Hey all, Considering buying some Sodium Lauryl Sulfate to spray onto a CLS Panel Diaphragm... see here...

Sodium Lauryl Sulfate-SRF-SLS-01

Looking to tape off the spars and get on the panels as best I can thru stators. Then wiping off residual on stators and leaving flat for a day or two until the coating dries...

Bad idea?

Sodium Lauryl Sulfate-SRF-SLS-01

Looking to tape off the spars and get on the panels as best I can thru stators. Then wiping off residual on stators and leaving flat for a day or two until the coating dries...

Bad idea?

Last edited:

I would just use Licron on a panel like that.

Surfactants were used a lot in earlier DIY coatings, maybe even in some newer products as well (Staticide?) and do not last, typically they are water based.

I read up a lot about surfactants in 2003 when I First started DIYin' ESL's, read everything I could possibly find about it, and other carbon black based coatings.

Back then TAC had a great article on the subject and how to use/make a Nylon 66 coating as well,and then, along came Techspray with their Licron and Licron Cyrstal an it has never failed me and those original diaphragms still work from way back then.

By reading the SDS's of such products they are basically made of salts and may respond to or even require a certain level of humidity in the air to work properly for our application.

I have always wanted to explore this some more at a later date as well, I started to a while back in 2011 or so but never made a panel yet using Surfactants and PVA glue but my first samples were very promising.

In my recent searches of what to try next I came upon the stuff that Staticde actually uses in their various mixtures of products as well, and they sell it in bulk just like Licron,

https://www.eis-inc.com/staticide-concentrate/p-acl3000q

Their are many products I have found that I would like to use that come straight from the Cosmetic industry or use in ESL design and construction and just recently found them in bulk too !! 🙂

Of those beside surfactants are, Talc for filled coatings for stators work very well, and I like their acrylic teflon filled nail polish for stator coatings could work very well, as I have used it to seal up bad HV leaking spots before during my Extreme R&D sessions.

It Worked Great !!!!! ........ but the panel itself could only take so Much !! 😉 😀

So, think about that if you plan on sealing them up permanente as usual, I personally have Only Used Licron, but I do plan on getting some Staticide 6300 next as well just to try.

ACL Staticide 6300Q ESD / Anti-Static Coating | RSHughes.com

FWIW

jer 🙂

Surfactants were used a lot in earlier DIY coatings, maybe even in some newer products as well (Staticide?) and do not last, typically they are water based.

I read up a lot about surfactants in 2003 when I First started DIYin' ESL's, read everything I could possibly find about it, and other carbon black based coatings.

Back then TAC had a great article on the subject and how to use/make a Nylon 66 coating as well,and then, along came Techspray with their Licron and Licron Cyrstal an it has never failed me and those original diaphragms still work from way back then.

By reading the SDS's of such products they are basically made of salts and may respond to or even require a certain level of humidity in the air to work properly for our application.

I have always wanted to explore this some more at a later date as well, I started to a while back in 2011 or so but never made a panel yet using Surfactants and PVA glue but my first samples were very promising.

In my recent searches of what to try next I came upon the stuff that Staticde actually uses in their various mixtures of products as well, and they sell it in bulk just like Licron,

https://www.eis-inc.com/staticide-concentrate/p-acl3000q

Their are many products I have found that I would like to use that come straight from the Cosmetic industry or use in ESL design and construction and just recently found them in bulk too !! 🙂

Of those beside surfactants are, Talc for filled coatings for stators work very well, and I like their acrylic teflon filled nail polish for stator coatings could work very well, as I have used it to seal up bad HV leaking spots before during my Extreme R&D sessions.

It Worked Great !!!!! ........ but the panel itself could only take so Much !! 😉 😀

So, think about that if you plan on sealing them up permanente as usual, I personally have Only Used Licron, but I do plan on getting some Staticide 6300 next as well just to try.

ACL Staticide 6300Q ESD / Anti-Static Coating | RSHughes.com

FWIW

jer 🙂

Thanks jer, but can the Licron (or other coating) be sprayed on the panels without opening them up? Sprayed thru the holes of the front stator having the spars taped up?

Original post was also a question of application...

Original post was also a question of application...

I'm having a hard time imagining how spraying through the perf would work, since most of these coatings are applied pretty lightly. In my experience with perforated metal stators in a high excursion environment, one of the problems was the diaphragm coating would wear off from contact with the stator, leaving conductive islands under all the holes. Those little circles were electrically isolated from the bias supply. I think you may wind up with a similar result.

Additionally, if you've taped off all around the perimeter, how is your new coating going to get to the charging zone that typically runs up the side under the spacer tape?

Additionally, if you've taped off all around the perimeter, how is your new coating going to get to the charging zone that typically runs up the side under the spacer tape?

