Hey all, getting ready to make another pair of CLS panels...

Planning on using a Spring Scale to set vertical tension, just need to know value....

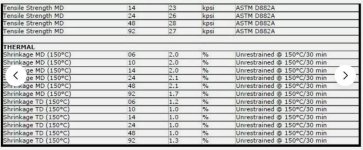

From specsheet, the Dupont Mylar C 6 micron should shrink 2% in Machine Direction, and 1.2% in Traverse Direction with 300F heat applied for 30 minutes...but we only want vertical tension, so heat shrink not an option ("barreling" of mylar over spars - yup did it)

Sooooo....Mechanically...

Elongation = F*L/A*E

F= force (what we are looking for)

L= Length

A= Cross sectional area mylar

E= Modulus of elasticity (using Mylar 710kpsi, cannot find Mylar C value)

So plugging numbers, tensioning 36 pounds should get 1% elongation.

I still think this is too high.......anyone know if this is correct, or able to check my calc?

Planning on using a Spring Scale to set vertical tension, just need to know value....

From specsheet, the Dupont Mylar C 6 micron should shrink 2% in Machine Direction, and 1.2% in Traverse Direction with 300F heat applied for 30 minutes...but we only want vertical tension, so heat shrink not an option ("barreling" of mylar over spars - yup did it)

Sooooo....Mechanically...

Elongation = F*L/A*E

F= force (what we are looking for)

L= Length

A= Cross sectional area mylar

E= Modulus of elasticity (using Mylar 710kpsi, cannot find Mylar C value)

So plugging numbers, tensioning 36 pounds should get 1% elongation.

I still think this is too high.......anyone know if this is correct, or able to check my calc?

Attachments

I don't have an answer for you but I have some questions if you don't mind my asking, and some possibly helpful comments.

Questions:

1. I think 1% elongation sounds reasonable but I'm curious: How did you decide that?

2. I prefer 6-micron Mylar but I read somewhere that Martin Logan uses 12-micron Mylar on all their panels. Is that true?

(if so; then 1% elongation would produce much higher tension in 12-micron film, compared to 6-micron film-- which points back to the question of how you settled on 1% elongation. leads me back to the 1% elongation decision came from)

3. If you want 1% elongation, why not just measure it directly, rather than calculating equivalent pulling force?

(measuring it directly by adding some reference marks on the film with a fine-tipped felt pen, and then stretching the film until the span between the marks increase by 1%)

Comments:

I use 6-micron Mylar for my speaker builds and I measure the elongation with reference marks as described above. Mine are flat panels stretched in both directions but I don't see why it wouldn't work to measure the longitudinal elongation on a curved panel.

I have practically no experience rebuilding ML panels but I once replaced the diaphragm on a ML Theater Center Channel panel.

I had no clue how much tension to apply on the diaphragm so, before I removed the old diaphragm, I measured its resonance, then made a shop aid delfection gage and measured it's deflection at center-span of the widest cell, and then tensioned the new diaphragm to the same deflection. The new diaphrgm measured the same resonance so it worked out fine.

Here's a link to a write-up with photos of that Theater panel rebuild: https://jazzman-esl-page.blogspot.com/2011/11/compensating-diplole-phase-cancellation.html

Questions:

1. I think 1% elongation sounds reasonable but I'm curious: How did you decide that?

2. I prefer 6-micron Mylar but I read somewhere that Martin Logan uses 12-micron Mylar on all their panels. Is that true?

(if so; then 1% elongation would produce much higher tension in 12-micron film, compared to 6-micron film-- which points back to the question of how you settled on 1% elongation. leads me back to the 1% elongation decision came from)

3. If you want 1% elongation, why not just measure it directly, rather than calculating equivalent pulling force?

(measuring it directly by adding some reference marks on the film with a fine-tipped felt pen, and then stretching the film until the span between the marks increase by 1%)

Comments:

I use 6-micron Mylar for my speaker builds and I measure the elongation with reference marks as described above. Mine are flat panels stretched in both directions but I don't see why it wouldn't work to measure the longitudinal elongation on a curved panel.

I have practically no experience rebuilding ML panels but I once replaced the diaphragm on a ML Theater Center Channel panel.

I had no clue how much tension to apply on the diaphragm so, before I removed the old diaphragm, I measured its resonance, then made a shop aid delfection gage and measured it's deflection at center-span of the widest cell, and then tensioned the new diaphragm to the same deflection. The new diaphrgm measured the same resonance so it worked out fine.

Here's a link to a write-up with photos of that Theater panel rebuild: https://jazzman-esl-page.blogspot.com/2011/11/compensating-diplole-phase-cancellation.html

Hello Charlie!

I remember reading the 1% measurement was the ML norm...don't remember where I saw that tho...

I also read that ML uses 12 micron mylar too...I have quite a bit of 6 micron mylar...

The 1% elongation measurement (and not tension measurement) would be nice, but I would need another person in my rig / method. But that would be best way to measure.

I remember reading the 1% measurement was the ML norm...don't remember where I saw that tho...

I also read that ML uses 12 micron mylar too...I have quite a bit of 6 micron mylar...

The 1% elongation measurement (and not tension measurement) would be nice, but I would need another person in my rig / method. But that would be best way to measure.

On the Theater panel rebuild what I didn't do but wish I had was to measure the elongation--- I only stretched the film until it's deflection at center span measured the same as that of the original diaphragm, so I'm now curious whether it's elongation would have been close to 1%.

In any case, I don't think you can go wrong with 1% elongation but I wouldn't go with any less -- better too tight than loose!

I'm accustomed to flat-panel ESL's, which are perfectly symmetric-- so what amazed me with the curved Theater panel was the degree of asymmetry between spacer-tape thicknesses on the front stator (0.025") versus on the rear stator (0.045"), and how radically asymmetric the diaphragm-to-stator spacing ended up being. The film was very close to the front stator near the spars and dipped very close to the rear stator at center-spans between spars, and yet the panel played perfectlly fine.

In any case, I don't think you can go wrong with 1% elongation but I wouldn't go with any less -- better too tight than loose!

I'm accustomed to flat-panel ESL's, which are perfectly symmetric-- so what amazed me with the curved Theater panel was the degree of asymmetry between spacer-tape thicknesses on the front stator (0.025") versus on the rear stator (0.045"), and how radically asymmetric the diaphragm-to-stator spacing ended up being. The film was very close to the front stator near the spars and dipped very close to the rear stator at center-spans between spars, and yet the panel played perfectlly fine.

Last edited: