You are mixing things up. 🙂...and I don't recall any that come with an alnico magnet, either, although someone could correct me if I'm wrong here.

What alnico magnet has to do with it. Unless you are using alnico...

You can always ask it OEM or for special purposes, but is not common, like for GPA, Audio Nirvana or other (nice) cases.

Unless you go back to vintage, today there's more interest in neodymium magnets. The K-series are alnico, the E-series are ferrite. That driver is also 150W only, if you ask me.

http://www.diyaudio.com/forums/full-range/44424-alnico-vs-neodymium.html

You should also be aware of materials like PP, others like sandwich cones types, why not and just worth mentioning Dynaudio's proprietary magnesium silicate polymer (MSP) cone diaphragm.

M Series - The Ultimate Main Monitors

AIR studios, exclusive tour. - YouTube

Scan-Speak, Dynaudio and AudioTechnology corporations, were founded by Mr. Skaaning.

94 dB 15" AudioTechnology Flexunits 15 E 102 25 10

KEF is marketing speakers today using ACE, so they must see enough return on the technique to continue using it.

Seems to me that using a Linkwitz transform on an efficient driver is a better way to achieve low F3 from a Sealed box. No matter how you get low F3, the driver is the only source of sound, so excursion requirements will be the same. With an efficient driver, the power requirements will not be a burden.

I have not noticed any sonic effect from the application of shellac to the cones of my speakers. I do it because I live in a location with high humidity, and I want to keep the cones from absorbing moisture. I like to use "sanding sealer", which is de-waxed shellac, thinned 1 to 1 or so. For heavy woofer cones, sometimes I use 2 coats.

Dynaudio's proprietary magnesium silicate polymer (MSP) cone diaphragm.

I actually built a pair of speakers using Dynaco woofers and, although it was a well behaved driver, found it lacking in detail which was disappointing.

I actually built a pair of speakers using Dynaco woofers and,

although it was a well behaved driver, found it lacking in detail

which was disappointing.

What was the the model of the Dynaudio you were dissapointed with?

Dynaco is a typo?

I am thinking of ordering dewaxed garnet shellac flakes - I have seen where garnet was preferred to the clear stuff for acoustical characteristics, FWIW, by a poster who called himself GregB in Audioasylum.

Last edited:

They were 17W-75Ext woofers.

There are others too who think similar of those series of bassmids.

Usually Dynaudio crosses them pretty low around 2 kHz. I have

a similar driver waiting to be installed in a box, only 4 ohm version

MW 160 GT and with Esotec tweeter I can only say it played excellent

for some time before box went to garage to be painted.

Did you make your own XO filter with measurements or otherwise?

Hi -

I started off taking measurements to develop the basic xover and then tweaked them while listening to the speakers. It was while I was listening and comparing them to a pair of Chartwell LS3/5 A's that I have that I noticed the Dynaudio woofer detail effect on music. I tried a number of things to tweak it out in the xover but nothing worked. It didn't sound like a frequency response issue - more like a low level thickening perhaps due to cone damping. I used a 2khz xover for this design, also.

I started off taking measurements to develop the basic xover and then tweaked them while listening to the speakers. It was while I was listening and comparing them to a pair of Chartwell LS3/5 A's that I have that I noticed the Dynaudio woofer detail effect on music. I tried a number of things to tweak it out in the xover but nothing worked. It didn't sound like a frequency response issue - more like a low level thickening perhaps due to cone damping. I used a 2khz xover for this design, also.

Last edited:

Thoriated,Silicone spray is great for keeping liquid water off the cone, but will not stop gasses (including water vapor) from passing through it to a great extent, from what I've read.

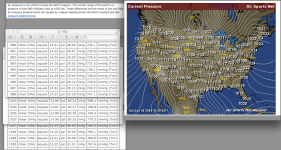

Air pressure (AKA barometric pressure) normally can vary from 980 millibars, which equals 14.21 pounds per square inch to 1050mb which is 15.23psi, a net difference of 1.02psi. Just looking at today's USA current pressure map shows readings from 991mb to 1024mb at one point in time.

An 15" has around 133 square inches of cone area, 133 x 1.02psi= 135.66 pounds, assuming you seal the cabinet in the middle of the barometric range, there is still about a 68 pound pressure swing that can be normally expected, more with extreme storm conditions which seem to be happening with more frequency.

Assuming 68 pounds of pressure on the cone does not actually tear the surround, it can certainly result in an offset great enough that the coil will easily bottom out, as well as the attendant distortion and sensitivity loss of a driver forced to operate with it's coil pushed out of the magnetic gap, whether rearward or forward offset. These are good reasons why "sealed" cabinets are never designed to be "air tight".

