Two quick thoughts:

1.

2. A heavy coating (or soaking) of shellac would be expected to not only stiffen the paper, but to also help seal it from atmospheric moisture. In woodworking, shellac is available with varying amounts of intrinsic color, so color alone is not specifically indicative of the quantity. But to my point: It is well known that wooden acoustic instruments' sound is influenced by humidity. An easier demonstration is the effect of moisture on paper stiffness. Both wood and paper, of course, are different configurations of cellulose fiber and the chemical nature of cellulose attracts and maintains a molecular coating of water molecules. So when thinking about the best paper for cones, I tend to favor material made with coarser natural fibers (a trait of the various plant cells that originally deposited the structural cellulose) rather than very fine fibers (eg. cotton). But of course, that simple variable alone wouldn't explain all of the possible results from using different cone papers.

1.

Any structural decay at the cone-to-former joint would theoretically affect sound via energy transfer into the cone, but I would certainly not welcome that weakening. I would hope for the break-in to only improve compliance of the cone suspension. In my experience with many different drivers, break-in continues well beyond 30-40 hours. Also, even well used speakers loose their detail if left unused for a sufficient period. But of course, they regain their previous sound rapidly compared to the original break-in period. I have always suspected that behavior to be a property of the cones' suspensions.The break-in is the result of the paper fibers becoming more flexible at the cone-to-former interface, and allowing flexure at certain frequencies. The heavier coating will require more force/longer time to break down.

2. A heavy coating (or soaking) of shellac would be expected to not only stiffen the paper, but to also help seal it from atmospheric moisture. In woodworking, shellac is available with varying amounts of intrinsic color, so color alone is not specifically indicative of the quantity. But to my point: It is well known that wooden acoustic instruments' sound is influenced by humidity. An easier demonstration is the effect of moisture on paper stiffness. Both wood and paper, of course, are different configurations of cellulose fiber and the chemical nature of cellulose attracts and maintains a molecular coating of water molecules. So when thinking about the best paper for cones, I tend to favor material made with coarser natural fibers (a trait of the various plant cells that originally deposited the structural cellulose) rather than very fine fibers (eg. cotton). But of course, that simple variable alone wouldn't explain all of the possible results from using different cone papers.

.Normally I don't use shellac, because not all types of paper harden and stiffen in shellac. But I use an alternative paper sealant and varnish, which contain this chemical: Ethyl 3-Ethoxypropionate

Interesting. One might expect the Ethyl 3-Ethoxypropionate, with 3 hydrogen bond acceptors, to integrate into the cellulose hydroxyls and displace some of the adsorbed water. This could improve incorporation of the resin - do you know the type of resin?

Typically, the EnABL process is finished with a dilute acrylic sealant - very water soluble.

Typically, the EnABL process is finished with a dilute acrylic sealant - very water soluble.

Sometimes I use hair spray applied with a brush. It evaporates fast and hardens the paper cone. (learned about it on the Melhuish fullrange driver forum more than 20 years ago).

Now the sound is better in the bass but worse in the mids forcing "shouting" sound.

Could cure this negative side effect of cone stiffening with additionally applying one or two sided thin aluminium foil.

The effect of the foil overrides the effect of putting lacquer / dammar / varnish or shellac.

All paper cones I treated with foil from one sided up to sandwich "foil - paper - foil" arrangement then get the same clean and fast sound.

For me concerning sound of fullrange drivers it's beside dsp application the most important tweak you can do.

Now the sound is better in the bass but worse in the mids forcing "shouting" sound.

Could cure this negative side effect of cone stiffening with additionally applying one or two sided thin aluminium foil.

The effect of the foil overrides the effect of putting lacquer / dammar / varnish or shellac.

All paper cones I treated with foil from one sided up to sandwich "foil - paper - foil" arrangement then get the same clean and fast sound.

For me concerning sound of fullrange drivers it's beside dsp application the most important tweak you can do.

This is my 8 inch field coil fullrange that I designed 6 years ago.

@ghemml & other Lowtherfiles

I figured I’d post here for some feedback since this is DX4 related.

I’ve not made much progress on a Lowther field coil project I started gathering bits for since I relocated to a new house last Fall…surprise!

My impatience got the better of me when I came across a used pair of DX4 for sale cheaply.

