Did you short the non-tested section?

A very big must ime.

No I didn't. But the 2nd example I gave in my previous post is of a single full-range driver. The difference in measured and factory specs in that case are even more prominent than with the first example at the beginning of the thread.

Yes, they have two separate leads and are not connected.

How did you place weight on the driver if it has a tweeter in the middle?

Stuck two pairs of magnets on the diaphragm, ftont and back, symmetrically. That's an alternative to the tacky tape and weight method.

Just to add a bit.

No, DATS is not pointless. It's excellent for checking consistency between units for a start. More generally, T/S parameters were created under small-signal assumptions, and that is precisely what it provides. However, a number of manufacturers measure under higher voltage drive levels, and T/S data, as has been noted, varies with this -how much depending on the driver type / design. You can argue the toss about which is more representative -the point is there is no industry standard, and we're dealing with electro-mechanical devices that do not have stable charateristics. It also varies with break-in (run at Xmech for an hour at least 20% below Fs, preferably with varying sinewaves to avoid any potential for creating some mechanical memory) and even local atmospherics at the time of measurement. All of these can and do significantly affect results.

Finally, as GM notes, you have driver production QC tolerances. What percentage deviation from a target value is used varies with different manufacturers, nor do they all use the same values. A common one is 10% deviation from a target Fs using the same measurement methodology and conditions they used themselves. However on top of that, don't run away with the idea that if Fs (or any other single nominal) is within that QC tolerance, everything else will be. It might be. It might not.

A couple of thoughts:

-Vas measurements are notoriously problematic for home measurements. Getting weights properly fixed / distributed and accurately weighed for an added mass method can be tricky, and sealed box compliance testing has its issues as well in terms of needing to make the box, ensure it's properly sealed, check the atmospherics & internal / external pressures etc. All possible, but not necessarily 100% straightforward. However, you could use the known-mass method Jeff Bagby sometimes advocated, with a minor adjustment if you don't have Mmd and have to derive from Mms. Typically manufacturers can and do tightly control two areas: coil impedance, and the total mass of the moving components so you are likely to get something of reasonable consistency / reasonably representative.

-If you size a box: take multiple data sets once the drivers are broken in, and either use the mean value (rejecting any obvious abberations, unless it's clear you've got a unit that's significantly out, in which case it either should be returned as defective or handled individually), or if you wish to be conservative, whatever yields the largest box volume. In an ideal world you'd treat all drivers as individuals, but that's not always very practical if you end up with a pair that's 20% different from each other & require significantly different box sizes & tunings.

No, DATS is not pointless. It's excellent for checking consistency between units for a start. More generally, T/S parameters were created under small-signal assumptions, and that is precisely what it provides. However, a number of manufacturers measure under higher voltage drive levels, and T/S data, as has been noted, varies with this -how much depending on the driver type / design. You can argue the toss about which is more representative -the point is there is no industry standard, and we're dealing with electro-mechanical devices that do not have stable charateristics. It also varies with break-in (run at Xmech for an hour at least 20% below Fs, preferably with varying sinewaves to avoid any potential for creating some mechanical memory) and even local atmospherics at the time of measurement. All of these can and do significantly affect results.

Finally, as GM notes, you have driver production QC tolerances. What percentage deviation from a target value is used varies with different manufacturers, nor do they all use the same values. A common one is 10% deviation from a target Fs using the same measurement methodology and conditions they used themselves. However on top of that, don't run away with the idea that if Fs (or any other single nominal) is within that QC tolerance, everything else will be. It might be. It might not.

A couple of thoughts:

-Vas measurements are notoriously problematic for home measurements. Getting weights properly fixed / distributed and accurately weighed for an added mass method can be tricky, and sealed box compliance testing has its issues as well in terms of needing to make the box, ensure it's properly sealed, check the atmospherics & internal / external pressures etc. All possible, but not necessarily 100% straightforward. However, you could use the known-mass method Jeff Bagby sometimes advocated, with a minor adjustment if you don't have Mmd and have to derive from Mms. Typically manufacturers can and do tightly control two areas: coil impedance, and the total mass of the moving components so you are likely to get something of reasonable consistency / reasonably representative.

-If you size a box: take multiple data sets once the drivers are broken in, and either use the mean value (rejecting any obvious abberations, unless it's clear you've got a unit that's significantly out, in which case it either should be returned as defective or handled individually), or if you wish to be conservative, whatever yields the largest box volume. In an ideal world you'd treat all drivers as individuals, but that's not always very practical if you end up with a pair that's 20% different from each other & require significantly different box sizes & tunings.

