No wood worker here.

Probably been asked and answered a dozen times but that 2mm step off between the baffle and driver I was willing to overlook a few months back is now bugging the hell out of me and want to fix it.

I was doing my first scratch build and was in too damn a hurry to stuff the guts into the enclosure and hear my brainchild--so in cutting the holes just plunged on w/o getting the recess right.

Speakers sound terrific so really a matter of aesthetics at this point. I'm stumped--should I create a new center hole by drilling screw holes through the recess and using some some built up scrap to create a new center that's about flush with the cutting plane so that I can rout the recess deeper or is there some affordable combo of edge guided bits that will allow me to shave a couple of mm deeper. The fit between the woofer and its cutout is good and don't want to widen it too much to get the depth right--to me thats just trading one defect for another.

Appreciate any advice.

Probably been asked and answered a dozen times but that 2mm step off between the baffle and driver I was willing to overlook a few months back is now bugging the hell out of me and want to fix it.

I was doing my first scratch build and was in too damn a hurry to stuff the guts into the enclosure and hear my brainchild--so in cutting the holes just plunged on w/o getting the recess right.

Speakers sound terrific so really a matter of aesthetics at this point. I'm stumped--should I create a new center hole by drilling screw holes through the recess and using some some built up scrap to create a new center that's about flush with the cutting plane so that I can rout the recess deeper or is there some affordable combo of edge guided bits that will allow me to shave a couple of mm deeper. The fit between the woofer and its cutout is good and don't want to widen it too much to get the depth right--to me thats just trading one defect for another.

Appreciate any advice.

I'd stick or screw a 10mm ply board behind it (do you have rear access?) and then iterate the location of the center point using compasses or string and pencil.

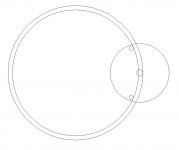

Could you work with something like this?:

Router Bushing Set

I know your depth is not the same as what they are working with but that is the idea.

You could make another board stack to act as a guide for this setup using the router bushing set.

Or make two guide pins on the router base. see jpg

🙂

Router Bushing Set

I know your depth is not the same as what they are working with but that is the idea.

You could make another board stack to act as a guide for this setup using the router bushing set.

Or make two guide pins on the router base. see jpg

🙂

Attachments

Your best ,most accurate bet is to use a bearing guided rabbiting bit,then if its smaller than your rabbit.clean the rest by hand.

2 if depth I'd sufficient, which I doubt use a flush trim bit with the bearing on shank.

They can be had in 1/4 length.

If you need to make a new center and can access the back of the baffle, here's a couple ways to get the center..this wold be my last reort.

Printable instructions for finding the center of a circle with any right angled object

Finding the center of a circle or arc with compass and straightedge or ruler - Math Open Reference

You could also build it up with veneer and turn a flaw into a plus.

Veneer is easy.

2 if depth I'd sufficient, which I doubt use a flush trim bit with the bearing on shank.

They can be had in 1/4 length.

If you need to make a new center and can access the back of the baffle, here's a couple ways to get the center..this wold be my last reort.

Printable instructions for finding the center of a circle with any right angled object

Finding the center of a circle or arc with compass and straightedge or ruler - Math Open Reference

You could also build it up with veneer and turn a flaw into a plus.

Veneer is easy.

Happens all the time. Best is to bolt in a backer board so you do have a center. Now, finding that center is a bit of a challenge.

Some router edge guides have adjustable rollers, but they tend to be not the best.

Some router edge guides have adjustable rollers, but they tend to be not the best.

Be sure to orient the board with an arrow or something or you WILL be off center.

I don't care for bushings. They also have to have the orientation concerns as they tend to be slopped than I like.

I don't care for bushings. They also have to have the orientation concerns as they tend to be slopped than I like.

+1 on that.

The only flush mounting that I would worry about is for the typical 104mm flange tweeter. Even the proud flange of a woofer right next to the tweeter is not really a big deal because the edge is sweeping away.

how about:

- make a pattern jig the diameter of the driver flange,

- mount over the driver still in the enclosure and clamp to enclosure and work bench

- remove driver , stuff enclosure with newspaper or rags to reduce dust/chips

- if you've used threaded inserts or T-nuts for mounting driver remove them now

- use mortising/pattern following bit set to required depth, and one or two quick passes should do the trick

- make a pattern jig the diameter of the driver flange,

- mount over the driver still in the enclosure and clamp to enclosure and work bench

- remove driver , stuff enclosure with newspaper or rags to reduce dust/chips

- if you've used threaded inserts or T-nuts for mounting driver remove them now

- use mortising/pattern following bit set to required depth, and one or two quick passes should do the trick

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- Modifying a round cutout without a center