I love my Linn but somethings wonder around while it plays and forget to cue it at the end of the record. There were a couple of commercial offerings, but they seem to have gone away. Has anyone built a device to lift the arm at the end of play?

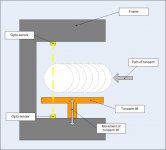

Our local guy, Mandy Marino made Tonal - a tone arm lifter with auto-reset.

See pictures

See pictures

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

It looks like when the arm reaches the lift it trips and rotates to lift. Is that correct? Are they available to purchase? Thanks

About thirty years ago, Monitor Audio made a rather natty little device called "Stylift". It was essentially a vertical post with a pivot sticking out horizontally about halfway up. On the pivot rotated a cylindrical vertical weight with a thin bar sticking past the pivot. The weight was rotated to be at the top (where it was unstable) and the bar rested against a stop. The idea was that the arm would gently knock the cylindrical weight and it would overbalance, the thinner bar would then swing up and collect the arm. Although it sounds bizarre, it worked very well and I successfully made a couple for higher mass arms.

Empire made something like that, too, for their turntables. I used one- once; when the arm hit the trigger, the weight swung around the pivot, lifted the arm, and it kept going. Bounced the stylus off the label, onto the spindle, and sheared the cantilever off neat as you please.

I suspect that a silicone damped arm would be a better candidate for a device like this.

I suspect that a silicone damped arm would be a better candidate for a device like this.

EC8010, what you described seems a lot of work and freightening for the arm

SY, the lifting device I posted I so simple and effective, you should see it in action. No possibility for what you described. It's very popular here, and almost all friends I know with pivoted arms use it.

SY, the lifting device I posted I so simple and effective, you should see it in action. No possibility for what you described. It's very popular here, and almost all friends I know with pivoted arms use it.

I've used the Stylift without the disaster that Sy describes, but it never worked very well, possibly owing to my own ham-handedness. Positioning is very critical, at least on a Sondek, and it was either have it too close to the record's perimeter and lose the last few bars, or have it too close to the centre and have it not lift the arm. It turns out that there are enough out-of-spec records that both of these events happened too often for my liking even when the device was in the exact right spot. So I gave up on it.

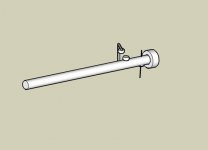

I have fantasized about, but never built nor even properly designed, a lift which would use an optical sensor to trigger a (hydraulic? magnetic?) lift arm - see the drawing, which shows a plan view. Ideally, I suppose, a second optical sensor mounted towards the outside would reset the lift to its lowest point when you moved the arm back out.

Regards.

Aengus

[edit: grammar fix ...and typos

...and typos  ]

]

I have fantasized about, but never built nor even properly designed, a lift which would use an optical sensor to trigger a (hydraulic? magnetic?) lift arm - see the drawing, which shows a plan view. Ideally, I suppose, a second optical sensor mounted towards the outside would reset the lift to its lowest point when you moved the arm back out.

Regards.

Aengus

[edit: grammar fix

...and typos

...and typos  ]

]Attachments

Yes, I was aware that a lot of people didn't like the Stylift. I think it's great and I have one on my SME3009S2 and would have one on my homebrew arm except that I failed to leave room for it. It's true that ou-of-spec. records cause problems, but you can't blame that on the mechanism, more the record. John Martyn's "One World" is a case in point, with a ridiculously small recorded diameter.

Agreed, not the fault of the mechanism, but frustrating nonetheless. The real issue, I suppose, is whether the geometry of one's particular table and arm allow positioning the Stylift far enough away from the arm pivot that the arm has significant lateral motion at the Stylift. Ideally suited to 12" arms, perhaps?

On looking at my previous post, even two edits were apparently insufficient. I meant to say that the drawing showed an elevation, not a plan view.

Regards.

Aengus

On looking at my previous post, even two edits were apparently insufficient. I meant to say that the drawing showed an elevation, not a plan view.

Regards.

Aengus

About a million years ago I had a lifting mechanism on my Rega P2. It didn't have suitable damping, so there was a lot of tonearm bouncing, which bothered me, so I put it back in the box. I haven't used one since.