My idea is to spray perpendicular to the stator, then spray at a 45 degree to the stator to try and prevent the "islands". Also apply is same fashion at teh stator edges where teh bias ring sits.

The space between the "islands" will still be connected via the old coating, so may not be as good as a direct application, but may offer some improvement?

The good of using the Sodium Lauryl Sulfate is if it doesn't work as well as one would hope, it could be washed off in shower...

The space between the "islands" will still be connected via the old coating, so may not be as good as a direct application, but may offer some improvement?

The good of using the Sodium Lauryl Sulfate is if it doesn't work as well as one would hope, it could be washed off in shower...

Boy, that is a tough one !!

This question has been raised before,

in General I would say yes, you could spray it through the mesh and it would most likely wet it enough to give a good coating as when it dries, it dries to a just few microns of thickness.

I had advised one Diy'er to try using a syringe to inject it on to the diaphragm with a syringe, and then he could swab it around with a Q-tip or fine paint brush of some sort to cover the damaged area where the original coating had peeled off.

This was on a large Acoustat were there is a bit more room to get around the stator wires.

I believe that he fixed them, I don't recall what thread that was.

Doing this on an ML short of ripping it apart my be tricky however I think that it may be done quite easily, and if it works it would have solved a lot of headaches back in the day for some.

ML stators are either painted or Powder coated correct?

It will be up to the integrity of this coating in order for it to work, there has to be absolutely NO Micro Cracks Or Micro Pinholes in the stator coating Whatsoever!!! ........

Else the Diaphragms Antistatic Coating Will Cause a Direct Short to the stator yielding a dead panel because there is no diaphragm charge that can be collected due to the short.

In Theory it shouldn't hurt the panels at all,

But I had all kinds of such issues with my very first panels when I was using graphic graphite powder and got it all over everything!!

Sometimes shorting out the stators and such.

I learned right quick about (but still don't fully understand about) making the insulted stator now conductive on the just the outside or just the inside with some interesting results type experiments and I wanted to get more in to but never did.

I tried the coating on both sides of the mylar vs one as well with some interesting results.

I tried everything but not in any kind of scientific order because the only problem I had at hand at the time was to resolve why I my Panel was dead when it should not have been. 😉

Gotta Love R&D the Early Days !! 😀

Most of the issues that show up with ML's are Beside their coating method, is that it has been known that the charge ring looses contact or gets corroded thus stopping the diaphragm to charge up fully.

So when you think about all of this what would happen if the diaphragms coating continued all of the way around in side that cavity it the insulated surface of the stator facing the diaphragm?

This Could Actually short out the charge on the surface of the stator created by the step-up transformer resulting in little to no movement of the diaphragm or even maybe just a partial area if it is moving.

I have experienced all of the above in my search of high performance coatings and testing at higher than "normal" voltages.

I think that if one were to attempt this I would Mask off all of the whole perimeter of the panel and mid support ribs at at least 3/4-1" from the edge of where they are sandwiched together less if you think you can get away with it, mayb 1/2" form the edge.

Okay,

So that when you spray in to the mesh the coating will be on the mesh as well but the masking will keep the coating form making a full connection to the freshly coated diaphragm surface on the inside.

And of course wipe off of surface oh the mesh with an Alcohol saturated towel to help pick up any extra residue as well before it cures.

That is about the best method that I can think up at the moment short of ripping them up for a new Diaphragm.

Cheers !!

jer 🙂

This question has been raised before,

in General I would say yes, you could spray it through the mesh and it would most likely wet it enough to give a good coating as when it dries, it dries to a just few microns of thickness.

I had advised one Diy'er to try using a syringe to inject it on to the diaphragm with a syringe, and then he could swab it around with a Q-tip or fine paint brush of some sort to cover the damaged area where the original coating had peeled off.

This was on a large Acoustat were there is a bit more room to get around the stator wires.

I believe that he fixed them, I don't recall what thread that was.

Doing this on an ML short of ripping it apart my be tricky however I think that it may be done quite easily, and if it works it would have solved a lot of headaches back in the day for some.

ML stators are either painted or Powder coated correct?

It will be up to the integrity of this coating in order for it to work, there has to be absolutely NO Micro Cracks Or Micro Pinholes in the stator coating Whatsoever!!! ........

Else the Diaphragms Antistatic Coating Will Cause a Direct Short to the stator yielding a dead panel because there is no diaphragm charge that can be collected due to the short.

In Theory it shouldn't hurt the panels at all,

But I had all kinds of such issues with my very first panels when I was using graphic graphite powder and got it all over everything!!

Sometimes shorting out the stators and such.