Art

Attachments

Last edited:

Nice point Art. As for the shellac, woodworkers use it for everything except maybe the final coat. It's edible, so it must be audible, right? Wrong?? I'd expect it to stiffen the cone somewhat, so you might apply it in steps to induce a fragmented breakup behavior, like one coat on the entire cone, a second on two thirds, a third on the first third from the voice coil. I wouldn't rule out modern acrylics; that's what I topcoat with.

Hi-

I don't hope to make the box completely air tight - what I'm hoping to accomplish is to reduce the infiltration of water vapor to an amount that might be expected if the woofers actually did have polypropylene cones. The side benefit of this is that the woofers would be largely immune to external humidity changes. That should also increase the time that the desiccant perhaps should be replaced to maintain a low internal humidity. But I haven't run any numbers on this yet.

Phivates - you raise a good point, and that may be the sort of thing I wind up doing. I have a test 15" guitar speaker with a similar cone profile to that of the E145 and I may see first how far a gram of the shellac goes toward covering it, and judge what effect it may have sonically.

This GregB that I mentioned wrote that he liked the sonic effect of garnet shellac but was ambivalent on the effects of more purified shellac and didn't like the effect or acrylic finishes on speaker cones which he described as 'too plasticky'. Of course this is highly subjective. Do I understand what he wrote the way he intended? Do I hear similarly enough to him to receive similar impressions as he described? Would the K/E 145 benefit from the effects of the cone treatment the way I hope which would be primarily related to anomalies below 500 hz? In this thread, GregB wrote that he believed that a 2226 would benefit from such a treatment. Overall, given the opportunity to reduce RH infiltration at the same time, it sounds like it might be worth the risk. I could start by not covering the center dome with shellac which would be less likely to effect the ultimate HF rolloff of the speaker, or by using the butyl rubber there as an offset, perhaps.

I don't hope to make the box completely air tight - what I'm hoping to accomplish is to reduce the infiltration of water vapor to an amount that might be expected if the woofers actually did have polypropylene cones. The side benefit of this is that the woofers would be largely immune to external humidity changes. That should also increase the time that the desiccant perhaps should be replaced to maintain a low internal humidity. But I haven't run any numbers on this yet.

Phivates - you raise a good point, and that may be the sort of thing I wind up doing. I have a test 15" guitar speaker with a similar cone profile to that of the E145 and I may see first how far a gram of the shellac goes toward covering it, and judge what effect it may have sonically.

This GregB that I mentioned wrote that he liked the sonic effect of garnet shellac but was ambivalent on the effects of more purified shellac and didn't like the effect or acrylic finishes on speaker cones which he described as 'too plasticky'. Of course this is highly subjective. Do I understand what he wrote the way he intended? Do I hear similarly enough to him to receive similar impressions as he described? Would the K/E 145 benefit from the effects of the cone treatment the way I hope which would be primarily related to anomalies below 500 hz? In this thread, GregB wrote that he believed that a 2226 would benefit from such a treatment. Overall, given the opportunity to reduce RH infiltration at the same time, it sounds like it might be worth the risk. I could start by not covering the center dome with shellac which would be less likely to effect the ultimate HF rolloff of the speaker, or by using the butyl rubber there as an offset, perhaps.

Last edited:

I'm thinking that if you mix your shellac yourself then the weight of the flakes before mixing with the alcohol should be useful in determining the mass you're adding to the cone. As a long time cone doper I can tell you that too much is way too much.

Have some covers made like granma had on her sofa back in the '50's. Use 'em when you're not listening to muzak.

Last edited:

Here I'm attaching a photo of the Le Cleach horn flare that I plan to use to cast the oval concrete horns from. Not visible in this photo is that there is a small mouth flare curvature to avoid a discontinuity with the front flat portion of the horn. The horn and driver attachments and external horn mold forms are not made yet.

Attachments

Last edited:

...Would the K/E 145 benefit from the effects of the cone treatment the way I hope which would be primarily related to anomalies below 500 hz?..

I hope you are aware that JBL does not make any more replacement cones for the K/E145 speakers and the old stocks are finished.

Pretty much a disaster if it works badly, it would be a pity to lose 4 nice speakers with no close modern equivalent, if not exactly irreplaceable.

Best wishes

David

I've used Visaton LTS 50 (black) to seal paper cones using only 1 light coat. Unlike PVA etc, it doesn't stiffen the cone and flexibility remains. I've used it on 830875, 18W8531G00 and SB15NRXC30-8.

Any benefits to sound is subjective, so won't comment other than there appears to be no detriment to the sound.

Any benefits to sound is subjective, so won't comment other than there appears to be no detriment to the sound.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Minimum mass moisture sealant for speaker