Hello,

Assuming that some reviewers are dependable I have noticed lately extremely positive reviews of speakers with good but off the shelf drivers and great enclosures (i.e. high tech and high cost).

This considerations have triggered my interest in speakers cabinet design and construction

Stereophile magazine usually performs test to measure vibrations on the speakers cabinet panels by means of accelerometer.

I think that this measurement can be extremely telling.

To cut the long story short I have noticed measurements taken on the side panels and even the back panels, but never ,and I stress never, on which I think it is by a mile the most important panel, the front baffle.

Is this measurement impossible to carry out ?

I am convinced that a very still and "dead", even during strong passages, front panel is a must for an excellent music reproduction.

Then decent drivers and xovers can do the rest of the job.

Why they do not test it ?

Thanks a lot and kind regards, gino

Assuming that some reviewers are dependable I have noticed lately extremely positive reviews of speakers with good but off the shelf drivers and great enclosures (i.e. high tech and high cost).

This considerations have triggered my interest in speakers cabinet design and construction

Stereophile magazine usually performs test to measure vibrations on the speakers cabinet panels by means of accelerometer.

I think that this measurement can be extremely telling.

To cut the long story short I have noticed measurements taken on the side panels and even the back panels, but never ,and I stress never, on which I think it is by a mile the most important panel, the front baffle.

Is this measurement impossible to carry out ?

I am convinced that a very still and "dead", even during strong passages, front panel is a must for an excellent music reproduction.

Then decent drivers and xovers can do the rest of the job.

Why they do not test it ?

Thanks a lot and kind regards, gino

Last edited:

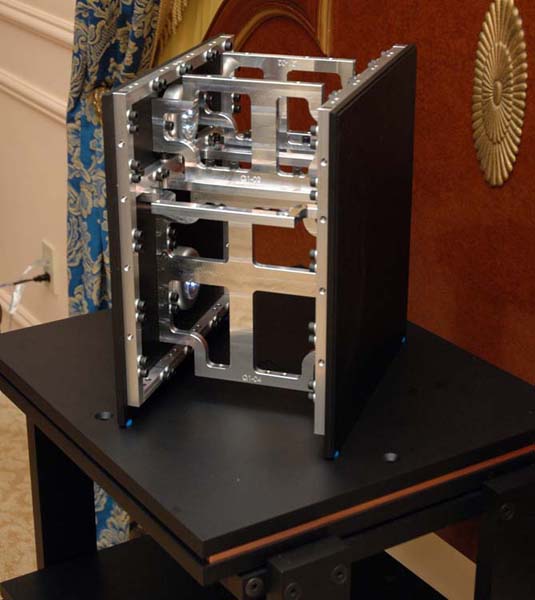

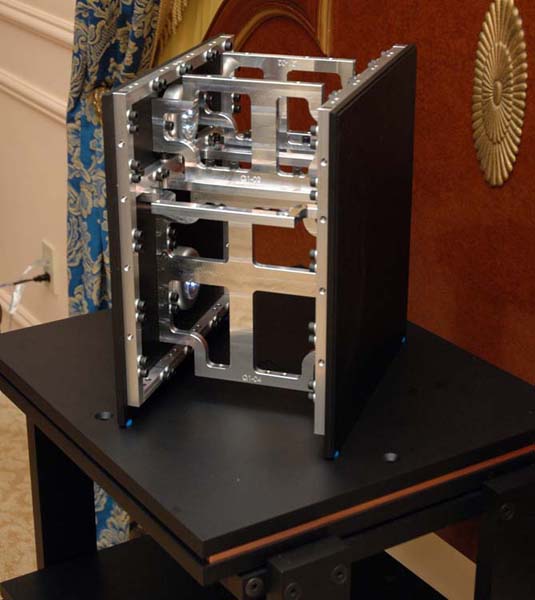

Just some examples of these high tech cabinet with great care taken for the front baffle design and construction

Magico Q1

Audiomachina front baffle (my main interest)

Rockport speakers

needless to say they have all a spectacular rendition of soundstage, the real magic in loudspeakers, at least for me.