I learned right quick about (but still don't fully understand about) making the insulted stator now conductive on the just the outside or just the inside with some interesting results type experiments and I wanted to get more in to but never did.

I tried the coating on both sides of the mylar vs one as well with some interesting results.

I tried everything but not in any kind of scientific order because the only problem I had at hand at the time was to resolve why I my Panel was dead when it should not have been. 😉

Gotta Love R&D the Early Days !! 😀

Most of the issues that show up with ML's are Beside their coating method, is that it has been known that the charge ring looses contact or gets corroded thus stopping the diaphragm to charge up fully.

So when you think about all of this what would happen if the diaphragms coating continued all of the way around in side that cavity it the insulated surface of the stator facing the diaphragm?

This Could Actually short out the charge on the surface of the stator created by the step-up transformer resulting in little to no movement of the diaphragm or even maybe just a partial area if it is moving.

I have experienced all of the above in my search of high performance coatings and testing at higher than "normal" voltages.

I think that if one were to attempt this I would Mask off all of the whole perimeter of the panel and mid support ribs at at least 3/4-1" from the edge of where they are sandwiched together less if you think you can get away with it, mayb 1/2" form the edge.

Okay,

So that when you spray in to the mesh the coating will be on the mesh as well but the masking will keep the coating form making a full connection to the freshly coated diaphragm surface on the inside.

And of course wipe off of surface oh the mesh with an Alcohol saturated towel to help pick up any extra residue as well before it cures.

That is about the best method that I can think up at the moment short of ripping them up for a new Diaphragm.

Cheers !!

jer 🙂

Last edited:

May I ask, why not split the panels John65B ? Older ML panels should be much easier to split. Unlike my Odyssey which was double taped all round that really required lots of patience & time to split the stators but I still manage to do so & recoated the Mylar.

Another issue, let's presume you have success by spraying through the stators, what makes you think that the bias strip is still in good condition ?????

Another issue, let's presume you have success by spraying through the stators, what makes you think that the bias strip is still in good condition ?????

I have split three sets of CLS panels and only once not damaged the mylar.

I have a set of panels that look like new - and still secured all the way around, just that the output somewhat low.

As far as the bias ring, if I can get some of the spray liquid into the panel edge creases, chances are I could get some of the solution onto the bias ring...

I understand not ideal, but it could work...

I have a set of panels that look like new - and still secured all the way around, just that the output somewhat low.

As far as the bias ring, if I can get some of the spray liquid into the panel edge creases, chances are I could get some of the solution onto the bias ring...

I understand not ideal, but it could work...

Yep that was my thought next and forgot to type,

use a syringe to inject it into the middle of the bond from the outside edge of the of the panel, hopefully this will saturate the spongy foam tape to make contact with the thin wire that they use.

This will not effect the stators operation at all as they are insulated, and as long as their coating is not punctured your good to go.

Even though a charge ring was mean't to cure this issue, It seems to fail a lot, it only takes one good connection to a uniformly coated diaphragm to enable it to charge fully.

FWIW

jer 🙂

use a syringe to inject it into the middle of the bond from the outside edge of the of the panel, hopefully this will saturate the spongy foam tape to make contact with the thin wire that they use.

This will not effect the stators operation at all as they are insulated, and as long as their coating is not punctured your good to go.

Even though a charge ring was mean't to cure this issue, It seems to fail a lot, it only takes one good connection to a uniformly coated diaphragm to enable it to charge fully.

FWIW

jer 🙂

Last edited:

John65b, go for it, let us know good are bad if you can i know you working on minny things. I would start were the bias wire come in,i would have the panels playing as i spray... good luck have fun

thanks

thanks

Last edited:

spraying trough the stators is a no go im afraid. first of you will also make the stators conductive. witch makes it possible to jump from foil to coating on the laquer of the stators then trough the paint to the steel. and it will also result in an uneven coating on the foil. doubt if it even becomes one connecting layer 🙁

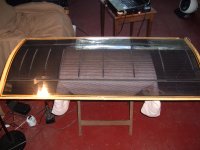

I have work with these old ML panels ....ML never solder the red bias feed wires on the copper strip...i well never get this.... if he can get lucky an get some coating at the strip the panels may come back....but hole panels well see, john65b is a good man....hes had his hands on a lot of ESLs...i got lucky these ML CLS panles pop open.....see the pic the red wire just feel out but there working today an there sounding as good as any speaker i have owned....runing them with Acoustat MK121 interfaces, sounds better than an ML interfaces.....

Jim Strickland was a esl genius....well that is this one mans O-pine

Jim Strickland was a esl genius....well that is this one mans O-pine

Attachments

- Home

- Loudspeakers

- Planars & Exotics

- Martin Logan CLS - Spray on Coating?