They were fairly local and advertised as one driver needing a voice coil realigned. I thought I’d give them a try in the mean time since I only ever used DX3 drivers before and had read the DX4 was a step up.

Well, I got my hands on them and there seems to be more issues than a mis-aligned voice coil…surprise again!!

I couldn’t get rubbing to go away in the voicecoil of the one driver no matter how much I fussed with it.

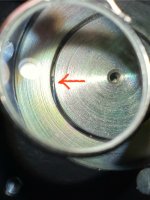

After I examined it more closely with a loop it became clear that there was debris in the magnet gap.

Upon removal of the magnet to clean the gap I discovered things were a bit worse.

It appears that the yellow cadmium style plating that is on the magnet extends into the gap…and it is delaminating there.

I have already pulled out a few large flakes of it along with a bunch of fine grey grit and dust (see pics).

I let the seller know the situation and they have offered the option of returning them for a refund or keeping them for parts to tinker with.

I’m not sure if it’s possible to clear the gap on the magnet…or if the full depth of the gap actually needs to be clear?

The only other idea I had was to try taking the magnets off of a pair of PM6A drivers I have that need surrounds and transferring them to the DX4 frames/cones which at least appear to be in decent useable condition.

Neither pair of speakers were very expensive…especially since the seller offered to give me money back if I want the DX4 for parts.

Is it possible to swap the magnets like this between the DX4 and PM6A and then re-align the coils? Both drivers appear to have the same 4 bolt pattern.

The PM6A were not originally a pair anyway. They don’t match closely like the DX4 when I measure their impedance either.

If this would work, I could at least have one good useable pair of drivers.

I am wondering whether I will have an issue with the paper shims that go between the basket and magnet assembly. It seems like they are necessary to get the voice coil to the correct depth in the magnet gap. I can’t find any detailed information or instructions regarding them.

In the end, I could just use the frames from the PM6A to mount new cones with surrounds that I bought from ghemml and build them into the field coils I want when I have my workshop set up and can continue with the electro magnet machining.

Any feedback or experience and enlightenment on the situation is appreciated.

I figured I’d post here for some feedback since this is DX4 related.

I’ve not made much progress on a Lowther field coil project I started gathering bits for since I relocated to a new house last Fall…surprise!

My impatience got the better of me when I came across a used pair of DX4 for sale cheaply.

They were fairly local and advertised as one driver needing a voice coil realigned. I thought I’d give them a try in the mean time since I only ever used DX3 drivers before and had read the DX4 was a step up.

Well, I got my hands on them and there seems to be more issues than a mis-aligned voice coil…surprise again!!

I couldn’t get rubbing to go away in the voicecoil of the one driver no matter how much I fussed with it.

After I examined it more closely with a loop it became clear that there was debris in the magnet gap.

Upon removal of the magnet to clean the gap I discovered things were a bit worse.

It appears that the yellow cadmium style plating that is on the magnet extends into the gap…and it is delaminating there.

I have already pulled out a few large flakes of it along with a bunch of fine grey grit and dust (see pics).

I let the seller know the situation and they have offered the option of returning them for a refund or keeping them for parts to tinker with.

I’m not sure if it’s possible to clear the gap on the magnet…or if the full depth of the gap actually needs to be clear?

The only other idea I had was to try taking the magnets off of a pair of PM6A drivers I have that need surrounds and transferring them to the DX4 frames/cones which at least appear to be in decent useable condition.

Neither pair of speakers were very expensive…especially since the seller offered to give me money back if I want the DX4 for parts.

Is it possible to swap the magnets like this between the DX4 and PM6A and then re-align the coils? Both drivers appear to have the same 4 bolt pattern.

The PM6A were not originally a pair anyway. They don’t match closely like the DX4 when I measure their impedance either.

If this would work, I could at least have one good useable pair of drivers.

I am wondering whether I will have an issue with the paper shims that go between the basket and magnet assembly. It seems like they are necessary to get the voice coil to the correct depth in the magnet gap. I can’t find any detailed information or instructions regarding them.

In the end, I could just use the frames from the PM6A to mount new cones with surrounds that I bought from ghemml and build them into the field coils I want when I have my workshop set up and can continue with the electro magnet machining.

Any feedback or experience and enlightenment on the situation is appreciated.

