On my biscuit boxes I found different types of open-cell foam in different layers on the back wall, with cotton wool filling the rest of the space worked well, but I generally try to make the enclosure so it tapers. If you had the distance from the cone to the rear of the box so short that the shortest wavelength wouldn't be able to reflect (possibly true of the BBC LS35a) surely stuffing wouldn't be needed?

Using something better than Minidsp DACs will be a larger upgrade than finding the correct thickness of rear wall stuffing for the midrange.The crossover is a MiniDSP digital crossover so the driver free air mechanical resonance does not affect the crossover filter parameter settings.

-it alters driver compliance with a bit of a "delay" added-in.How come may i ask?

Read through this small thread on a post about this I did sometime ago:

https://www.diyaudio.com/community/threads/my-fostex-fe-108ez-project-part-2.75940/

Note: it is however dependent on the driver - drivers with stiff suspensions or heavily damped surrounds tend to display this far less than other drivers.

Stuffing itself isn't bad if it's placed properly in the loudspeaker, notably it should be OFF of the interior walls with enough air-space near the walls and driver (a couple of inches or more) to not "slow down" the driver's movement.

The miniDSP engine is used only for crossover functions. The A/D and D/A is done externally with a studio grade 8-channel ADC/DAC.Using something better than Minidsp DACs will be a larger upgrade than finding the correct thickness of rear wall stuffing for the midrange.

The best location is quarter a wavelength away from walls where the particle velocity is highest and squeezing air through/around fibres meets most resistance leading to the most energy dissipation. Another reason for a relatively large volume.

1/4 wavelength of what frequency? The mid-range may be reproducing a range 100 Hz-4 kHz.

B&W, Vivid make cutting edge products that include highly developed mid-range driver/enclosure technology.If you follow the approach of a relatively large volume, light stuffing near the driver, denser further away with plenty away from the walls then the effectiveness of the type of stuffing becomes fairly unimportant as does geometry detail in most cases. Without significant design constraints (e.g. only having a tiny volume available) it is rarely an area requiring much design effort which is likely the reason you have found relatively little on the topic.

The stuffing for a sealed woofer enclosure would seem to be for control of the principal internal air resonance which can be modelled by air mass and effective compliance of the combined drive/air compliance. This is essentially a lumped parameter model. In practice there are higher modes but they are relatively lower order artefacts. There is the standard test of increasing the stuffing while monitoring the driver impedance rise at resonance.

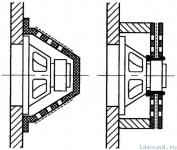

The mid-range is different in that the shorter wavelengths allow fully developed wave motion to propagate within the enclosure. This may be the reason why B&W, Vivid etc, developed mid-range driver/enclosures that allow the rear waves to propagate into a geometry that attenuates them. I am speculating that the geometry and stuffing of the rear enclosure can produce superior damping of the mid-range rear wave. Up till now i just do what most others have done, fibre-glass teased out to what seems about right.

1/4 wavelength of what frequency? The mid-range may be reproducing a range 100 Hz-4 kHz.

It is a widely used rule of thumb for the minimum depth of (appropriate) material required to absorb most of the sound. It applies to all audible frequencies which is why anechoic chambers seeking to absorb frequencies down to 50 Hz have 2 metre deep wedges (triangular in shape in order change the impedance gradually) whereas the absorbing material in a tweeter chamber seeking to absorb frequencies in the kHz range are typically less than an inch.

B&W, Vivid make cutting edge products that include highly developed mid-range driver/enclosure technology.

Cutting edge? Both companies sell very expensive luxury goods which require marketing features to distinguish them from the competition. The fancy midrange chambers have effectively zero engineering purpose but can add genuine value in the eyes of customers that lack the relevant engineering knowledge. Pretty much all expensive luxury goods in all fields do this and so is not intended as a criticism but more an observation on how value and marketing works for expensive luxury goods.

If we want a more reliable indication of what is required in terms of engineering (without learning the engineering) looking at examples from the large established manufacturers of professional speakers (e.g. Genelec, Neumann,...) is going to be wiser because technical sound quality has some relevance in being commercially successful. How much is debatable but at least it has some significance in a way it often doesn't with very expensive home audio speakers.