Regards,

gino

Magico Q1

Audiomachina front baffle (my main interest)

Rockport speakers

needless to say they have all a spectacular rendition of soundstage, the real magic in loudspeakers, at least for me.

Regards,

gino

Then you are convinced correctly. 🙂I am convinced that a very still and "dead", even during strong passages, front panel is a must for an excellent music reproduction.

Then you are convinced correctly. 🙂

Hi, and thanks a lot for the very valuable reply

Then i wonder if the test with accelerometers cannot be performed also on the front baffle, given its fundamental contribution to sound.

Other designers have addressed this issue, like Epos, even if the material used is a little poor (plastic)

I would use the same design but higher grade material (like aluminum)

just make this baffle in aluminum and the sound will be even better than what already is

Thanks again and kind regards,

gino

...even if the material used is a little poor (plastic)

Why is plastic poor?

There is a huge range of materials that are called plastic. If well engineered a plastic baffle has as much or more potential as an aluminum baffle.

dave

Gino, can you please point me to a online Stereophile review containing vibration measurement? Want to see their test set-up.

Why is plastic poor?

There is a huge range of materials that are called plastic.

If well engineered a plastic baffle has as much or more potential as an aluminum baffle.

dave

Hi and thanks for the helpful reply

I understand that high tech plastics do exist. Still aluminum is used even for motorbikes frame, so my maybe wrong understanding is that a superior material for stiffness

The Epos were reasonably cheap products.

The other cost no object products i mentioned they use almost always aluminum die castings or plates.

But i am sure that the baffle design is a strong point also in the Epos

I do not think that lateral and even more rear reflections are equally detrimental to sound.

The front baffle vibrations i am sure they are, and quite a lot.

Unfortunately no measurements are available on the front panel.

And again i find this very weird.

Kind regards,

gino

Gino, can you please point me to a online Stereophile review containing vibration measurement? Want to see their test set-up.

Hi you can find some examples here for instance

The Sound of Surprise (the loudspeaker/stand interface) | Stereophile.com

but anytime they review a speaker this test is part of the protocol.

Other more sophisticated tests are based on laser measurements, i guess

An externally hosted image should be here but it was not working when we last tested it.

out of reach for a diyer but not for a big company

Once you get a "still and dead" front baffle you have a very good support for the drivers.

And even cheap but reasonably good drivers can shine.

I think i will try with fixing some metal plates inside the front baffle between the drivers to make the panel stiffer.

An externally hosted image should be here but it was not working when we last tested it.

Regards, gino

Last edited:

The skinnier the baffle the better it'll be, with wide baffles the drivers have a much better chance of flexing it in and out.

Remember that just because a material has a high stiffness does not mean it does not also have a resonant problem given a poor design and no damping. Many modern composite parts are now made of carbon fiber and many different matrix resins that are much stiffer than aluminum can achieve for the same thickness. Don't make the mistake of thinking that stiffness of the material is the only important quality.

On the order of 40 years ago, Linkwitz used a phono cart to measure cabinet vibrations....

Hi and thanks for the very interesting info

My main doubt is why no measurements on the front baffle while i have seen measurements on the side, on the top and even on the back panels.

I usually listen facing the front of the speakers

But I am a weird kind of guy

Jokes aside, is there any technical constraint that does not allow for measurements on the front baffle ?

Its vibrations are the most detrimental for sound

And actually best speakers have great front baffles

Thanks and regards

gino

Last edited:

The skinnier the baffle the better it'll be, with wide baffles the drivers have a much better chance of flexing it in and out.

Hi thanks and i agree completely

And this could be also a reason why the mini monitors usually image very well

Because they have narrow and short front baffles, and maybe also thick

I have notice that cheap minimonitors image better than cheap towers, where the baffles are long and usually also thin and they tend to flex as you say.

Moreover towers have also the woofer on the baffle that transmits vibrations to the mid-high drivers.

This is a good point for a satellite plus woofer arrangement.

Of course the best sounding towers have exceptionally well constructed front baffle, like some Rockport speakers for instance, where the front baffle is a thick sheet of metal.