Attachments

I don't know enough to be of help but if the other unit still worked acceptably, you might try mono or up-firing omni (too late to try that on the disassembled unit?). For me, one PM2A required rotation and one PM6A got its unprotected inverted-surround cut and rubbed after white-glue repair.

For omni I finger-moulded a roll of very thin gasket foam into a deflector, after Citation 360. Got stereo sound working but didn't like the response and extra exertion. Later I got an inexpensive pair of Taiwan sonic clone (Hicastle) and omni'ed them with tea-strainers (pic in photo gallery).

For omni I finger-moulded a roll of very thin gasket foam into a deflector, after Citation 360. Got stereo sound working but didn't like the response and extra exertion. Later I got an inexpensive pair of Taiwan sonic clone (Hicastle) and omni'ed them with tea-strainers (pic in photo gallery).

Last edited:

couldn't thorough work with sand paper help cleaning the gap and finishing with a vacuum cleaner?

Thanks for the responses.

I’d like the results of my efforts to be a stereo pair of drivers.

I have read Lowther’s “Maintenance” document for dealing with rubbing voice coils.

They provide advice for removing debris from the gap with folded sticky tape and the like.

Using sandpaper would probably result in a lot more metal debris in the gap to remove.

No guidance for the situation I’m describing with plating delaminating is offered in the Lowther document.

I made myself a tool out of some stainless steel welding rod by hammering it’s end out on a vise/anvil into a blade thin enough to be able to insert down into the gap and try to remove pieces of the plating that are loose or protruding into the path of the voice coil former by scraping them off and towards the top of the gap where I can grab them with tape.

It’s slow tedious work and I’m not convinced it’s possible to really get it all out simply because of the shelf that is formed by the top plate near the top of the gap.

I have tried blowing out the gap with compressed air at 120PSI from my shop compressor. Dust came out on the first attempt.

However further examination with a loop revealed that the larger metallic particles cling to the sides of the gap and just sort of slide around when blasted with air. A vacuum just wouldn’t have the power to remove them.

I’d like the results of my efforts to be a stereo pair of drivers.

I have read Lowther’s “Maintenance” document for dealing with rubbing voice coils.

They provide advice for removing debris from the gap with folded sticky tape and the like.

Using sandpaper would probably result in a lot more metal debris in the gap to remove.

No guidance for the situation I’m describing with plating delaminating is offered in the Lowther document.

I made myself a tool out of some stainless steel welding rod by hammering it’s end out on a vise/anvil into a blade thin enough to be able to insert down into the gap and try to remove pieces of the plating that are loose or protruding into the path of the voice coil former by scraping them off and towards the top of the gap where I can grab them with tape.

It’s slow tedious work and I’m not convinced it’s possible to really get it all out simply because of the shelf that is formed by the top plate near the top of the gap.

I have tried blowing out the gap with compressed air at 120PSI from my shop compressor. Dust came out on the first attempt.

However further examination with a loop revealed that the larger metallic particles cling to the sides of the gap and just sort of slide around when blasted with air. A vacuum just wouldn’t have the power to remove them.

Attachments

Really sounds nice, even through my phone.This is my 8 inch field coil fullrange that I designed 6 years ago.

View attachment 1339831

View attachment 1339834

View attachment 1339835

Well I spent another afternoon scraping and cleaning out the magnet gap as best I could with my little stainless tool, tape and compressed air until my compressor broke again 😒

Then I tweaked the voice coil former a bit by hand because it looked a little out of round.

Figured I would try putting it back together and see what happens.

It appears to be aligned and working properly.

I used a tone generator App and a cheap eBay chip amp to play a 20 Hertz tone through it loud enough to make the cone pump back and forth almost 1/4” and I don’t hear any rubbing.

No idea how long it will stay that way.

If more stuff comes loose in the magnet and binds up the voice coil gap again I’ll have to disassemble it and do the same thing all over again I guess.

Then I tweaked the voice coil former a bit by hand because it looked a little out of round.

Figured I would try putting it back together and see what happens.

It appears to be aligned and working properly.

I used a tone generator App and a cheap eBay chip amp to play a 20 Hertz tone through it loud enough to make the cone pump back and forth almost 1/4” and I don’t hear any rubbing.

No idea how long it will stay that way.

If more stuff comes loose in the magnet and binds up the voice coil gap again I’ll have to disassemble it and do the same thing all over again I guess.