Jeff

Jeff

Aengus said:--

I have fantasized about, but never built nor even properly designed, a lift which would use an optical sensor to trigger a (hydraulic? magnetic?) lift arm - see the drawing, which shows a plan view. Ideally, I suppose, a second optical sensor mounted towards the outside would reset the lift to its lowest point when you moved the arm back out.

Regards.

Aengus

I once had a similar plan, and some nice "reflector"-sensors, that did not need the big pillar...

(The sensors came from an old copy-machine, for detecting paper).

And the lift could drop as soon as the arm was taken out of the zone...

Arne K

Would it be ok to just turn the motor of the TT off when the sensor detects the arm, rather than mechanically lifting the arm? This would leave the stylus stoped in the run out groove. is this a problem?

Something I have been thinking about for a while now.

Something I have been thinking about for a while now.

Nanook said:

Hi Nanook

I've seen something similar tried. The problem is that as soon as the magnet on the tonearm starts to get within range of the stationary magnet, it starts to lift and drag the tonearm across the remaining grooves - an ugly sight (and sound). I suppose one could interpose shielding material to make the magnetic connection wait until everything was almost aligned, but it seems it would be tricky.

Regards.

Aengus

seems if some use magnets as a means for anti-skating, couldn't one use magnets for a lift?

Hi Nanook

I've seen something similar tried. The problem is that as soon as the magnet on the tonearm starts to get within range of the stationary magnet, it starts to lift and drag the tonearm across the remaining grooves - an ugly sight (and sound). I suppose one could interpose shielding material to make the magnetic connection wait until everything was almost aligned, but it seems it would be tricky.

Regards.

Aengus

Aengus....

obviously I was thinking about having the ability to adjust the distance between the magnets (and also trying varying strengths of them). It may work, it may not but may be worth a try. If magnets can be used to adjust anti-skating, why couldn't they be used as a lift.? Again, this is only an idea.

stew

obviously I was thinking about having the ability to adjust the distance between the magnets (and also trying varying strengths of them). It may work, it may not but may be worth a try. If magnets can be used to adjust anti-skating, why couldn't they be used as a lift.? Again, this is only an idea.

stew

In the early 80's I had a device that was hydraulic triggered by a small lever the tone arm hit. I don't think it was the sylift mentioned here. I later built an optical device that the tone arm triggered and shut off the motor. it worked very well.

obviously I was thinking about having the ability to adjust the distance between the magnets (and also trying varying strengths of them).

Hey Stew

Yep, not saying it can't be made to work. Just that the implementation I saw clearly demonstrated that dragging the arm laterally was a problem that would have to be overcome.

I suppose one could adapt the optical device I proposed earlier to trigger a lever that moves the magnet within range once the stylus is in the run-out grooves. But as you say, it may be possible just by carefully tuning magnet strength and distance.

You have to remember, though, I'm the guy who couldn't even get the Stylift working properly, so fine-tuning mechanical bits is obviously not one of my strengths.

Regards.

Aengus

Hi, mandym here, reporting for duty.

I am the fellow who arnoldc referred to as the maker of the arm lifter "Tonal". I will gladly answer your questions through this forum and will encourage members to build their own. Nanook come close, real close to the operation of the gadget. The problem about the stylus being dragged across the record surface is solved through a teeter-totter system that triggers the pick-up magnet to attract the arm straight up vertically. It does not launch the arm in orbit, all one hears is a very light thump to announce a "successful lift-off".

I have sent a video of the Tonal in operation to Badge. Maybe he can be badgered to show it?

mandym

I am the fellow who arnoldc referred to as the maker of the arm lifter "Tonal". I will gladly answer your questions through this forum and will encourage members to build their own. Nanook come close, real close to the operation of the gadget. The problem about the stylus being dragged across the record surface is solved through a teeter-totter system that triggers the pick-up magnet to attract the arm straight up vertically. It does not launch the arm in orbit, all one hears is a very light thump to announce a "successful lift-off".

I have sent a video of the Tonal in operation to Badge. Maybe he can be badgered to show it?

mandym

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- looking for a DIY end of record lift for a manual tt