Thanks and regards, gino

Last edited:

Remember that just because a material has a high stiffness does not mean it does not also have a resonant problem given a poor design and no damping.

Many modern composite parts are now made of carbon fiber and many different matrix resins that are much stiffer than aluminum can achieve for the same thickness.

Don't make the mistake of thinking that stiffness of the material is the only important quality

Hi and thanks for the explanations.

I am sure that there are very different ways to achieve this goal.

I know nothing about materials in general.

And i think that there is also a cost issue. I guess a carbon fiber panel, maybe the best solution, is a very very expensive option.

Completely out of reach for a diy design.

Still my question is why no measurements on the front baffle.

By the way i have noticed that some big companies have addressed the issue proposing plastic baffles but with stiffening elements.

Another very easy way to experiment is to screw metal bars on the center of the front panel, to counteract the flexing attitude of the front baffle.

I believe that also decoupling mechanically in some way the tweeter could be useful.

This could be the reason for speakers like this one here below ?

Thanks and regards, gino

Panel vibration measurements as in Stereophile place the accelerometer in the middle of the panel being measured as this will result in a worst case scenario with the panel flexing at this point more than others. this is easy to do with all the panels except the front baffle. There just isn't a good place to mount the accelerometer on the front panel because the drivers are in the way. Placing it to one side near a boundry means the panel isn't going to flex as much at that point so it's not going to give the measurement you desire. True, laser measurement would be better and scanning the whole surface would be an option but time consuming. I think reviewers just take some basic measurements and are happy presenting those instead.

DavidL,

Is probably more than correct about what he just said. At the same time you have to remember that some of the better cabinets will have internal bracing and just checking the center of the panel may also give a false impression of what the rest of the surface is doing. On the front panel you would also need to think about whether the driver used a stamped steel frame or a cast aluminum or other cast frame as the stiffness of the different frames is not the same at all. Usually the front panel is made thicker if the designer is thinking about panel vibrations as the thickness is a major factor in the stiffness of a flat panel. Look no further than some of the extreme enclosures that I think KEF did in the past with the entire inside of the enclosure being created as a honeycomb construction attaching all surfaces together.

Is probably more than correct about what he just said. At the same time you have to remember that some of the better cabinets will have internal bracing and just checking the center of the panel may also give a false impression of what the rest of the surface is doing. On the front panel you would also need to think about whether the driver used a stamped steel frame or a cast aluminum or other cast frame as the stiffness of the different frames is not the same at all. Usually the front panel is made thicker if the designer is thinking about panel vibrations as the thickness is a major factor in the stiffness of a flat panel. Look no further than some of the extreme enclosures that I think KEF did in the past with the entire inside of the enclosure being created as a honeycomb construction attaching all surfaces together.

Don't make the mistake of thinking that stiffness of the material is the only important quality.

Indeed! Many stiff materials ring like a bell. What you really want is high vibrational energy loss. That happens through a combination of mass, stiffness, and damping- it actually does require a bit (more than a bit...) of engineering and cleverness to achieve top results here.

Cal,

Yes, but at the same time there is much more to that than just making a flat panel with a damping layer in the center. When you go to attach those panels together you start to see the failure of that method by a simple construction method. Inner and other panels filled with sand works but sure gets heavy fast. A damping layer between two membranes take a bit of planning.

Yes, but at the same time there is much more to that than just making a flat panel with a damping layer in the center. When you go to attach those panels together you start to see the failure of that method by a simple construction method. Inner and other panels filled with sand works but sure gets heavy fast. A damping layer between two membranes take a bit of planning.

Constrained layer damping?

Hi,

There is CLD and RLD (restrained later damping).

Given a surface, say a rectangular plane, and you can

only damp 50% of the area, CLD works best placed

around the edges, and RLD in the middle of the panel.

Typical box construction prevents CLD being effective,

by preventing the edge movement it needs to damp.

Consequently RLD is the typical way it was done.

rgds, sreten.

CLD would be and is great for open baffles.

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- Measurements of box vibrations on Stereophile magazine