This is just for fun…

I couldn’t figure out how to post a video yesterday. What a hassle to have to convert the file!

I couldn’t figure out how to post a video yesterday. What a hassle to have to convert the file!

Hi, just saw your post.@ghemml & other Lowtherfiles

I figured I’d post here for some feedback since this is DX4 related.

I’ve not made much progress on a Lowther field coil project I started gathering bits for since I relocated to a new house last Fall…surprise!

My impatience got the better of me when I came across a used pair of DX4 for sale cheaply.

They were fairly local and advertised as one driver needing a voice coil realigned. I thought I’d give them a try in the mean time since I only ever used DX3 drivers before and had read the DX4 was a step up.

Well, I got my hands on them and there seems to be more issues than a mis-aligned voice coil…surprise again!!

I couldn’t get rubbing to go away in the voicecoil of the one driver no matter how much I fussed with it.

After I examined it more closely with a loop it became clear that there was debris in the magnet gap.

Upon removal of the magnet to clean the gap I discovered things were a bit worse.

It appears that the yellow cadmium style plating that is on the magnet extends into the gap…and it is delaminating there.

I have already pulled out a few large flakes of it along with a bunch of fine grey grit and dust (see pics).

I let the seller know the situation and they have offered the option of returning them for a refund or keeping them for parts to tinker with.

I’m not sure if it’s possible to clear the gap on the magnet…or if the full depth of the gap actually needs to be clear?

The only other idea I had was to try taking the magnets off of a pair of PM6A drivers I have that need surrounds and transferring them to the DX4 frames/cones which at least appear to be in decent useable condition.

Neither pair of speakers were very expensive…especially since the seller offered to give me money back if I want the DX4 for parts.

Is it possible to swap the magnets like this between the DX4 and PM6A and then re-align the coils? Both drivers appear to have the same 4 bolt pattern.

The PM6A were not originally a pair anyway. They don’t match closely like the DX4 when I measure their impedance either.

If this would work, I could at least have one good useable pair of drivers.

I am wondering whether I will have an issue with the paper shims that go between the basket and magnet assembly. It seems like they are necessary to get the voice coil to the correct depth in the magnet gap. I can’t find any detailed information or instructions regarding them.

In the end, I could just use the frames from the PM6A to mount new cones with surrounds that I bought from ghemml and build them into the field coils I want when I have my workshop set up and can continue with the electro magnet machining.

Any feedback or experience and enlightenment on the situation is appreciated.

This is a common issue with Lowther voice coil coated with Magnetic Primer. They will flake off and get trapped in the magnetic gap.

What I suggest is the use masking tapes rather than clear tapes that you posted in your photo. Use masking tape that is 10mm wide with a plastic wood filler spreader which I got from Daiso

Need lots of time patience

Thanks for the tip…I’ll try that in the future if I have to do the same process again.

I’m wondering if I should examine the gap of the second driver. I haven’t tested it yet with any kind if signal. I didn’t observe any rubbing issues when I tested it by hand. If it ain’t broke don’t fix it?

Any guidance concerning interchangeability of DX4 and PM6A magnets in case I need/want to do that in the future?

Also…the question of the paper shims between the magnet and frame. Are they there to shim the voice coil to a specific depth in the gap?

Perhaps they just facilitate easier centering of the voice coil by providing a release between the surfaces of the magnet and basket?

I’m wondering if I should examine the gap of the second driver. I haven’t tested it yet with any kind if signal. I didn’t observe any rubbing issues when I tested it by hand. If it ain’t broke don’t fix it?

Any guidance concerning interchangeability of DX4 and PM6A magnets in case I need/want to do that in the future?

Also…the question of the paper shims between the magnet and frame. Are they there to shim the voice coil to a specific depth in the gap?

Perhaps they just facilitate easier centering of the voice coil by providing a release between the surfaces of the magnet and basket?

Last edited:

Have you asked lowther about the problem? I would send the magnet back to be exchanged for new one. This is clearly desing flaw.Thanks for the responses.

I’d like the results of my efforts to be a stereo pair of drivers.

I have read Lowther’s “Maintenance” document for dealing with rubbing voice coils.

They provide advice for removing debris from the gap with folded sticky tape and the like.

Using sandpaper would probably result in a lot more metal debris in the gap to remove.