Last edited:

With DATS i always measure at least 5 times in two sessions with at least a day in between. Like said humidity and temperature can alter the data a bit.

And then i work from the average of that 5 measurements, that will be the closesd to the real spes in my experience. I did have access to a Clio setup for a while and it's then i tested this method, that was with Clio 11 and Dats V2, and the result of that method was always very close to what Clio measured.

Factory specs are sometimes right, but far from always, so even the less accurate DATS measurements are often more precise if you use that method i use.

And then i work from the average of that 5 measurements, that will be the closesd to the real spes in my experience. I did have access to a Clio setup for a while and it's then i tested this method, that was with Clio 11 and Dats V2, and the result of that method was always very close to what Clio measured.

Factory specs are sometimes right, but far from always, so even the less accurate DATS measurements are often more precise if you use that method i use.

Let me see if I understood you correctly, so after I fit the speaker to a sealed box with a known volume, I run DATS and get the Fs and Qts for that specific box. Then I run a sim on, say WinISD, with both the factory data and the free-air DATS measured data and see which of the sims give me the Fs and Qts I measured with the closed box.

Did I understand you correctly?

yes, and as a bonus you can cross check things with an acoustic test.

but before testing, ensure your setup/calibration is good.

assuming your using a soundcard, use a poweramp.

after calibration you should be able to measure tests resistors very accurately, very flat imp across all frequenices and phase at 0deg.

From last night to today (19:15 here right now). I ran the driver close to Xmech at varying frequencies 30 to 90 at least for 6 hours. The ambient temperature made a big difference. The room I'm in is about 17 degrees C. At this temp fs was 72Hz. I warmed up the driver to about 24 deg C., and the fs dropped to 63Hz. Much closer to spec. which is 55Hz, but the Q values haven't changed much. Thank you for all the advice. It all makes sense now.

I have used a DATS v2 for years and I find it very useful. Generally, most manufacturers inflate their specs (sort of like photoshop for drivers) and make the Qts a bit lower than actual. The DATS measures the actual impedance curve which is quite accurate (calibrated with a 0.1% 1000ohm resistor). The TS parameters fall out of the impedance measurement. There is not room for inaccuracies if the equations in DATS used to calculate the TS parameters are correct. And I believe they are good as I have seen good results.

For the Vas measurements, use added mass and a good gram scale to weigh some plastic modeling putty. Add that to the cone for the Vas measurement. Use some blue tape to protect more sensitive cones. Alternatively, silly putty (silicone putty) is very gentle to most surfaces except fabric cones and can be used directly.

My experience is that Dayton branded drivers tend to be very close to factory specs. They don’t inflate (or make Qts lower than reality).