The mid-range is different in that the shorter wavelengths allow fully developed wave motion to propagate within the enclosure. This may be the reason why B&W, Vivid etc, developed mid-range driver/enclosures that allow the rear waves to propagate into a geometry that attenuates them. I am speculating that the geometry and stuffing of the rear enclosure can produce superior damping of the mid-range rear wave. Up till now i just do what most others have done, fibre-glass teased out to what seems about right.

Assuming it makes a significant difference to the technical performance why do you think so few other speaker manufacturers fail to do likewise? The cost would be low and manufacture straightforward particularly for lower price speakers produced in volume and hence more able to absorb tooling costs.

It all depends on the size of the enclosure. If the largest internal dimension is smaller than half the smallest wavelength you want to reproduce, no internal standing waves can be set up by the driver.

In that case, no damping material is required. However, please take note that drivers also reproduce outside the crossover frequency, so standing waves well above the crossover frequency have to be damped. Plus, there are noises and harmonics being produced at the rear side of the driver that also have to be considered.

In that case, no damping material is required. However, please take note that drivers also reproduce outside the crossover frequency, so standing waves well above the crossover frequency have to be damped. Plus, there are noises and harmonics being produced at the rear side of the driver that also have to be considered.

My takle on stuffing midrange enclosures including implicit responses to some posts above:

1/4 wave length is indeed the cut off frequency in anechoic rooms (and for absorbing material in general), but below that frequency it still absorbs yet decreasing with frequency.

My experience dates back some 40+ years.

An enclosure acoustically behaves like any other enclosed space whatever its size or shape.

What we aimed for was it to be as dead(acoustically ;-)) as possible, and ended up with filling it with irregular shaped and sized flakes of wool, of very shorthaired wool, and thoroughly cleaned (See photo)

, with a weight of 20-25gr per liter. Especially for woofers an additional damping occured due to the pinecone structure of a wool fibre. This microscoping structure opened / closed under pressure variations, thus absorbing energy. Note we worked with sealed boxes only.

, with a weight of 20-25gr per liter. Especially for woofers an additional damping occured due to the pinecone structure of a wool fibre. This microscoping structure opened / closed under pressure variations, thus absorbing energy. Note we worked with sealed boxes only.

We bought that wool in big compressed packs of 200 or more kilograms, and once the steel bands holding it together were removed it expanded quite a bit ;-)

Lots of experiments done before reaching this.

The absorbing material to choose makes a difference, depending on its spatial structure and in case of blankets how it is bonded.

F.e. At that time BAF ( bonded acetate fibre) was often used. But its absorbing behavior was reasonable when acoustically loaded on the edges and quite poor on its flat sides, due to the way it was bonded. All in all is was not very effective in deadening the cavity.

Baileys long hair wool , or carded short-hair wool showed some significant lack of damping in the direction of the carding, thus resonances , thus cavity not being 'dead'.

Also combinations of BAF on the backplane and remainder filled with wool failed as the cavity became very 'alive'. So essentially fully filled, with close to the driver somewhat thin to aid the acoustic energy getting into the absorbing matter. But no open spaces in the filling. And the filling being completely irregular in structure and densities.

Music is a pressure variation of some shape and duration, which can be seen as composed out of a number of sinus frequencies. Even for frequencies below the standing wave ones it is still putting energy in an 'alive' enclosed space, so it will trigger resonances/standing waves anyhow. So the driver-enclosure resonance frequency is in scope as well, and a low Qts helps in reducing cone movements. Also the alive cavity would draw the hearing attention to its presence, thus sound will not become disconnected from the speakers.

At that time i was also present at a music recording session held in an anechoic room (a guitar player of the The Hague Recidence orchestra) . Later on this recording was played back on speakers in a room. The difference was striking, how much the room added to the music.

During a design of an 3-way we were looking for a broadband midrange of 4-5 inch, the Fostex fe108 was one of the tested drivers , however showed a sort of collapsing of the rim (outer edge) of the cone as well as the corrugated surround basically being too stiff or too large for the rim of the cone, thus additional loading of the rim mechanically. So any impedance increase on the back side would amplify this problem.

