These are big tweeters that used to be sold at Jaycar way back

Designed by TSG in the USA if that means anything to members

32 ~ 35mm Voice coils [ I'll take the faceplate off and measure later] with a drilled pole and a plastic back cap.

At the moment while they are working the Fs is much higher than than the catalogue says they should be. One sits at 665Hz and the other at 580Hz and it should be much lower around 350/400.

Leading on from the other threads on tweeter modifications is the best way to play with these taking the back cap off and making it larger so it can be stuffed with something like long fibre wool?

EDIT

32mm

Designed by TSG in the USA if that means anything to members

32 ~ 35mm Voice coils [ I'll take the faceplate off and measure later] with a drilled pole and a plastic back cap.

At the moment while they are working the Fs is much higher than than the catalogue says they should be. One sits at 665Hz and the other at 580Hz and it should be much lower around 350/400.

Leading on from the other threads on tweeter modifications is the best way to play with these taking the back cap off and making it larger so it can be stuffed with something like long fibre wool?

EDIT

32mm

Last edited:

Here are the first pix

I can't find my old catalogues to double check my assumptions about the resonance frequency, but even so I'd like to get these to mate with that S/H garage sale Peerless woofer I got a while back.

Would heating in a low over damage the drivers assuming I popped the voice coils out

I can't find my old catalogues to double check my assumptions about the resonance frequency, but even so I'd like to get these to mate with that S/H garage sale Peerless woofer I got a while back.

Would heating in a low over damage the drivers assuming I popped the voice coils out

Attachments

Standard answer to that is o drill a hole thru the pole piece and dramatically inmcrease the back chamber.

I had some VIFA D27 that had been done to (amoungst other mods) that was definitly improved. Scott (@Scottmoose) has them now, they may surface in something.

dave

I had some VIFA D27 that had been done to (amoungst other mods) that was definitly improved. Scott (@Scottmoose) has them now, they may surface in something.

dave

I read this as a 32mm VC

Attachments

So my question is how best to remove the back cap and would a felt doughnut on the top of the pole piece improve anything? Assuming I can get pure wool felt of the correct thickness; what-ever that is

Well I am having the devil of a time here. The glue on the black plastic is resistant to the amount of heat I was giving them with the hair drier. Not like the Vifa D27 which popped of with just a little heat and some leverage with a steel ruler.

Some sort of plastic polymer dome and I might need to re-do the ferrofluid, it has dried out a tad.

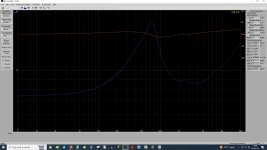

I got my little mosquito clamps and pulled out the factory damping via the pole and it was simply some semi rigid artificial felt and some open cell foam that has started to break down and go sticky and after re-assembly Fs has gone down to 550 but with secondary resonances now

I got my little mosquito clamps and pulled out the factory damping via the pole and it was simply some semi rigid artificial felt and some open cell foam that has started to break down and go sticky and after re-assembly Fs has gone down to 550 but with secondary resonances now

I'm guessing the secondary resonance is a pipe resonance after taking out the long fibre wool I put there a while back?

I might just have to take a saw blade to the plastic and use brute force to remove it but perhaps [ and this is a big "perhaps"] maybe I could use a 16mm spade bit down the hole and drill away enough plastic to allow me to glue something to the rear.

I might just have to take a saw blade to the plastic and use brute force to remove it but perhaps [ and this is a big "perhaps"] maybe I could use a 16mm spade bit down the hole and drill away enough plastic to allow me to glue something to the rear.

Lets see how this experiment goes.

I bought a new spade bit, a plumbing end cap and some special plastic rated superglue.

Very carefully cut out a 25mm hole and glued the end cap over the hole. Just for security and making sure it was airtight I've also run a bead of plumbers silicone around the base of the cap.

I've used some scraps of 3-M Thinsulate and a patch of woollen blanket as the damping, not sure about the woollen blanket but I know Thinsulate works reasonably well.

I'll need to leave them now for at least 8 hours and then I'll test them using my DATS and that should give me an indication, I will need to find some more long fibre wool tho, for the damping in the pole piece

I bought a new spade bit, a plumbing end cap and some special plastic rated superglue.

Very carefully cut out a 25mm hole and glued the end cap over the hole. Just for security and making sure it was airtight I've also run a bead of plumbers silicone around the base of the cap.

I've used some scraps of 3-M Thinsulate and a patch of woollen blanket as the damping, not sure about the woollen blanket but I know Thinsulate works reasonably well.

I'll need to leave them now for at least 8 hours and then I'll test them using my DATS and that should give me an indication, I will need to find some more long fibre wool tho, for the damping in the pole piece

Attachments

Not even 4 hours and the silicone has set well

Interesting results so far

Fs hasn't changed down, it has gone up on one driver and stayed the same on the other. What has gone away are the secondary resonances and while I don't have silver ears they sound cleaner and clearer to me.

I've been simply playing music with a 10uF cap in series

But I did clean out almost all the FerroFluid in the gap and this may have made a difference.

If these were designed to use FF I guess I should buy a bit and replace it, does using FF lower the Fs at all?

Interesting results so far

Fs hasn't changed down, it has gone up on one driver and stayed the same on the other. What has gone away are the secondary resonances and while I don't have silver ears they sound cleaner and clearer to me.

I've been simply playing music with a 10uF cap in series

But I did clean out almost all the FerroFluid in the gap and this may have made a difference.

If these were designed to use FF I guess I should buy a bit and replace it, does using FF lower the Fs at all?

OK but if the driver was designed and sold with FF wouldn't it be better to replace it?

I suppose an Fs of below 700Hz is still reasonable for a tweeter to cross at 2k to an 8" woofer

I suppose an Fs of below 700Hz is still reasonable for a tweeter to cross at 2k to an 8" woofer

or would one applied to the rear outside perimeter of the dome , increasing the moving mass ? I've seen this done to a woofer cone, lowering FS. Just wondering if it could work on such a much smaller diaphragm.a felt doughnut on the top of the pole piece improve anything?

If there's a cylinder there's pipe resonances + any end corrections.I'm guessing the secondary resonance is a pipe resonance after taking out the long fibre wool I put there a while back?

Ideally we want at least -24 dB/4 octaves away with 1st order XO = 2000/2^4 = 125 Hz, 2nd = /2^2 = 500 Hz, 4th = /2 = 1000 Hz, so in theory need 4th orderI suppose an Fs of below 700Hz is still reasonable for a tweeter to cross at 2k to an 8" woofer

- Home

- Loudspeakers

- Multi-Way

- Lowering the Fs of a big tweeter