to the wire. Now 30 gage is .010 and not sure what I could use to epoxy to the crate. Also I would be using a sub I have so the panel does not have to operate below 200. Thoughts...

Attachments

Could you cut notches in the plastic grid with a Dremel tool to set the wires into? Then use model airplane cement, since the grids are made of polystyrene, to fill in the top of the notch and hold in the wire? Melting might work too, a la Quad. What kind of insulation will the wires have?

Guess you could cut the grid, not sure if thats what I want to do, would be much easier with outside spacer. I would use double build magnet wire, I am not sure about the insulation on this wire, but Mooray knows.

info on line

http://gainclone.com/phpBB2/viewtopic.php?t=681&start=0

http://www.diyhifi.org/forums/viewtopic.php?t=300&postdays=0&postorder=asc&start=0

All the information and possible links that I can provide are posted at either of the above links.

Double build magnet wire has usually got two different material layers inside is mylar and outside top coat nylon.

Using a jig made with a 1/2-20 threaded rod will allow you to string the stator wire to the grid with perfect spacing. The jig needs to be solid so that it does not bend under the stress generated by all the wires. Airplane model glue will works and there is even a non toxic type. This type of glue is a little expensive given the volume necessary. The solvent adhesive I suggested in the links is a better choice.

If you do not plan to ask the panels to operate much below 100 Hz then why make them so wide? I should think that 4-6 inches would be fine and provide much better dispersion as well as a better looking size panel. The wider you make the panels the more directional they will become.

Looks like a really nice project post some pictures as you get it together. Best regards Moray James.

http://gainclone.com/phpBB2/viewtopic.php?t=681&start=0

http://www.diyhifi.org/forums/viewtopic.php?t=300&postdays=0&postorder=asc&start=0

All the information and possible links that I can provide are posted at either of the above links.

Double build magnet wire has usually got two different material layers inside is mylar and outside top coat nylon.

Using a jig made with a 1/2-20 threaded rod will allow you to string the stator wire to the grid with perfect spacing. The jig needs to be solid so that it does not bend under the stress generated by all the wires. Airplane model glue will works and there is even a non toxic type. This type of glue is a little expensive given the volume necessary. The solvent adhesive I suggested in the links is a better choice.

If you do not plan to ask the panels to operate much below 100 Hz then why make them so wide? I should think that 4-6 inches would be fine and provide much better dispersion as well as a better looking size panel. The wider you make the panels the more directional they will become.

Looks like a really nice project post some pictures as you get it together. Best regards Moray James.

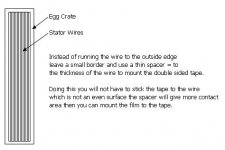

Thanks Moray, I have read those posts before, very good. However I still have a ? If a leave a small border around the outside edge of the egg crate, what would be good to use to bring that part to the same level as the wire before I use the double sided tape. Also if the panels are say 5" wide x 46 will I need any other supports for the film.

looking good

Not sure that I understand why you want to leave a space around the outside edge and then say that you want to clamp the diaphragm in that space. Why not run the resistive coating to just shy of the foam spacers? I think that I must be missing something.

With a diaphragm of 4-6 inches in width I dont think that you will require and spot claming to provide stability to the diaphragm. Since you dont intend the panel to go low you can have lots of tension which will insure stability as well as high output. Looking good so far. Regards Moray James.

Not sure that I understand why you want to leave a space around the outside edge and then say that you want to clamp the diaphragm in that space. Why not run the resistive coating to just shy of the foam spacers? I think that I must be missing something.

With a diaphragm of 4-6 inches in width I dont think that you will require and spot claming to provide stability to the diaphragm. Since you dont intend the panel to go low you can have lots of tension which will insure stability as well as high output. Looking good so far. Regards Moray James.

ok think I understand

So you want to leave a 1/2 inch space around the outside edge of the diaphragm. String the wire to the half inch point and stop. Then either glue you solid plastic spacers of what ever thickness you like to the louver or use your double sided foam core tape as your spacer to your louver. Make the solid spacers or the tape a half inch wide as your louver is half inch squares. Am I on the right page? Regards Moray James. Oh at the top and bottom of the louvre you glur the wires in place and stop short of the spacer and dress the wires in under the spacers.

So you want to leave a 1/2 inch space around the outside edge of the diaphragm. String the wire to the half inch point and stop. Then either glue you solid plastic spacers of what ever thickness you like to the louver or use your double sided foam core tape as your spacer to your louver. Make the solid spacers or the tape a half inch wide as your louver is half inch squares. Am I on the right page? Regards Moray James. Oh at the top and bottom of the louvre you glur the wires in place and stop short of the spacer and dress the wires in under the spacers.

hardware stores

You can find opaque white styrene at hardware stores that sell lighting supplies to go with the cube louvre which is just under a 1/16 of an inch thick. Same material as the louvre, so easy to glue.

With 30 guage wire I would not be too concerned with running the wire right under the spacers as it is at the end of the panel and not impact the spacing enough to worry about but it will increase the shunt capacitance a little. If it's your first set of panels don't fret it as you will probably build more and you can dress the next set better this will get you up and running fast and easy. Regards Moray James.

You can find opaque white styrene at hardware stores that sell lighting supplies to go with the cube louvre which is just under a 1/16 of an inch thick. Same material as the louvre, so easy to glue.

With 30 guage wire I would not be too concerned with running the wire right under the spacers as it is at the end of the panel and not impact the spacing enough to worry about but it will increase the shunt capacitance a little. If it's your first set of panels don't fret it as you will probably build more and you can dress the next set better this will get you up and running fast and easy. Regards Moray James.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- moray james (proposed ESL)