Please help...

I just "found" a RX 1500 w/ Rega-arm, and it needs a little attention.

And maybe some "tweaks".

My own suggestions: New PSU, and make a groove on the lower part of platter to hold a thick O-ring (damping). ???

Other suggestions?

Arne K

I just "found" a RX 1500 w/ Rega-arm, and it needs a little attention.

And maybe some "tweaks".

My own suggestions: New PSU, and make a groove on the lower part of platter to hold a thick O-ring (damping). ???

Other suggestions?

Arne K

If you do any tweaks, please report on your findings. But its not the easiest table to remove the platter from. The manual would be helpful for this task, and if you don't have the manual, I believe it is downloadable at Vinyl Engine.

Very easy...

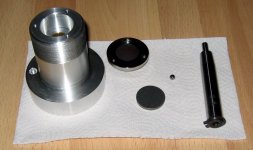

It is similar to this (picture), with alu-platter.

Had a look at motor & psu, and revised my plan to re-new all el-caps. And a filtered IEC plug.

Next step here would be a all new motor-unit...?

For the platter; I will have to check with my friend which is a magician on the lathe...

Arne K

It is similar to this (picture), with alu-platter.

Had a look at motor & psu, and revised my plan to re-new all el-caps. And a filtered IEC plug.

Next step here would be a all new motor-unit...?

For the platter; I will have to check with my friend which is a magician on the lathe...

Arne K

Attachments

About $ 350+ = "cannot resist" - price.

Condition: worn, but not bad...and modified by an amateur...

Luckily it seems that the mods are easy to rectify, (in the process).

Arne K

(Can resist ANYTHING! (-but temptations)).

Condition: worn, but not bad...and modified by an amateur...

Luckily it seems that the mods are easy to rectify, (in the process).

Arne K

(Can resist ANYTHING! (-but temptations)).

I have modded this platter as I had a spare for my Rx1500. The standard aluminium piece is a bit resonant so I added a layer of lead underneathand then filled the remaining cavity with plaster of paris. Depending on how carefull you are, the balance may need correcting although its not absolutely critical at these slow rotational speeds. The effect was good - firming up the soundstage and increasing the dynamic range by virtue of a quieter background.

I also have a plinth wieght that bolts to the underside of the plinth casting. However its not fitted at the moment as I dont think it will be compatible with the standard suspension springs. I need to source some heavier springs to maintain the system frequency.

Colin A.

I also have a plinth wieght that bolts to the underside of the plinth casting. However its not fitted at the moment as I dont think it will be compatible with the standard suspension springs. I need to source some heavier springs to maintain the system frequency.

Colin A.

Progress...

My M-S have now been in "atoms", and rebuit, working perfectly.

Damper-feet have been greased with new silicon-grease(Molykote-111), main-bearing has been cleaned and refilled w. Mobil 1 synthetic automatic trans-fluid.

When giving the platter a slow hand-spin, it runs for several minutes!

Next step: platter...

Somewhere I had a nice formula for making a strobe, but cannot find it, can somebody please suggest how many marks on a given diameter I need? (50Hz)

(Planning to machine small marks on lower edge of platter)

Arne K

My M-S have now been in "atoms", and rebuit, working perfectly.

Damper-feet have been greased with new silicon-grease(Molykote-111), main-bearing has been cleaned and refilled w. Mobil 1 synthetic automatic trans-fluid.

When giving the platter a slow hand-spin, it runs for several minutes!

Next step: platter...

Somewhere I had a nice formula for making a strobe, but cannot find it, can somebody please suggest how many marks on a given diameter I need? (50Hz)

(Planning to machine small marks on lower edge of platter)

Arne K

Re: Progress...

SDS Labs has a downloadeable strobe for 50 & 60 Hz.

dave

Cobra2 said:Next step: platter...

Somewhere I had a nice formula for making a strobe, but cannot find it, can somebody please suggest how many marks on a given diameter I need? (50Hz)

(Planning to machine small marks on lower edge of platter)

SDS Labs has a downloadeable strobe for 50 & 60 Hz.

dave

If you go to the Theres pages, you will find that they use extremely thick oil for the bearing (which appears to be the same principle as yours).

Perhaps you should consider doing the same ... The idea appears to be better damping - the added friction is apparently an advantage. Might reduce the number of minutes turning though ...

Petter

Perhaps you should consider doing the same ... The idea appears to be better damping - the added friction is apparently an advantage. Might reduce the number of minutes turning though ...

Petter

About oil...

I have also seen this at Teres...but I do not think the Teres-bearing have the same fine tolerance as Micro Seiki.

The Teres also have a speed-checking strobe to control the motor-speed.

And reason for ATF fluid, is that it is usually less aggresive than gear-oils, and have less useless additives than motor-oils.

(could talk oil & fuel & engine-tuning all day long....).

Arne K

I have also seen this at Teres...but I do not think the Teres-bearing have the same fine tolerance as Micro Seiki.

The Teres also have a speed-checking strobe to control the motor-speed.

And reason for ATF fluid, is that it is usually less aggresive than gear-oils, and have less useless additives than motor-oils.

(could talk oil & fuel & engine-tuning all day long....).

Arne K

I have also seen this at Teres...but I do not think the Teres-bearing have the same fine tolerance as Micro Seiki.

think you'll find the Teres/Redpoint/Galibier bearings have finer tolerances than the MS. Teres does't use "thick" oil to take up the slack and Galibier/Redpoint use thin oils.

the Teres bearing can take a few hours to a day to sink properly into the bearing so fine are the tolerances.

I assembled the bearing dry-wiped, (but not de-greased), and could not get the AIR out!!!😱

That is a tight fit in my book....

Anyway, my main point was; Teres have speed-feedback,

Micro Seiki has not.

But, if it does not work, I will try your suggestions.

ArneK

That is a tight fit in my book....

Anyway, my main point was; Teres have speed-feedback,

Micro Seiki has not.

But, if it does not work, I will try your suggestions.

ArneK

check the Teres site for instructions on how to fill their bearing and it might help you in getting the bearing seated. It needs to be degreased before assembly otherwise it may not seat properly.

No problem

Under the label that tells you ; "This bearing is hermetical sealed", there is a vent-screw with o-ring.

Under the label that tells you ; "This bearing is hermetical sealed", there is a vent-screw with o-ring.

Arne K

Under the label that tells you ; "This bearing is hermetical sealed", there is a vent-screw with o-ring.

Under the label that tells you ; "This bearing is hermetical sealed", there is a vent-screw with o-ring.

Arne K

wrong No of bands on Strobe...

Hi,

These 2 strobes shown in the above mentioned pdf file have a very practical diameter because you can stick it on your record clamp and have your speed monitored all the time (with the record playing I mean, which is very important...)

Problem is that the number of bands are half of what they should be...

To my knowledge:

Cheers

Hi,

These 2 strobes shown in the above mentioned pdf file have a very practical diameter because you can stick it on your record clamp and have your speed monitored all the time (with the record playing I mean, which is very important...)

Problem is that the number of bands are half of what they should be...

To my knowledge:

- for 50 Hz you need: 180 bands for 33.33rpm and 133.33 bands for 45rpm.

for 60 Hz you need: 216 bands for 33.33rpm and 160 bands for 45rpm.

Cheers

Bearing, see:

http://www.diyaudio.com/forums/showthread.php?postid=257314#post257314

Petter, please e-mail me! ( cobra2 at online dot no )

Arne K

http://www.diyaudio.com/forums/showthread.php?postid=257314#post257314

Petter, please e-mail me! ( cobra2 at online dot no )

Arne K

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Micro Seiki 1500