I would say those vibrations of the loudspeaker at 7.5 kHz are pretty much concentric and hence tangential. If this is what happens with the metal cones, a few strips of fibreglass going radially from the VC former to the surround should be able to surpress them. On the other hand, it is hard to see how the rubber band around the edge of the membrane that Jonathan Carr mentioned would help.

Yes, the 1.0, 1.78, and 7.5 kHz vibrations are all clearly tangential, though I don't see a strong resonance in the 1.0 kHz vibration. If the cone of a particular driver has a curvature to the diaphram, then I would expect in general for tangential modes to be lower than radial modes. What is interesting is that it appears the tested driver had a rather flat diaphram.

The diy'er should be careful of making driver modifications without means to test the result, however. If adding radial strips to increase the first tangential mode frequency was a clear solution without substantial negatives, it would be a simple matter to add a stamping process to the driver manufacturing line which adds radial ridges to the cone.

Was that process left out because another $2 per driver retail cost was unacceptable, or because the addition of stiffening ridges had unacceptable negative consequences?

The diy'er should be careful of making driver modifications without means to test the result, however. If adding radial strips to increase the first tangential mode frequency was a clear solution without substantial negatives, it would be a simple matter to add a stamping process to the driver manufacturing line which adds radial ridges to the cone.

Was that process left out because another $2 per driver retail cost was unacceptable, or because the addition of stiffening ridges had unacceptable negative consequences?

I know this is kind of the opposite, but don't Scan Speak sell a little mid-bass driver with slits cut radially/slanted?add a stamping process to the driver manufacturing line which adds radial ridges to the cone.

I think it is used in some commercial speakers, and is meant to be decent. Could these slits be to control resonance in some way?

-Simon

"I think it is used in some commercial speakers, and is meant to be decent. Could these slits be to control resonance in some way?"

Absolutely correct on all points.

/Peter

Absolutely correct on all points.

/Peter

I use the 50mm (2") Bandor full-range drivers and my measurements indicate a resonance at about 16kHz. I use C37 lacquer to give a better subjective sound above the cone break-up modes.

C37 has a reputation for being expensive but, even using three coats (it's extremely light) very little is needed to treat aluminium cones as it coats the surface but doesn't sink into the material.

Doreen of Bandor has used a rubberish gloop to treat troublesome cone resonances (such as when we tried a black anodising process instead of the more usual gold). I prefer the C37.

C37 has a reputation for being expensive but, even using three coats (it's extremely light) very little is needed to treat aluminium cones as it coats the surface but doesn't sink into the material.

Doreen of Bandor has used a rubberish gloop to treat troublesome cone resonances (such as when we tried a black anodising process instead of the more usual gold). I prefer the C37.

Rubber cement. As it comes from the bottle, it's too thick to spread evenly, so you need to dilute it. It's dead. It doesn't crack. It's cheap. It's readily available. Good stuff for experimentation purposes.

No, I've never tried it on metal cones. The only one I've got is the aluminum one in my Hartke cabinet, and I like it just fine the way it is.

Keep in mind that no matter what you put on the cone, you're adding mass. The T-S parameters will change accordingly.

Grey

Hello

What did you used to thin the Rubber cement ?

Thank

Bye

Gaetan

Are we talking ½oz/yd stuff thin, if yes you can use Minwax polyurethane water based varnish. Use this combination for building ultra light weight R/C aircraft wing skins. Best to vacuum bag it when done for best contact/removal of trapped air bubbles.Interesting comments so far!

Maybe I didn't make myself clear enough because nobody's yet picked up on it: I don't want to put some sticky coat on the cone, I was thinking about laminating pieces of fibreglass (or paper) to the back side). I have very thin fibreglass mats that would add close to no weight. With some lightweight glue (wallpaper glue), the change in mms would be minimal. At the same time, I assume the bending stiffness would improve locally where a piece of fibreglass is attached. Therefore, it is important to know the shape of the resonant modes.

The gue thing has been done: Audio International have a special version of the W17 made for them which has a reddish paint rather than the gray stuff. Mms is almost unchanged (maybe + 1 g), but resonances are not as severe.

Should see what can be made from some carbon rod/tubing, bluecore sheathing foam and either glass or carbon fabric. In aircraft design weight is drag, heavier the plane more energy is expended to lift which creates drag. Amazing to see a 400 speed (think motor 1"dx1.4"l) pylon plane do >130knts, races last 90 seconds. You have no nerves left to fly longer 😉

polyurethane isn't waterbased

ps I don't think u shd put any water based product near aluminium unless its already coated

ps I don't think u shd put any water based product near aluminium unless its already coated

I've tried many things to tame metal cone resonances. Nothing worked well. Damping material and cone slits do almost nothing to a metal. Here is one of my old tests.