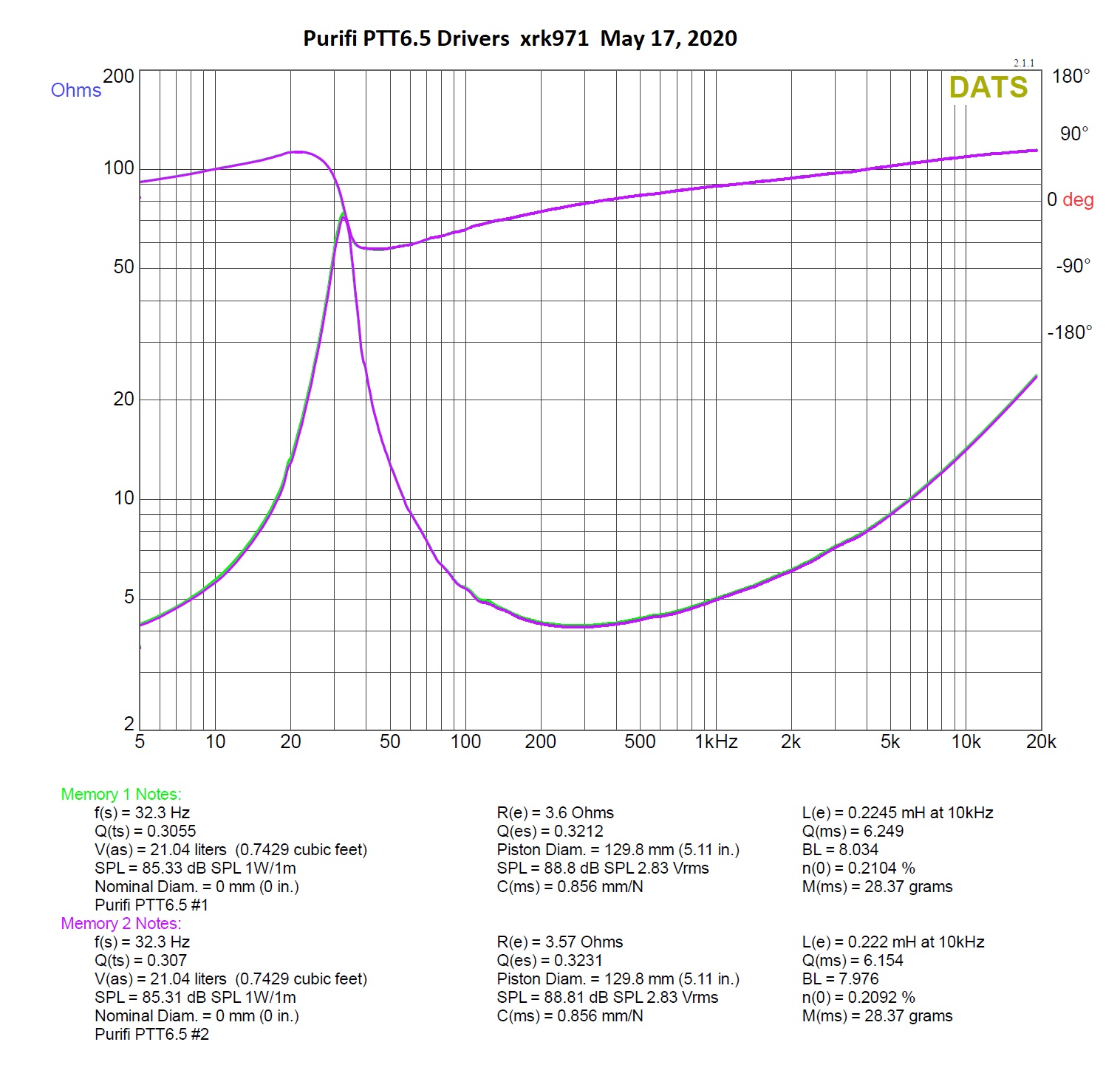

The Purifi PTT6.5 drivers I measured with my DATS matched the factory numbers almost exactly. And the two drivers measures identically. The two impedance curves landed on top of each other. Talk about consistent manufacturing.

Here is my measurement of PTT6.5 (there are 2 curves there):

Have you tried measuring some known items as an LCR meter. Measure a known capacitor, inductor, resistor. See how good those are. Caps and inductors have to be within range though. Say 4.7uF and 1mH to 5mH are good values. Measure a 10ohm 1% resistor.

For the Vas measurements, use added mass and a good gram scale to weigh some plastic modeling putty. Add that to the cone for the Vas measurement. Use some blue tape to protect more sensitive cones. Alternatively, silly putty (silicone putty) is very gentle to most surfaces except fabric cones and can be used directly.

My experience is that Dayton branded drivers tend to be very close to factory specs. They don’t inflate (or make Qts lower than reality).

The Purifi PTT6.5 drivers I measured with my DATS matched the factory numbers almost exactly. And the two drivers measures identically. The two impedance curves landed on top of each other. Talk about consistent manufacturing.

Here is my measurement of PTT6.5 (there are 2 curves there):

Have you tried measuring some known items as an LCR meter. Measure a known capacitor, inductor, resistor. See how good those are. Caps and inductors have to be within range though. Say 4.7uF and 1mH to 5mH are good values. Measure a 10ohm 1% resistor.

Last edited:

I've never had a measurement that agreed with factory specs. The measurements from different drivers from MCM, TB and SEAS don't come anywhere near the specs. So like you suggested, I'll try measuring known LCR values and see if they're measured accurately with the DATS.

More generally, T/S parameters were created under small-signal assumptions, and that is precisely what it provides. However, a number of manufacturers measure under higher voltage drive levels, and T/S data, as has been noted, varies with this -how much depending on the driver type / design. You can argue the toss about which is more representative -the point is there is no industry standard, and we're dealing with electro-mechanical devices that do not have stable charateristics.

I don't think that there is any argument. TS are parameters of a linear system and have no meaning to a nonlinear regime. Hence they only have meaning for small signals and a signal that is too large will make for erroneous numbers.