Once this collapsing had occured it would start to collapse gradually at lower and lower power, therefore useless for us. Similar with a Seas midrange, and basically any trumpet like shallow paper cone we tested at that time. Only straight paper cones did not give this collapse, but then the breakup was severe and always started around 1.5-2kHz, well within the higher half of midrange frequencies. (Note we specifically looked for shallow cones to prevent the typical "shouty" character of deeper cones) . So we treated the cones to make them useful, with a special very thin 3 layer CLD coating..

Note that during our search we also observed that for midrange the cone material should be as thin as possible (which is why we looked and these Fostex and Seas drivers), in order to hear also the fine details like f.i. the subtle ambient (hall) sound in te recording.

As a final note: The last systems we produced used the first midrange of Accuton, then called Thiel c2-77

Its capability to reproduce those small detail in sounds was by far the best we found, and broadband as well.

1/4 wave length is indeed the cut off frequency in anechoic rooms (and for absorbing material in general), but below that frequency it still absorbs yet decreasing with frequency.

My experience dates back some 40+ years.

An enclosure acoustically behaves like any other enclosed space whatever its size or shape.

What we aimed for was it to be as dead(acoustically ;-)) as possible, and ended up with filling it with irregular shaped and sized flakes of wool, of very shorthaired wool, and thoroughly cleaned (See photo)

We bought that wool in big compressed packs of 200 or more kilograms, and once the steel bands holding it together were removed it expanded quite a bit ;-)

Lots of experiments done before reaching this.

The absorbing material to choose makes a difference, depending on its spatial structure and in case of blankets how it is bonded.

F.e. At that time BAF ( bonded acetate fibre) was often used. But its absorbing behavior was reasonable when acoustically loaded on the edges and quite poor on its flat sides, due to the way it was bonded. All in all is was not very effective in deadening the cavity.

Baileys long hair wool , or carded short-hair wool showed some significant lack of damping in the direction of the carding, thus resonances , thus cavity not being 'dead'.

Also combinations of BAF on the backplane and remainder filled with wool failed as the cavity became very 'alive'. So essentially fully filled, with close to the driver somewhat thin to aid the acoustic energy getting into the absorbing matter. But no open spaces in the filling. And the filling being completely irregular in structure and densities.

Music is a pressure variation of some shape and duration, which can be seen as composed out of a number of sinus frequencies. Even for frequencies below the standing wave ones it is still putting energy in an 'alive' enclosed space, so it will trigger resonances/standing waves anyhow. So the driver-enclosure resonance frequency is in scope as well, and a low Qts helps in reducing cone movements. Also the alive cavity would draw the hearing attention to its presence, thus sound will not become disconnected from the speakers.

At that time i was also present at a music recording session held in an anechoic room (a guitar player of the The Hague Recidence orchestra) . Later on this recording was played back on speakers in a room. The difference was striking, how much the room added to the music.

During a design of an 3-way we were looking for a broadband midrange of 4-5 inch, the Fostex fe108 was one of the tested drivers , however showed a sort of collapsing of the rim (outer edge) of the cone as well as the corrugated surround basically being too stiff or too large for the rim of the cone, thus additional loading of the rim mechanically. So any impedance increase on the back side would amplify this problem.

Once this collapsing had occured it would start to collapse gradually at lower and lower power, therefore useless for us. Similar with a Seas midrange, and basically any trumpet like shallow paper cone we tested at that time. Only straight paper cones did not give this collapse, but then the breakup was severe and always started around 1.5-2kHz, well within the higher half of midrange frequencies. (Note we specifically looked for shallow cones to prevent the typical "shouty" character of deeper cones) . So we treated the cones to make them useful, with a special very thin 3 layer CLD coating..

Note that during our search we also observed that for midrange the cone material should be as thin as possible (which is why we looked and these Fostex and Seas drivers), in order to hear also the fine details like f.i. the subtle ambient (hall) sound in te recording.

As a final note: The last systems we produced used the first midrange of Accuton, then called Thiel c2-77

Its capability to reproduce those small detail in sounds was by far the best we found, and broadband as well.