TwisterSpeakers: aluminum woofers' cone treatment experiment

It's better to avoid using metal drivers altogether. The relatively effective modification would be making radial extrusions of the metal cone. Something like this

TwisterSpeakers: aluminum woofers' cone treatment experiment

It's better to avoid using metal drivers altogether. The relatively effective modification would be making radial extrusions of the metal cone. Something like this

An externally hosted image should be here but it was not working when we last tested it.

I've tried many things to tame metal cone resonances. Nothing worked well. Damping material and cone slits do almost nothing to a metal. Here is one of my old tests.

TwisterSpeakers: aluminum woofers' cone treatment experiment

It's better to avoid using metal drivers altogether. The relatively effective modification would be making radial extrusions of the metal cone. Something like this

An externally hosted image should be here but it was not working when we last tested it.

Have you tried annealing the metal radially like in your pic?

polyurethane isn't waterbased

ps I don't think u shd put any water based product near aluminium unless its already coated

Minwax Water Based Oil-ModifiedPolyurethane - Interior Clear Protective Finishes - Minwax

Minwax Minwax : Int W/B Gls Polyurethane - Tools - Painting & Supplies - Stains

But yes I did misspeak, had to grab a can and find a link. It's Minwax Polycrylic clear satin water based.

Minwax Polycrylic Protective Finish - Interior Clear Protective Finishes - Minwax

And what harm is water going to bring to an aluminum cone? Without impurities there is no galvanic action which could only occur while still wet. Kinda like saying not to put a clear protective sealer on AL because it'll do more harm than good? If it's anodized surface conductance go way up and is sealed by migration of sulfur ions into the metal increasing the surface tension hardening it. Like pots and pans...

Last edited:

An old thread revisted!

Dr Klippel and Dr. Larsen have studied these issues comprehensively and are real gurus in the field with their own companies, consutling major loudspeaker manufacturers.

A nice demo about driver cone design by Loudsoft (Larsen) FINECone demo video and presentation at 51st AES http://www.loudsoft.com/images/pdf_filer/ADWL_Active%20Loudspeakers_LOUDSOFT.pdf

A nice poster about cone issues by Klippel http://www.klippel.de/fileadmin/kli...ure/Papers/KLIPPEL_Sound_Radiation_Poster.pdf

and about speaker directivity http://www.klippel.de/fileadmin/kli...ture/Papers/KLIPPEL_Cone_Vibration_Poster.pdf

Dr Klippel and Dr. Larsen have studied these issues comprehensively and are real gurus in the field with their own companies, consutling major loudspeaker manufacturers.

A nice demo about driver cone design by Loudsoft (Larsen) FINECone demo video and presentation at 51st AES http://www.loudsoft.com/images/pdf_filer/ADWL_Active%20Loudspeakers_LOUDSOFT.pdf

A nice poster about cone issues by Klippel http://www.klippel.de/fileadmin/kli...ure/Papers/KLIPPEL_Sound_Radiation_Poster.pdf

and about speaker directivity http://www.klippel.de/fileadmin/kli...ture/Papers/KLIPPEL_Cone_Vibration_Poster.pdf

Last edited:

I think this is right direction in cone design

The Madisound Speaker Store

I recently finished listening test with metal drivers with breakup peak 35db down. after several days of listening at moderate levels I had to unplug the speakers. listening to music had turned into an unpleasant experience. The bad thing about metal, its resonances are not immediately apparent, they grow on you over time. Initially one can get an impression of a nice clean sound.

The Madisound Speaker Store

I recently finished listening test with metal drivers with breakup peak 35db down. after several days of listening at moderate levels I had to unplug the speakers. listening to music had turned into an unpleasant experience. The bad thing about metal, its resonances are not immediately apparent, they grow on you over time. Initially one can get an impression of a nice clean sound.

metal sure loses some rigidity over stress and time, but I guess it is mostly surround and spider changes..

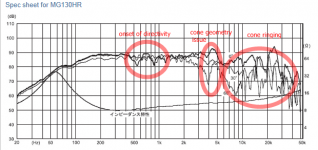

The 600-400$ Fostex has a very interesting shape of cone. But it still has some typical irregularites. Some come from acoustic interferences (based on dimensions, like the onset and continuity of directivity) and some are mechanical, from cone, surround etc (ringing, sharp peaks). What really hits my eyes is the wobbles in directivity, a very peculiar behaviour. Is this good or bad behaviour?

Another example is Accuton C90

The 600-400$ Fostex has a very interesting shape of cone. But it still has some typical irregularites. Some come from acoustic interferences (based on dimensions, like the onset and continuity of directivity) and some are mechanical, from cone, surround etc (ringing, sharp peaks). What really hits my eyes is the wobbles in directivity, a very peculiar behaviour. Is this good or bad behaviour?

Another example is Accuton C90

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- metal cone resonances, what direction, how to suppress?