Have done a bit of searching on this subject, i know a lot has already been said, but i do not see a lot of info on a possible solution i am considerind to eliminate the problem.

I have just completed my cabinet construction and next stage is filling screw holes and painting. cabinets are glued pva and screwed.

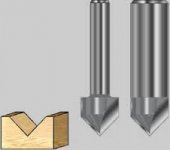

I'm wondering how successfull a trench or a "V" machined over the mdf overlaps would be, and then filled with automotive bondo.

Would this eliminate the usual lines that appear on the painted joins?

or am i creating a bigger problem?

I have just completed my cabinet construction and next stage is filling screw holes and painting. cabinets are glued pva and screwed.

I'm wondering how successfull a trench or a "V" machined over the mdf overlaps would be, and then filled with automotive bondo.

Would this eliminate the usual lines that appear on the painted joins?

or am i creating a bigger problem?

Attachments

Generally I try to have the front baffle be the full dimension piece to avoid this problem.

Lay the speaker down on it's back and "fill" the cracks with glue.

Do this multiple times if need be.

Then sand smooth.

After that, use drywall spackle to seal the end gran and compensate for the transition.

Lay the speaker down on it's back and "fill" the cracks with glue.

Do this multiple times if need be.

Then sand smooth.

After that, use drywall spackle to seal the end gran and compensate for the transition.

I have previously on a smaller job used 2 part epoxy resin on the "end grain" that i have a supply of.

It worked ok. It did fill the "end grain" well. What do you think of using epoxy to fill the cracks, laying face up as you describe. Then skim off with bondo.

Im aiming for a dead flat paint surface.

Alternatively, what do you think of the trench idea? I have seen a postind somewhere where they used what looked like a 20 - 25 mm wide trench.

It worked ok. It did fill the "end grain" well. What do you think of using epoxy to fill the cracks, laying face up as you describe. Then skim off with bondo.

Im aiming for a dead flat paint surface.

Alternatively, what do you think of the trench idea? I have seen a postind somewhere where they used what looked like a 20 - 25 mm wide trench.

It might be quite successful if you left it that way, and treated the relief as a deliberate "detail". Otherwise, veneer . . .I'm wondering how successfull a trench or a "V" machined over the mdf overlaps would be,

It might be quite successful if you left it that way, and treated the relief as a deliberate "detail". Otherwise, veneer . . .

Veneering is not an option. Definitely going to paint.

Can you elaborate on the "deliberate detail" option, like a particular router bit?

Epoxy could get messy and hard to remove.

Just be sure to prime before painting.

Bondo works well, if you are good with it then use it.

I would maybe just get a V groove bit for your router and use an edge guide.

It should make a nice 6mm groove that shouldn't be hard to fill.

I have never heard of doing this so I would be reluctant to try it myself.

Just be sure to prime before painting.

Bondo works well, if you are good with it then use it.

I would maybe just get a V groove bit for your router and use an edge guide.

It should make a nice 6mm groove that shouldn't be hard to fill.

I have never heard of doing this so I would be reluctant to try it myself.

I'm wondering whether routing along the joints would seriously compromise their strength, probably not something I would consider doing on a pair of cabinets I'd just constructed..

Perhaps a textured or faux finish would hide/disguise the joints?

Perhaps a textured or faux finish would hide/disguise the joints?

The MDF is 25mm with plenty of screws so my feeling is routing the joint lines would not compromise cabinet strenght.

You could use a sandable primer to build up layers which will help cover joints and imperfections. It comes in gray spray can or regular paint can for rolling on. I like the color and the smooth satin finish enough to leave as-is without a topcoat...

You could use the V-groove as a design element -- or any router bit.

Why not just veneer the surface.

Why not just veneer the surface.

I would veneer the surface and then paint that. The mdf edges on the front baffle will probably always show. (expansion and contraction due to heat and moisture changes will be different across the thickness and the width of the mdf) The worst thing about mdf is any sawn/machined edge.

If you veneered the speakers in a smooth melamine it would provide a very flat and even surface to paint as long as the correct primers were used. But of course you can get some good looking finishes with melamine. Do the front baffle in melamine/formica and paint the rest! Or maybe get some really nice wood veneer for the front and then paint the rest.

If you veneered the speakers in a smooth melamine it would provide a very flat and even surface to paint as long as the correct primers were used. But of course you can get some good looking finishes with melamine. Do the front baffle in melamine/formica and paint the rest! Or maybe get some really nice wood veneer for the front and then paint the rest.

Don't use latex paint on MDF without sealing first with oil based, or shellac, or just use oil based paint.

http://http://www.mkt-gmbh.com/alpha-tape/alpha-tape.php?lang=en

How about this for another option. could be rebated up to the join line.

had trouble posting this link. remove the extra http:// to view.

How about this for another option. could be rebated up to the join line.

had trouble posting this link. remove the extra http:// to view.

The secret is in the paint. I seen a large desk made of MDF primered and three thick sprayed coats of two-part polyester. The desk was then sanded and polished to a perfect mirror finish. Make tight joints to begin, fill cracks with bondo, sand well, prime and paint. Absolutely no chance of photographing!

The secret is in the paint. I seen a large desk made of MDF primered and three thick sprayed coats of two-part polyester. The desk was then sanded and polished to a perfect mirror finish. Make tight joints to begin, fill cracks with bondo, sand well, prime and paint. Absolutely no chance of photographing!

you mean telegraphing - anyone successful with a high quality paint job on MDF speaker enclosures would likely to want to share the results with photographs 😉

Well, "photographing" is the term I have always heard used for that particular problem.😎 I didn't see anyone take pictures of the desk, but it was an awesome finish. Very expensive and difficult to apply though. The spray gun must be flushed with acetone between coats.

Well, "photographing" is the term I have always heard used for that particular problem.😎 I didn't see anyone take pictures of the desk, but it was an awesome finish. Very expensive and difficult to apply though. The spray gun must be flushed with acetone between coats.

"telegraph" is a trade term for flaws in substrates showing through thin veneer or paint / finish top coats, the rest was a play on words - as I said, as much as it's generally not to my personal taste, a high quality paint job on MDF is something many would consider worthy to be shared

The biggest problem is it takes a lot of time. If you don't wait until the primer is completely cured, even if you sand flat before the next coat, it's gonna sink when the previous coats "dry" and shrink. If you're in a big enough hurry you can make several coats of primer still show the joint. If time is one of the things you certainly have, you can wait a couple-few 70+ degree F days before sanding a coat of primer.

Last edited:

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- MDF Telegraphing lines under paint.