No guidance for the situation I’m describing with plating delaminating is offered in the Lowther document.

I made myself a tool out of some stainless steel welding rod by hammering it’s end out on a vise/anvil into a blade thin enough to be able to insert down into the gap and try to remove pieces of the plating that are loose or protruding into the path of the voice coil former by scraping them off and towards the top of the gap where I can grab them with tape.

It’s slow tedious work and I’m not convinced it’s possible to really get it all out simply because of the shelf that is formed by the top plate near the top of the gap.

I have tried blowing out the gap with compressed air at 120PSI from my shop compressor. Dust came out on the first attempt.

However further examination with a loop revealed that the larger metallic particles cling to the sides of the gap and just sort of slide around when blasted with air. A vacuum just wouldn’t have the power to remove them.

Hi Adason

I’m on my own with this one. They are an older used pair I bought off US Audio Mart. No warranty.

The seller actually inquired with Lowther. They won’t sell you a magnet. The only option they offer is to send them in for repair. The estimate was £390 each plus shipping both ways to/from Britain…NOT happening. I could almost buy a new pair for that.

I’ve got it working now and am hoping it’ll give me some time to try and enjoy them.

I’m going to test the second driver later with a 20 Hz tone to see how it performs.

If all is good then I’ll figure out a way to set them up to play some music.

I hope things go well with them. To be honest, I only paid $300 for them in the end. They are probably worth more than that just as parts.

I’m on my own with this one. They are an older used pair I bought off US Audio Mart. No warranty.

The seller actually inquired with Lowther. They won’t sell you a magnet. The only option they offer is to send them in for repair. The estimate was £390 each plus shipping both ways to/from Britain…NOT happening. I could almost buy a new pair for that.

I’ve got it working now and am hoping it’ll give me some time to try and enjoy them.

I’m going to test the second driver later with a 20 Hz tone to see how it performs.

If all is good then I’ll figure out a way to set them up to play some music.

I hope things go well with them. To be honest, I only paid $300 for them in the end. They are probably worth more than that just as parts.

Thanks for the tip…I’ll try that in the future if I have to do the same process again.

I’m wondering if I should examine the gap of the second driver. I haven’t tested it yet with any kind if signal. I didn’t observe any rubbing issues when I tested it by hand. If it ain’t broke don’t fix it?

Any guidance concerning interchangeability of DX4 and PM6A magnets in case I need/want to do that in the future?

Also…the question of the paper shims between the magnet and frame. Are they there to shim the voice coil to a specific depth in the gap?

Perhaps they just facilitate easier centering of the voice coil by providing a release between the surfaces of the magnet and basket?

PM6A and DX4 voice coil former height is roughly about the same, around 16 to 17mm tall. The only model that has short voice coil former is the ceramic series.

The shims used to keep the voice coil in the gap within 0.5mm. Voice coil should not be out by more than 2mm or 3mm, this will cause distortion when you have low freq input.

For centering of the voice coil, the older models, have 1mm gap which can be a headache to center it. Newer models Lowther start to make the gap 1.2 to 1.3mm which helps a lot in the alignments. But I recommend using a signal generator with a single sine tone using 50hz or 60hz. Increase the volume until you start to hear the flapping sound, then slowly tighten the bolts diagonally.

Thanks for sharing all that information regarding the voice coil, shims and gap. It will be very useful when I start working on the PM6A drivers.

I’m still debating on whether the PM6A are worth putting new surrounds on or if I should just use the frames to mount the cone assemblies I got from you. I’m not sure I’d be able to properly center the 16 Ohm voice coils in the stock gap.

For now, I seem to have sorted out the DX4 drivers well enough to try using them. I’m thinking of trying them in Martin King’s ML TL…although it might be smarter to just put them on a baffle for a little while before investing the time, energy and resources in the enclosure.

I’m still debating on whether the PM6A are worth putting new surrounds on or if I should just use the frames to mount the cone assemblies I got from you. I’m not sure I’d be able to properly center the 16 Ohm voice coils in the stock gap.

For now, I seem to have sorted out the DX4 drivers well enough to try using them. I’m thinking of trying them in Martin King’s ML TL…although it might be smarter to just put them on a baffle for a little while before investing the time, energy and resources in the enclosure.

- Home

- Loudspeakers

- Full Range

- Lowther DX4 rebuild