Having dealt with manufacturers for decades I can say that some are reliable and others not, so to assume that the manufacturers numbers are correct is probably not a good idea. I have seen drivers where the real specs vs, the manufacturers are like night and day. I never trusted any manufacturers numbers.

That said, it is easy for a DIY to make a mistake and this is another big issue. Doing this takes practice and signal level is one of the most critical parameters. The signal should be as low as you can get the system to work. At extremely low signal levels the speaker will pick up enough room noise to make the measurement unreliable, but just above this point, where the measurements are stable is the best that you can do.

OK. Some feel that DATS is accurate enough. Some not. Some feel that manufacturer's data could be relied upon if the manufacturer is reputable. And yet some feel that most manufacturer data is not accurate. Measuring still seems the best way to go in this case. And since the DATS makes estimations which may lead to inaccurate results (as in the OP SEAS case,) is there a more reliable speaker analyzer system within reach of us DIY'ers? Any recommendations? (I will follow the previous advices given such as testing DATS accuracy etc.)

I don't think that there is any argument. TS are parameters of a linear system and have no meaning to a nonlinear regime. Hence they only have meaning for small signals and a signal that is too large will make for erroneous numbers.

Don't get me wrong, I agree with you. From my POV there is no argument: T/S parameters were created assuming a small-signal linear-system basis, and that's the end of it as far as I'm concerned. However, I know a number of manufacturers like to suggest (no doubt for marketing purposes as they can drive the published spec. in a direction that will seem more appealing) that higher signal levels are more representative of actual operating conditions, despite the fact that we've shifted toward, or into, a non-linear regime.

Having dealt with manufacturers for decades I can say that some are reliable and others not, so to assume that the manufacturers numbers are correct is probably not a good idea. I have seen drivers where the real specs vs, the manufacturers are like night and day. I never trusted any manufacturers numbers.

I don't have anything like your experience, but on the basis of about 15 years working / dealing with a few, I agree about not making too many assumptions, and that some massive (ridiculous) variations exist.

...may lead to inaccurate results

The results are not inaccurate, just a different collapse point, and i, at least in my work, have not found the measures as useful as starting with factory numbers.

Smith+Larson WooferTester2 is the best cheap kit i have found. I still only use it for matching and dealing with drivers that have no data.

dave

Last edited:

And since the DATS makes estimations which may lead to inaccurate results )

with regard to this aspect, just overlay the free air imp with the "estimated" imp, if they are a good match then the t/s results are ok.

in the case of a good match, the use of the word "estimate" is misleading.

with regard to this aspect, just overlay the free air imp with the "estimated" imp, if they are a good match then the t/s results are ok.

I know what you are trying to say, but said this way it's wrong. No single impedance curve tells the whole story, it takes at least two to nail down all the parameters. What happens is that there are an infinite number of sets of parameters that will have an identical impedance curve. With a perturbation of either the mass or compliance, then if BOTH impedance curves match, then yes, you have the right set of parameters.

measuring driver parameters is indeed a frustrating work, even such simple things as measure driver re and le gives different results depending on which measurement system you are using

In respect of DATS accuracy with small-signal results (with proper setup/calibration and assuming its functioning properly):

Here is an older post from forum member Bikinpunk (ErinH):

Aura Sound NS6-255-8A Testing -

Techtalk Speaker Building, Audio, Video Discussion Forum

For those not "in-in-the-know", Klippel is quite likely the best in small AND large signal analysis (..though many other software + hardware combo's likely are as good as well).

Note that the results won't be the same, but they should be close overall - particularly for in-box design.

If it's between a manufacturer's spot/line testing results and DATS on a specific driver for small signal parameters: DATS.

BTW, DATS does a lot of sampling - when you test it once and then test it again under the same conditions (as recommended), the results tend to be almost identical.

Here is an older post from forum member Bikinpunk (ErinH):

Aura Sound NS6-255-8A Testing -

Techtalk Speaker Building, Audio, Video Discussion Forum

For those not "in-in-the-know", Klippel is quite likely the best in small AND large signal analysis (..though many other software + hardware combo's likely are as good as well).

Note that the results won't be the same, but they should be close overall - particularly for in-box design.

If it's between a manufacturer's spot/line testing results and DATS on a specific driver for small signal parameters: DATS.

BTW, DATS does a lot of sampling - when you test it once and then test it again under the same conditions (as recommended), the results tend to be almost identical.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Measuring speakers T/S values - DATS v.3.0 vs factory specs