Here is my Maggie .7-ish clone I just completed. Started this because I was board with building box speakers, but was not expecting much. These have now replaced the speakers in my main system. I was very surprised at how much I liked the sound. For those who care about bass, using test tones I have good response down to 45hz, then drops off rapidly below that.

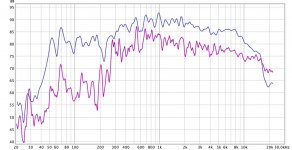

Pictures attached of the final speakers (minus trim, still deciding what I want), response (in room, center of panel height, 60" away, 1/24 smoothing), and random build pictures. I also included a picture of my first failure. I originally tried to make just the panel first using the perforated metal base and steel spacers, but it wasn't strong enough after stretching and attaching the mylar and spontaneously disassembled itself. The final product has the perforated metal and spacers (now wood for better adhesion to the mylar) directly screwed to the frame. Probably better this way anyway.

Here are the details for those who like details (sorry for mixed units)

Dimensions overal 15"x54"

Mylar unsupported dimension 11"x46", 0.005" thickness

Frame - 18mm Baltic Birch (less dust then MDF when cutting and stiffer)

Perforated metal - 0.036" thick, 0.075" hole size, 51% open area

Spacers - 3mm thickness craft plywood

Magnets - 0.06" thickness, tweeter width 0.125", woofer width 0.25"

- Seven rows for tweeter, 26 rows for woofer

- Approximately 0.08" spacing for all

Aluminum - 3M aluminum tapes, tweeter 0.0012" thickness approximately 2mm wide

- Woofer 0.0028" thickness approximately 2.8mm wide

- Cut using a roll cutter and adding a second blade with washer spacers to get correct width (unroll, cut about 18" length and repeat for about 1 hour for each woofer)

- Tweeter about 3.8 ohm, woofer about 4.2 ohm

X-Over - Single 2.5mH inductor on the woofer gives close to a 1st order acoustic roll off around 1khz. Single 25uF cap on tweeter gives a 1st order initial acoustic roll off which steepens after. Final response is pretty flat and sounds great to my ears. Ended up padding the tweeter with 1.2ohm resistor in room as it was a little bright to me.

That's about it. Hope you enjoyed my project.

Pictures attached of the final speakers (minus trim, still deciding what I want), response (in room, center of panel height, 60" away, 1/24 smoothing), and random build pictures. I also included a picture of my first failure. I originally tried to make just the panel first using the perforated metal base and steel spacers, but it wasn't strong enough after stretching and attaching the mylar and spontaneously disassembled itself. The final product has the perforated metal and spacers (now wood for better adhesion to the mylar) directly screwed to the frame. Probably better this way anyway.

Here are the details for those who like details (sorry for mixed units)

Dimensions overal 15"x54"

Mylar unsupported dimension 11"x46", 0.005" thickness

Frame - 18mm Baltic Birch (less dust then MDF when cutting and stiffer)

Perforated metal - 0.036" thick, 0.075" hole size, 51% open area

Spacers - 3mm thickness craft plywood

Magnets - 0.06" thickness, tweeter width 0.125", woofer width 0.25"

- Seven rows for tweeter, 26 rows for woofer

- Approximately 0.08" spacing for all

Aluminum - 3M aluminum tapes, tweeter 0.0012" thickness approximately 2mm wide

- Woofer 0.0028" thickness approximately 2.8mm wide

- Cut using a roll cutter and adding a second blade with washer spacers to get correct width (unroll, cut about 18" length and repeat for about 1 hour for each woofer)

- Tweeter about 3.8 ohm, woofer about 4.2 ohm

X-Over - Single 2.5mH inductor on the woofer gives close to a 1st order acoustic roll off around 1khz. Single 25uF cap on tweeter gives a 1st order initial acoustic roll off which steepens after. Final response is pretty flat and sounds great to my ears. Ended up padding the tweeter with 1.2ohm resistor in room as it was a little bright to me.

That's about it. Hope you enjoyed my project.

Attachments

-

Final Panels.jpg825.7 KB · Views: 268

Final Panels.jpg825.7 KB · Views: 268 -

Naked Panel.jpg568.5 KB · Views: 278

Naked Panel.jpg568.5 KB · Views: 278 -

Response.jpg97.8 KB · Views: 290

Response.jpg97.8 KB · Views: 290 -

Raw Drivers.jpg119.4 KB · Views: 280

Raw Drivers.jpg119.4 KB · Views: 280 -

X-Over Response.jpg120.1 KB · Views: 277

X-Over Response.jpg120.1 KB · Views: 277 -

Frame Build.jpg460.5 KB · Views: 188

Frame Build.jpg460.5 KB · Views: 188 -

Mylar Stretching.jpg820.7 KB · Views: 202

Mylar Stretching.jpg820.7 KB · Views: 202 -

Aluminum Slitting.jpg940.7 KB · Views: 189

Aluminum Slitting.jpg940.7 KB · Views: 189 -

Tweeter Foil.jpg596.3 KB · Views: 204

Tweeter Foil.jpg596.3 KB · Views: 204 -

Failure.jpg520.1 KB · Views: 202

Failure.jpg520.1 KB · Views: 202

Thanks Webbi

I got them from a Canadian company.

Magnet Supplier for Commercial and Personal Applications | Order Bulk Magnets to Keep Costs Low

They have high energy strip magnets and will sell by 100 ft quantities.

I got them from a Canadian company.

Magnet Supplier for Commercial and Personal Applications | Order Bulk Magnets to Keep Costs Low

They have high energy strip magnets and will sell by 100 ft quantities.