I am well into a 3 way build now and I am worried because my mid box seems to have a nasty resonance right in the band I want to use , I judge around 300- 400hz. (I stick my mouth near the opening and kind of sing a sliding scale, It looks like am mad I know, but you can hear instantly if there are any resonances) any way the box is a nice trapezoid shape, with felt lining and even a bitumen rubber paint on the walls to reduce resonance but alas, I still need to tame this spike. I have yet to stuff it with wool which hopefully will help. I read somewhere that hemp fibre is excellent for sound absorbtion. Has anybody come across this before. ? or have any suggestions. Thanks

Lining the walls has the least effect, as particle velocity approaches zero. The most effective placement is in the open volume of an enclosure.Why do you need to stuff a sealed midrange enclosure? Wouldn't just lining the inside with felt or similar to stop cone reflections be enough?

jeff

Hmmm, will also introduce reflections back to the cone.The acoustic impedance panel helps to reduce the mechanical quality factor of the speaker.

I find that baffling right behind the driver with concave panels of PU foam (suspended without backing) can work wonders in less than optimal shaped enclosures. The best shape of mid enclosure is almost always a tapered design with progressively increasing density of damping material. Lining the walls only reduces direct reflecting waves but doesn't do much to absorb longer wavelengths as much as spacing the dampening material from surfaces.

Mids with thin light weight cones don't reject reflections very well and allow them to leak back out of the driver. That's why its important to back cut the baffle edge and keep side walls out of close proximity to the driver. Undampened corners sharper than 90 degrees close to the driver are bad. All panel surfaces right by the driver should reflect sound away from the rear of the driver. That would make a tear drop shaped enclosure the best option for the most inert sound possible from a sealed mid enclosure. Softening 90 degree corners with 45 degree bevels help alot and also help to strengthen the enclosure itself.

Enclosure volume should be large enough to keep Qtc under 0.9-1.0 and ideally keep the HP xover at least an octave above above Fb. HP slopes steeper than 12 dB are very sensitive to the Fb impedance peak and will cause bumps in the summed response, caused by both the impedance and phase variations.

Mids with thin light weight cones don't reject reflections very well and allow them to leak back out of the driver. That's why its important to back cut the baffle edge and keep side walls out of close proximity to the driver. Undampened corners sharper than 90 degrees close to the driver are bad. All panel surfaces right by the driver should reflect sound away from the rear of the driver. That would make a tear drop shaped enclosure the best option for the most inert sound possible from a sealed mid enclosure. Softening 90 degree corners with 45 degree bevels help alot and also help to strengthen the enclosure itself.

Enclosure volume should be large enough to keep Qtc under 0.9-1.0 and ideally keep the HP xover at least an octave above above Fb. HP slopes steeper than 12 dB are very sensitive to the Fb impedance peak and will cause bumps in the summed response, caused by both the impedance and phase variations.

melamine foam...I find polyester batting to be useful to hold other stuffing in place. In the USA, "batting" is a loose, non-woven cloth-like material that would be used inside a quilt blanket. It comes in a roll rather than as loose fibers. It might have a different name in other regions.

A single layer of batting can hold loose rockwool, shredded denim, or wool in place, and keep it out of the driver voice coil gap.

I should also mention melamine foam as a very good absorption media.

do you have a good source to find? I cant quite get any at any reasonable price!

1 шт. Magic Gronge Eraser Cleaner Melamine Foam Cleanermelamine foam...

https://www.amazon.com/USMYTHA-Melamine-Cleaning-Multi-Functional-10x6x2CM/dp/B00XC32NMK

Attachments

Kitchen (kitchen supplies store)))do you have a good source to find?

The melamine foam for acoustic application i know of is basotect and/ or flamex.

Both are not usable for kitchen cleaning. Too brittle.

Both are not usable for kitchen cleaning. Too brittle.

Last edited:

I have never utilized melamine foam, but others speak highly of it. @HeadShake found an online source for melamine acoustic foam, and another member suggested buying melamine cleaning foam sponges in bulk, as they are significantly cheaper to buy in bulk.

j

j

The melamine foam for acoustic application i know of is basotect and/ or flamex.

Both are not usable for kitchen cleaning. Too brittle.

can we use the melamine foam meant for kitchen application or their acoustic properties are altered?I have never utilized melamine foam, but others speak highly of it. @HeadShake found an online source for melamine acoustic foam, and another member suggested buying melamine cleaning foam sponges in bulk, as they are significantly cheaper to buy in bulk.

j

- Home

- Loudspeakers

- Multi-Way

- Mid-range driver enclosure stuffing